A Surface Modification Method for Changing the Surface Wettability of Impregnated Graphite

A technology of impregnating graphite and surface infiltration, which is applied in the field of surface modification of solid materials, can solve the problems of complex steps, inability to change infiltration properties, and high difficulty in coating realization, and achieves the effect of simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

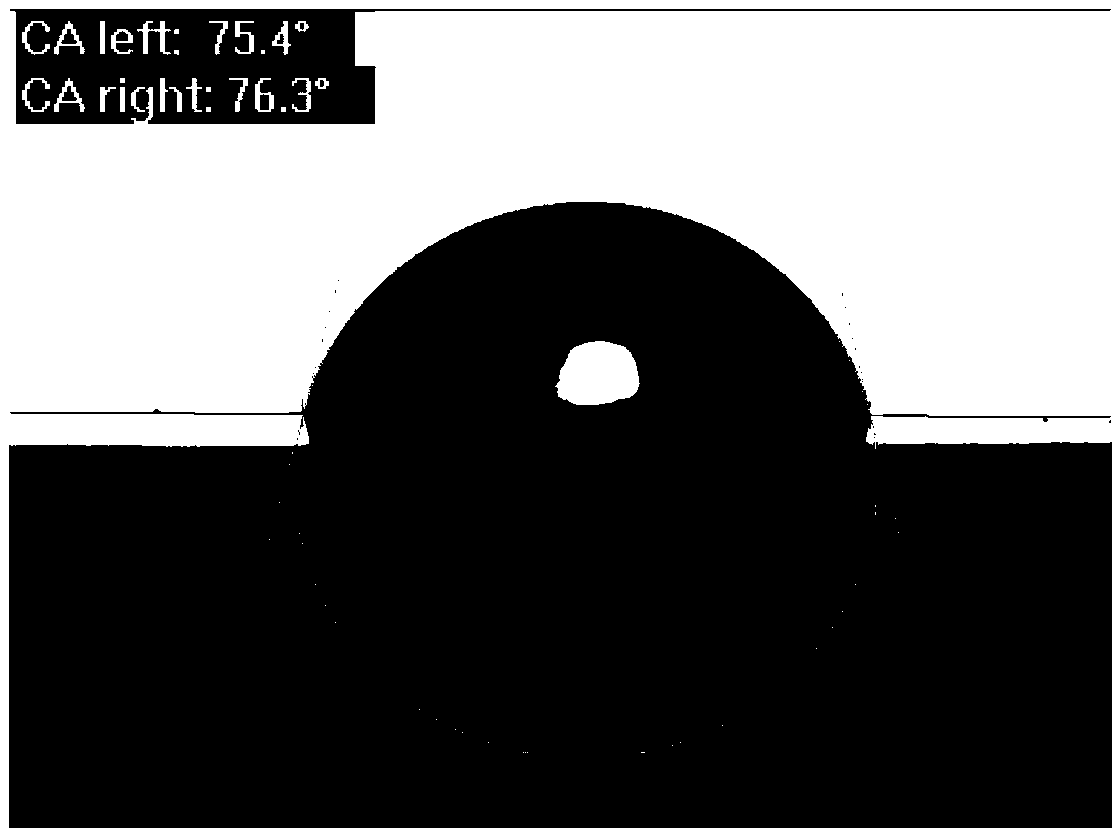

[0030] Before laser modification, the surface contact angle measured by surface tensiometer was 75.6°, as figure 1 shown in . Set the laser scanning speed to 2000mm / s, the laser repetition frequency to 20kHz, the laser power to 12.5W, and the number of scans to 1. After the local area is irradiated, the surface contact angle measured by the surface tensiometer becomes 17.2°, as figure 2 Shown at left.

Embodiment 2

[0032] The surface contact angle measured by surface tensiometer before laser modification was 75.6°. Set the laser scanning speed to 2000mm / s, the laser repetition frequency to 20kHz, the laser power to 10W, and the number of scans to 1. After irradiating the local area, the surface contact angle measured by the surface tensiometer becomes 47.3°, as figure 2 shown on the right.

Embodiment 3

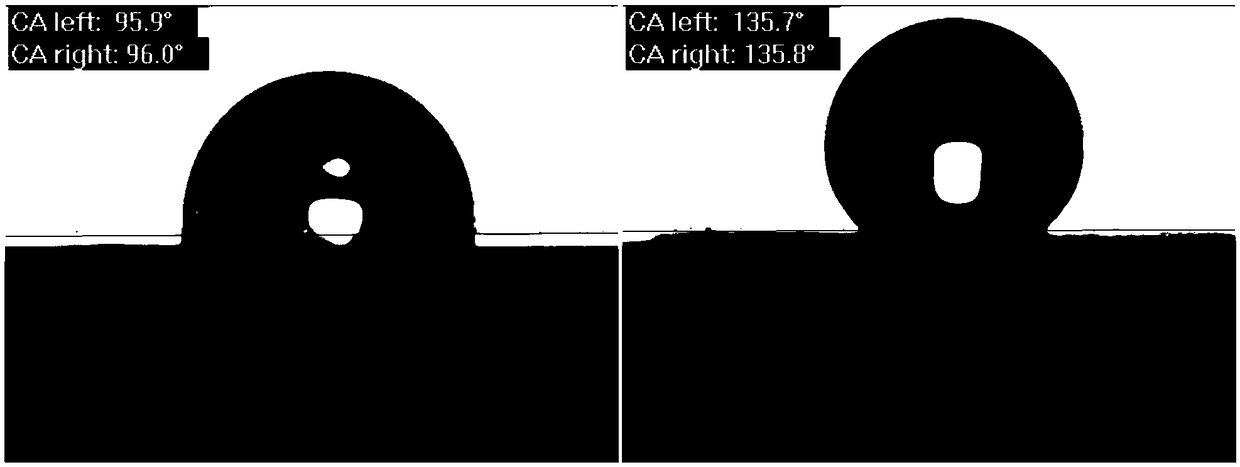

[0034] The surface contact angle measured by surface tensiometer before laser modification was 75.6°. Set the laser scanning speed to 2000mm / s, the laser repetition rate to 20kHz, the laser power to 7.5W, and the number of scans to 1. After irradiating the local area, use the surface tensiometer to measure the surface contact angle to 96°, as image 3 Shown at left.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com