A graphene battery thermal management device

A battery thermal management and graphene technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of no low-temperature heat preservation function and low cooling efficiency of micro-channels, achieve low-temperature heat preservation temperature difference, reduce temperature difference, The effect of increasing fitness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

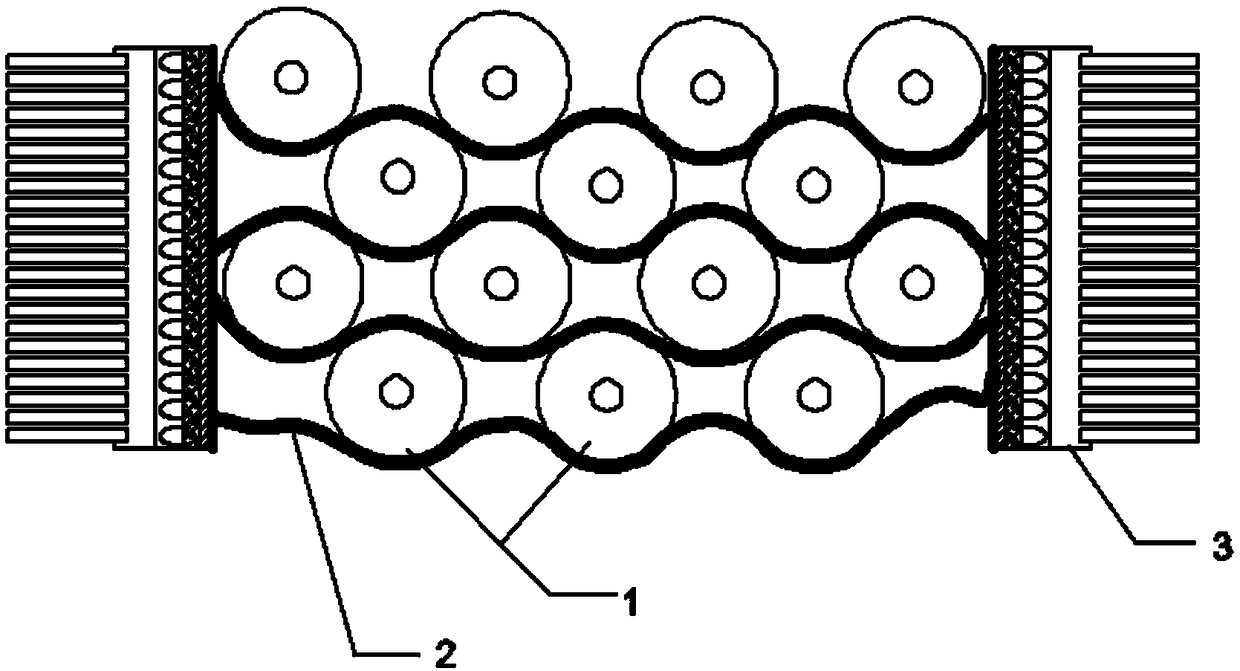

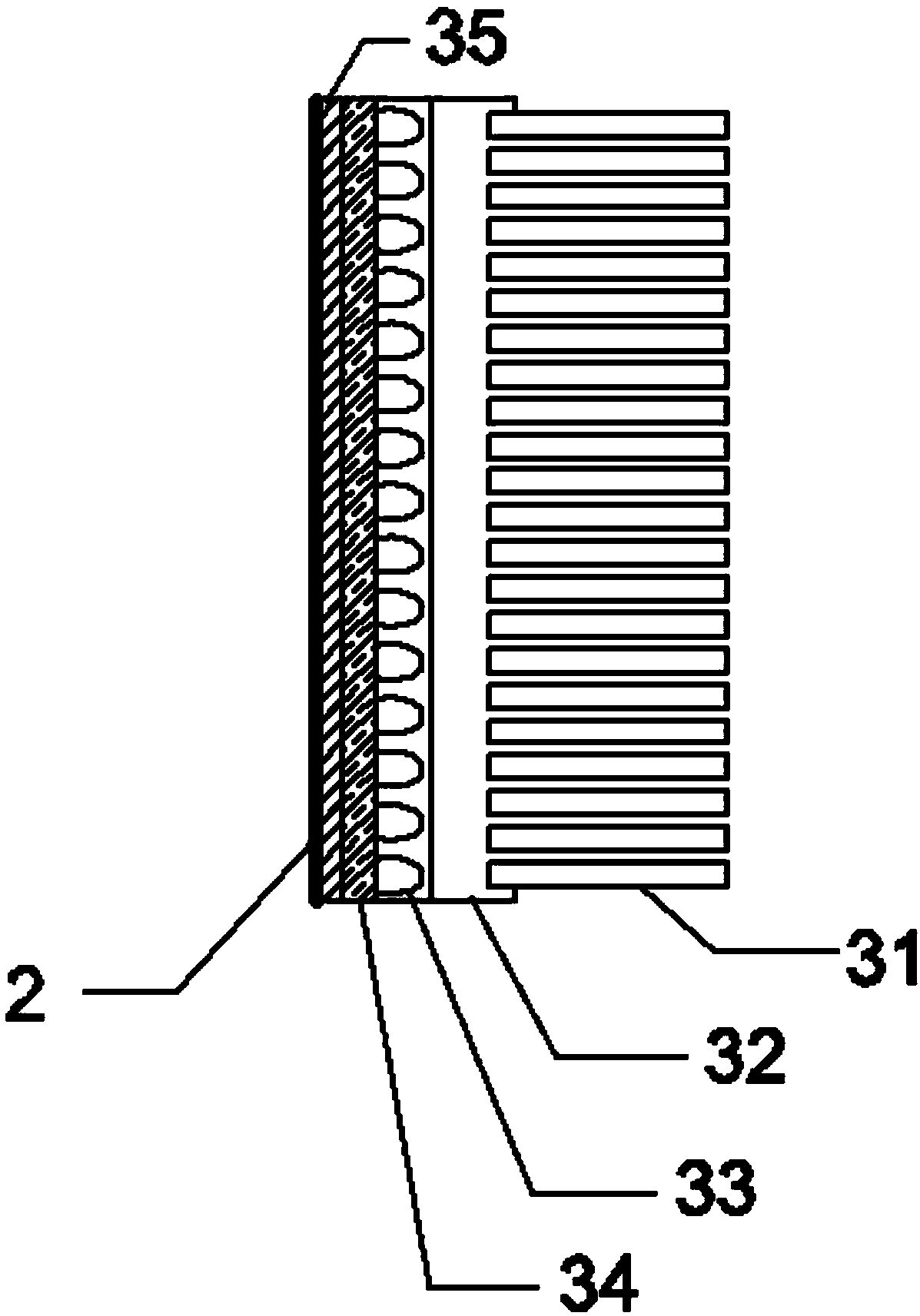

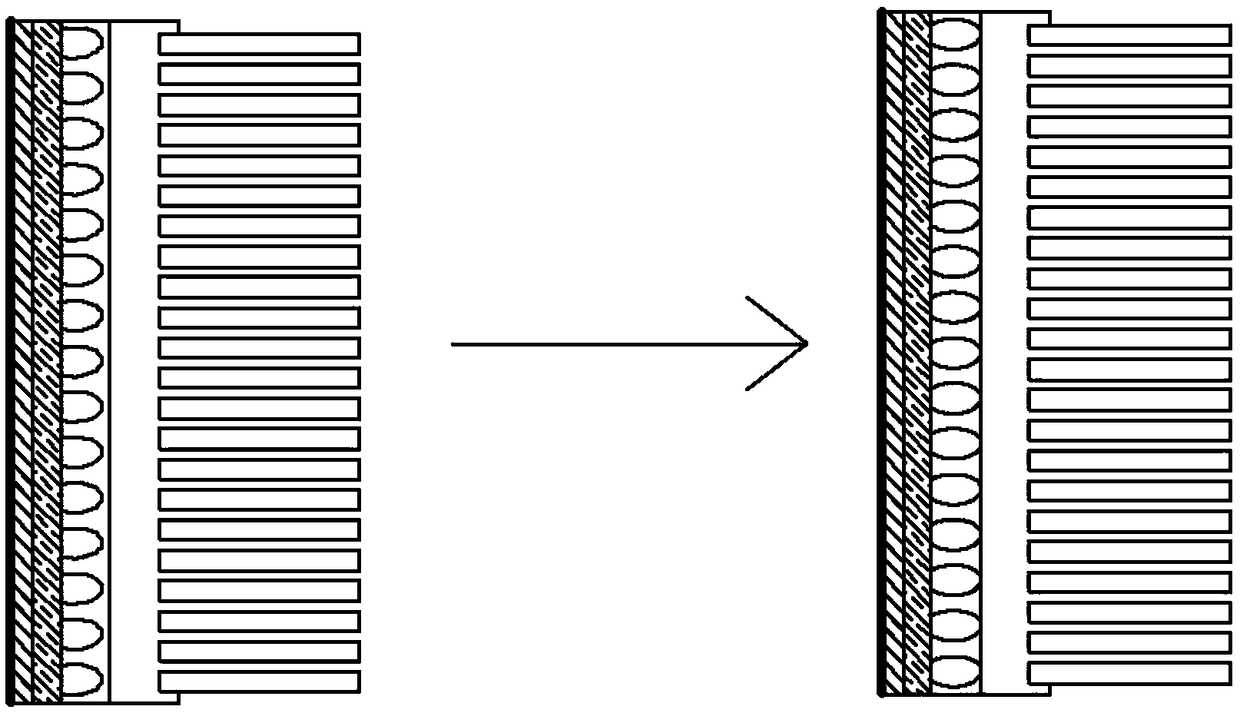

[0023] Such as figure 1 As shown, a graphene battery thermal management device includes several battery cells 1, graphene film 2 and automatic heat dissipation insulation grid 3; some of the battery cells 1 form a battery pack, and the middle part of the graphene film 2 and the The battery cell 1 housing contacts, such as figure 2 As shown, the automatic heat dissipation heat preservation grid 3 includes a heat dissipation grid 31 and a heat dissipation contact 33. The heat dissipation grid 31 is arranged on the grid base 32, and the heat dissipation contact 33 is arranged on the contact base 34. The grid base 32 is fixedly connected to the contact base 34, and a cavity for accommodating the heat dissipation contact 33 is arranged between the two, and the two ends of the graphene film 2 are bonded to the contact base 34 The thermally conductive adhesive material of the layer 35 is bonded. In this embodiment, the thermally conductive adhesive material is thermally conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com