Polishing device

A kind of equipment and polishing head technology, applied in the field of processing and manufacturing, can solve problems such as limited force, affecting product quality, and obvious marks on the surface of the mold core, so as to achieve the effect of ensuring quality and improving surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. The "front", "rear", "left", "right", "upper" and "lower" mentioned in the text all refer to the placement state in the drawings.

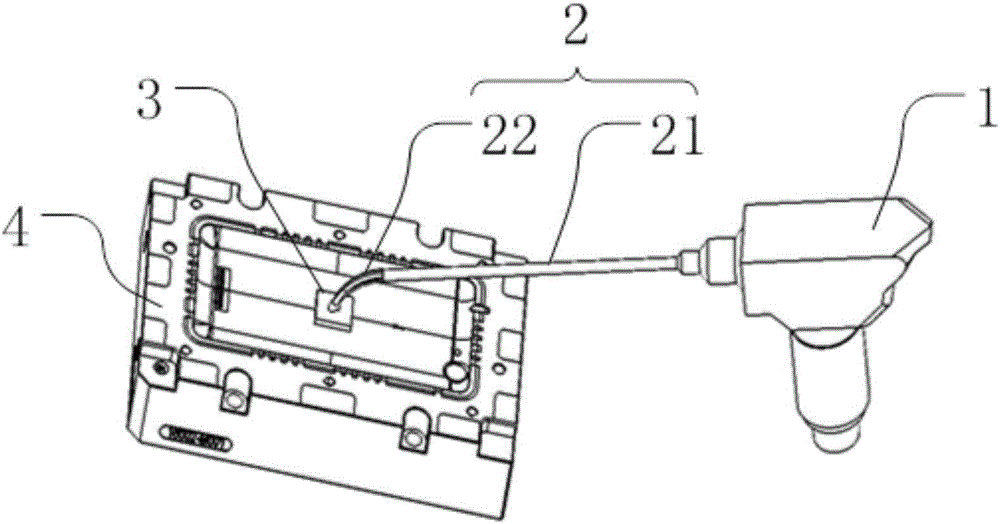

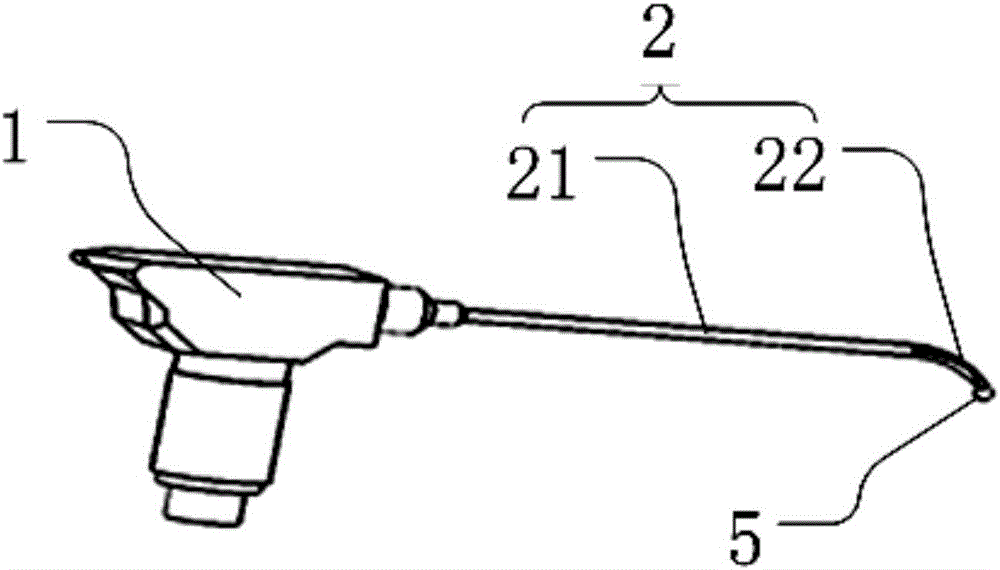

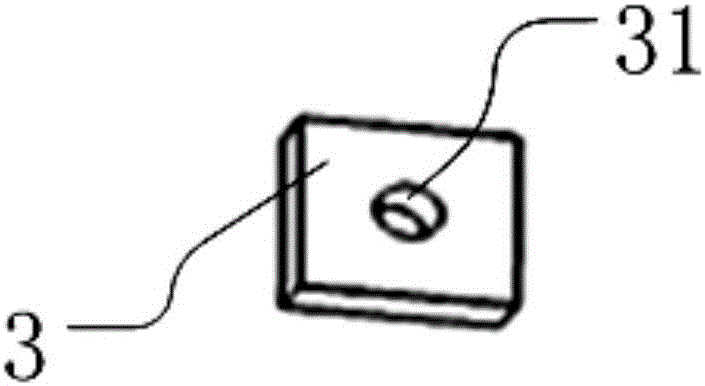

[0036] Such as Figure 1-2 As shown, the embodiment of the present application provides a polishing device, including a driving mechanism 1, a transmission structure 2 and a polishing head 3, the driving mechanism 1 is an ultrasonic driver, and is provided with an output hole; one end of the transmission structure 2 is connected to the output hole, The other end is detachably connected to the polishing head. Since the polishing head 3 is a wearing part, the detachable connection can facilitate the replacement of the polishing head 3; the transmission structure 2 and the polishing head 3 are made of different materials, and the polishing head 3 is stronger than the transmission structure 2 low int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com