Remote multi-dump-pit data acquisition and recording system

A data acquisition and recording system technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of management systems without garbage pit storage and fermentation analysis, so as to improve management level and reduce calorific value changes Larger, guaranteed stability and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A multi-remote garbage pit data collection and recording method, comprising the following steps;

[0062] Step 1. Determine and record the transfer and turning of garbage in each area through the material level gauge;

[0063] The material level gauge can test the material level and material level distribution of the detected unit in real time, and can monitor the garbage transfer and turning of the garbage crane in each section in real time.

[0064] Step 2. Use the material level gauge and infrared thermometer to detect the maturity of the garbage fermentation by the change of the internal temperature of the garbage during the turning process;

[0065] The combination of material level gauge and infrared thermometer can test the temperature of the surface layer of the garbage in the process of garbage transfer and turning in the detected unit in real time, and the temperature of the surface and interior of the garbage in each section can be real-time to prompt the mat...

Embodiment 2

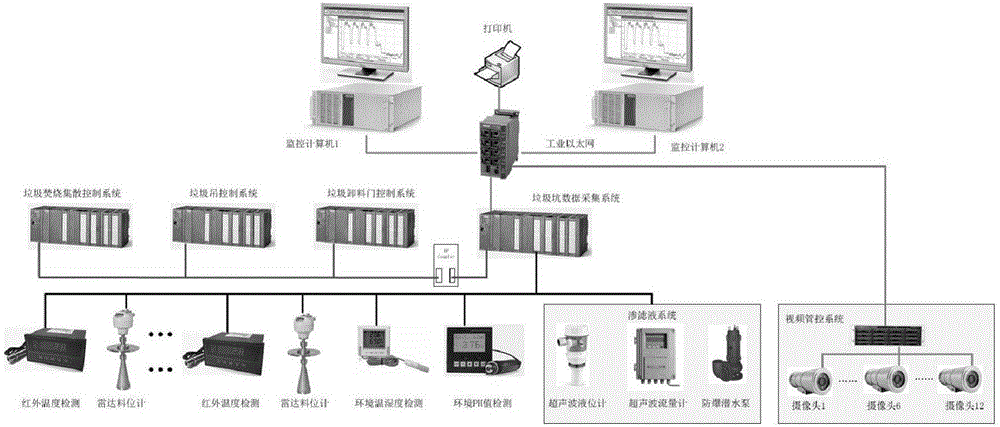

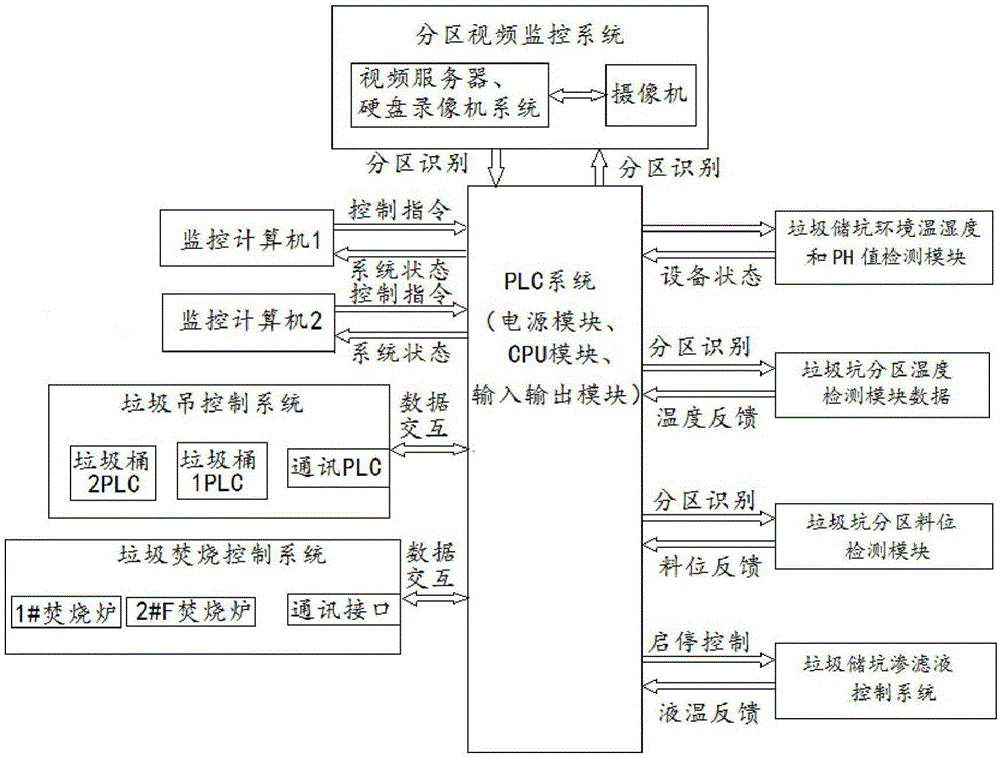

[0080] A garbage storage pit comprehensive monitoring system includes a control hardware part and a software logic operation part.

[0081] Control hardware includes radar level gauge, infrared thermometer, environmental temperature and humidity detection, environmental PH value detection, video system, man-machine interface part, control unit, input / output module;

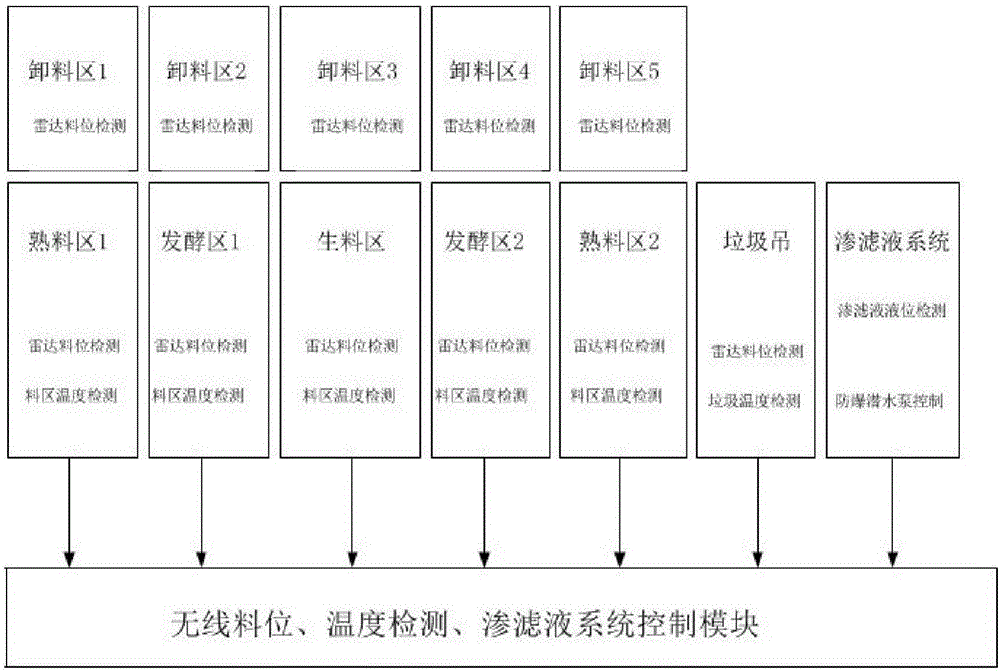

[0082] The control system is managed based on the zoning of the garbage pit, which is planned as raw material area, fermentation area and clinker area according to the size of the storage pit.

[0083] Determine and record the transfer and turning of garbage in each area through the material level gauge;

[0084] Use level gauges and infrared thermometers to detect the maturity of garbage fermentation by changing the internal temperature of garbage during the turning process;

[0085] By communicating with the garbage crane control system to determine the specific location of the garbage crane in that area and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com