Automatic testing method

A technology of automatic testing and testing equipment, applied in the direction of measuring electricity, measuring equipment, measuring electrical variables, etc., can solve the problem of low testing efficiency and achieve the effect of improving testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

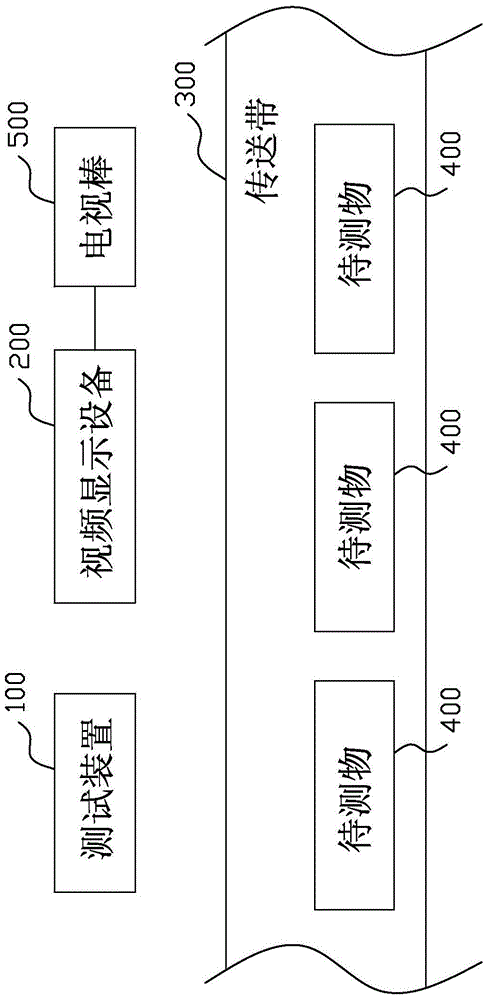

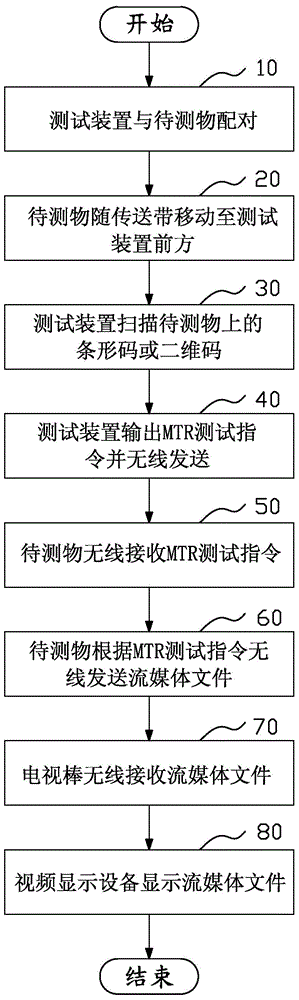

[0022] see figure 1 and figure 2 As shown, the present invention provides an automatic testing method, which uses a testing device 100 and a video display device 200 to test a plurality of DUTs 400, and the testing device 100 and the video display device 200 are installed on one side of a conveyor belt 300 And it has a wireless transmission function, and the test device 100 outputs MTR test instructions; a TV stick 500 is connected to the video display device 200; the object under test 400 moves with the conveyor belt 300, and the object under test 400 has a wireless transmission function And live test function; And described automatic test method comprises the following steps:

[0023] Step 10: Pair the test device 100 with the object under test 400; execute step 20 after the pairing is successful; if the pairing is unsuccessful, end the process;

[0024] Step 20: the object under test 400 moves to the front of the testing device 100 along with the conveyor belt 300;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com