High-concentration organic wastewater direct deep purification method

A technology for deep purification of organic wastewater, applied in chemical instruments and methods, temperature condition water treatment, reflux water treatment, etc., can solve inappropriate problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

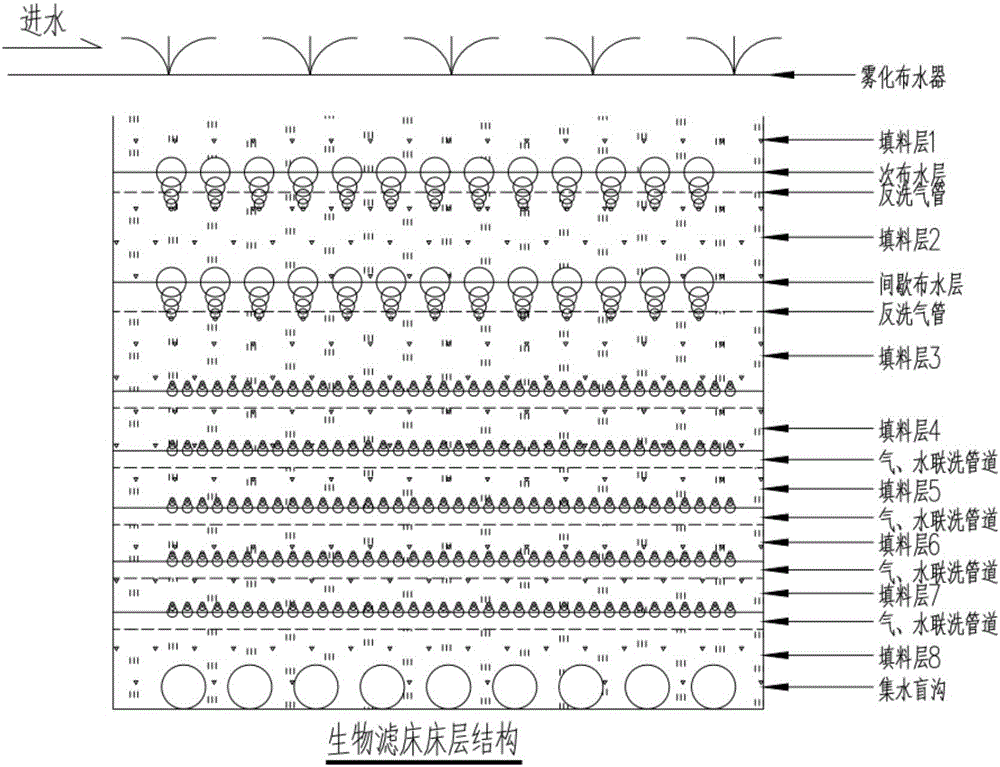

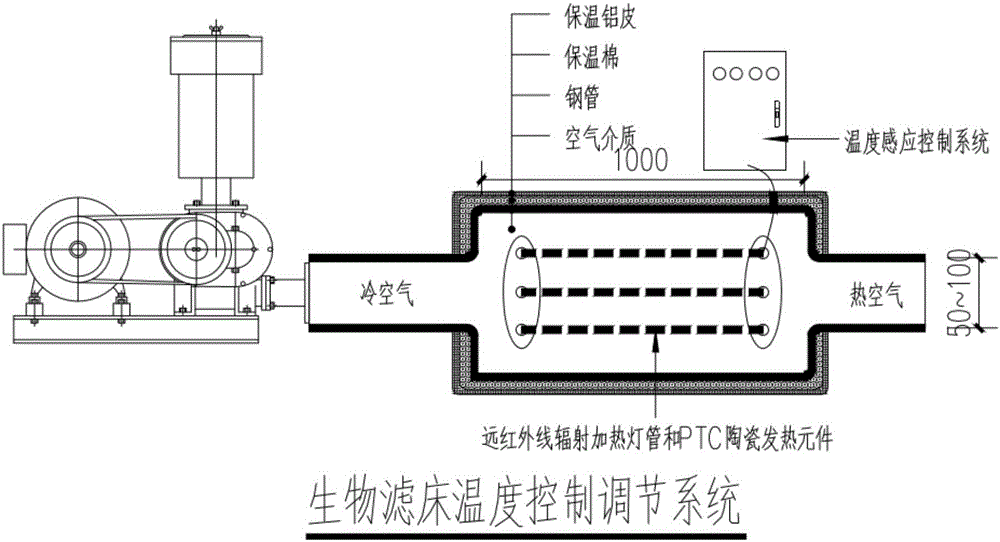

[0031] A method for direct deep purification of high-concentration organic wastewater, comprising the following steps:

[0032] (1) Enhanced precipitation treatment: including dosing coagulation unit, coagulant includes polyaluminum chloride, polyferrous sulfate; dosing flocculation unit, flocculant includes cationic polyacrylamide, anionic polyacrylamide, non-ionic polypropylene Amide; physical precipitation unit, through the compression double layers of chemical agents, adsorption neutralization, adsorption bridging, sediment net capture and other mechanisms, the fine suspended particles and colloidal ions in water are destabilized, aggregated, flocculated, coagulated, and precipitated . The present invention generally selects partition flocculation tanks, mechanical flocculation tanks, folding plate flocculation tanks, and grid flocculation tanks.

[0033] a. Partition flocculation tank: ①The flocculation time is generally selected to be 20-30min; ②The flow velocity of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com