Method for directly measuring winding loss of magnetic component

A technology of winding loss and magnetic components, applied in the field of direct measurement of winding loss of magnetic components, can solve the problems of inability to realize on-line measurement of winding loss of magnetic components in power converters and has great influence, and achieve the effect of convenient measurement and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

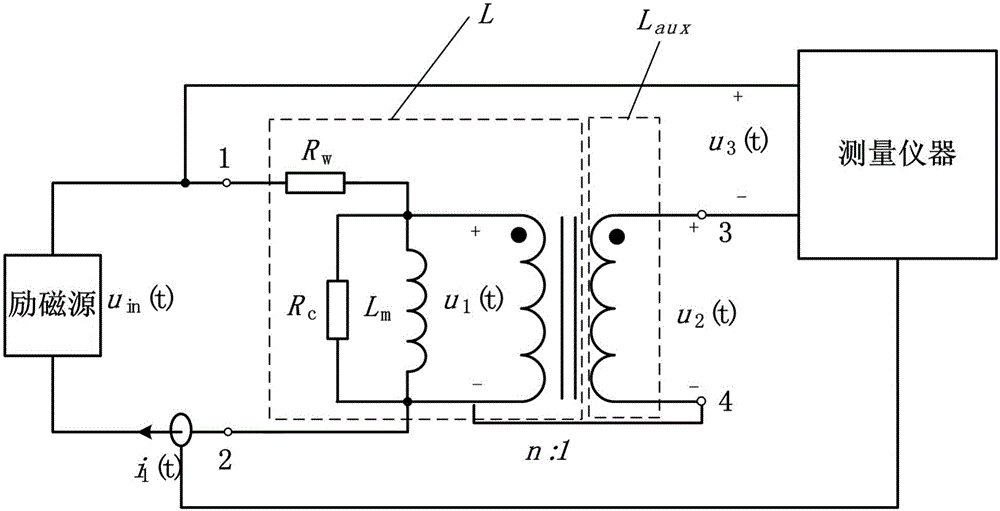

[0025] Such as figure 1 As shown, the first embodiment of the present invention aims at the measurement of the measured inductive winding loss when the turns ratio n of the measured inductive winding and the auxiliary winding is 1. For the measured inductor winding and auxiliary winding turn ratio n is 1, the measured inductor winding loss measurement. The excitation source can be composed of a signal generator and a power amplifier, or it can be the actual excitation waveform at both ends of the magnetic element in the actual power converter; L is the measured inductance, where R w Is the equivalent resistance of the measured inductor winding, which reflects the winding loss of the inductor, R c In order to reflect the equivalent resistance of the measured inductor core loss, L m Is the magnetizing inductance of the measured inductance, L aux Is the auxiliary winding, terminal 1 and terminal 2 are the two pins of the measured inductance L, terminal 3 and terminal 4 are the two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com