Digital detecting method of bending angle of sheet metal part

A technology of bending angle and detection method, applied in the direction of electrical digital data processing, design optimization/simulation, special data processing applications, etc., can solve the problems of waste of process resources, inability to collect product data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0034] The invention proposes a digital detection method for the bending angle of sheet metal parts, which is characterized in that the part design model is used as a reference model to scan the point cloud model C of the formed part O Processed to detect flange bend angles of formed parts. Specific steps are as follows:

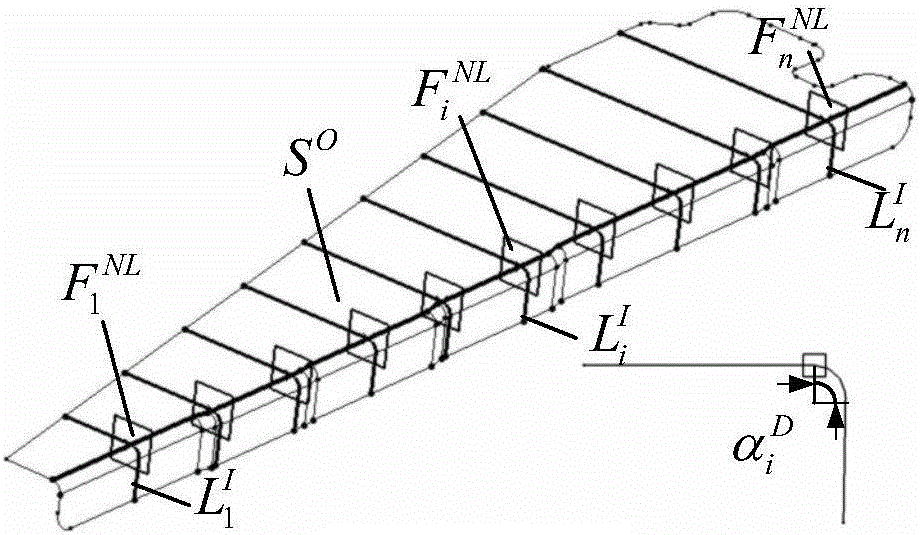

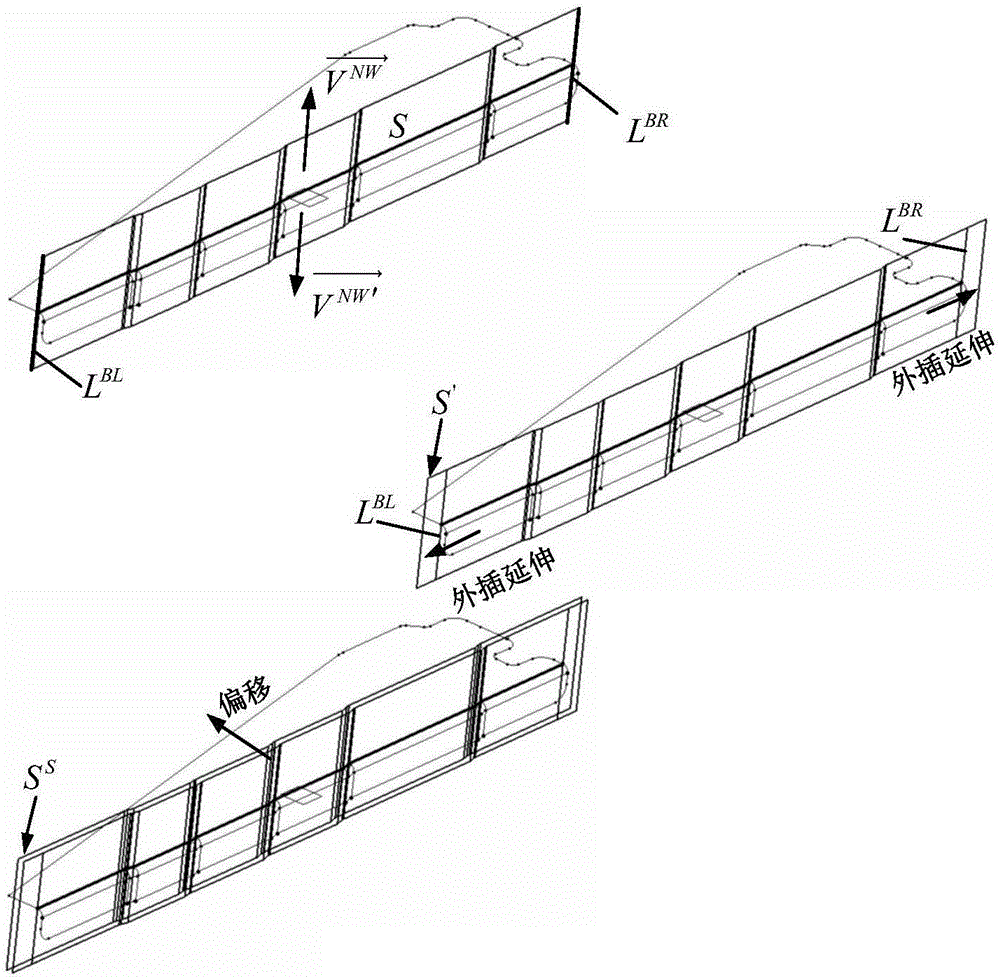

[0035] Step 1: Establish the outline surface point cloud model C of the part design model D , to extract the flange baseline L of the part design model IW , establish normal plane, point cloud model segmentation surface S S , point cloud model segmentation plane F S ,Specific steps are as follows:

[0036] Step 1.1: Extract the outer surface S of the part design model O , the outer surface S O Export to get the design model outline su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com