Heating test circuit and heating test system for fuel cell stack

A fuel cell stack and test circuit technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., to achieve the effects of simplifying experimental devices, reducing experimental costs, and reducing waste of time and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

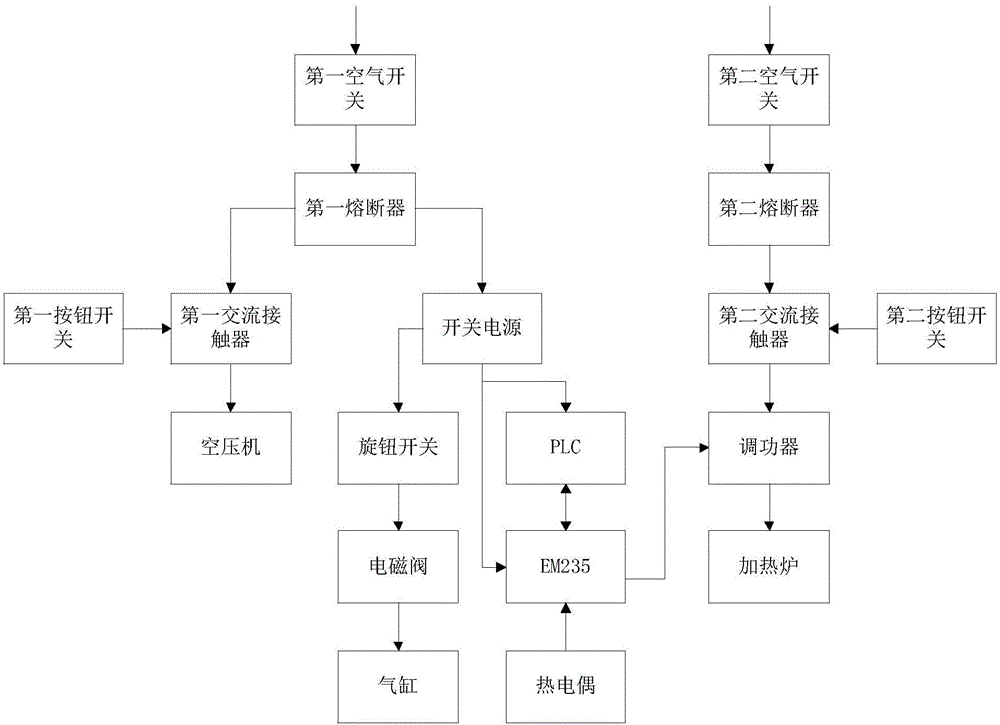

[0027] In the corresponding mechanical device in a fuel cell stack heating test circuit of the present invention, the stack is arranged in the heating furnace, the hydrogen tank feeds hydrogen into the heating furnace, and the air compressor feeds hydrogen into the heating furnace. Air is introduced, the cylinder is set above the heating furnace and pressurizes the electric stack located in the heating furnace, and the temperature detection circuit (referred to as a thermocouple sensor in this embodiment) extends into the heating furnace And detect the real-time temperature in the heating furnace.

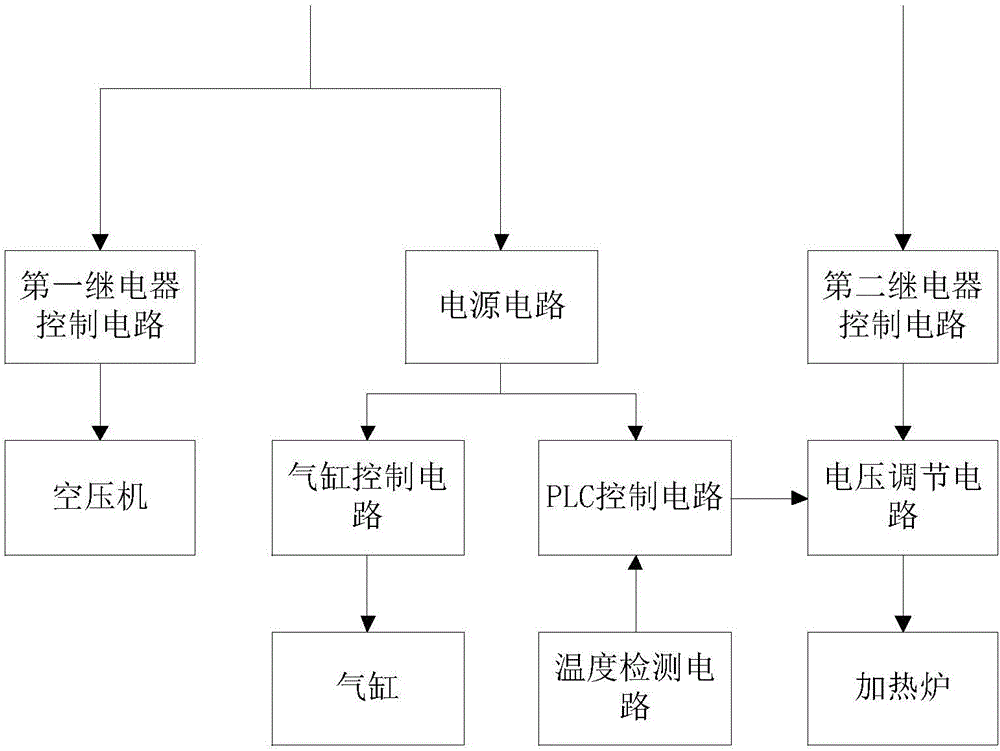

[0028] Such as figure 1 As shown, a fuel cell stack heating test circuit includes a first relay control circuit, a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com