Low-temperature urea crystal simulation test system for SCR catalytic silencer

A simulation test system, catalytic muffler technology, applied in the direction of internal combustion engine testing, etc., can solve problems such as insufficient pyrolysis and hydrolysis of urea, influence on diesel engine exhaust treatment, and low test efficiency, so as to reduce workload, accurately evaluate crystallization performance, and reduce test The effect of expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

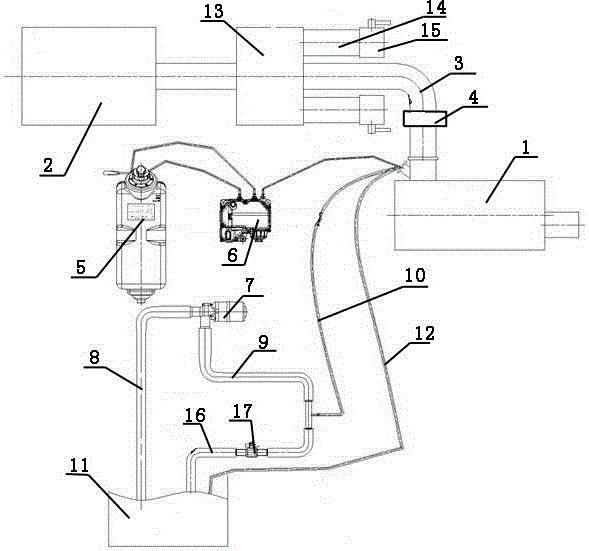

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, a low-temperature urea crystallization simulation test system for an SCR catalytic muffler includes a hot blast system, a urea injection system, a nozzle cooling system and a SCR catalytic muffler 1 to be tested. The hot blast system includes a hot blast device 2, a hot blast pipeline 3 and a section The flow valve 4 and the air outlet of the hot air equipment 2 are connected to the air inlet of the SCR catalytic muffler 1 to be tested through the hot air pipeline 3. A splitter box 13 is arranged on the hot air duct 3 between them. The air outlet of the hot blast device 2 is connected to the air inlet of the splitter box 13. The splitter box 13 is provided with three air outlet holes, and the middle one is connected through the hot air duct 3. The air inlet of the SCR catalytic muffler 1 to be tested is provided with a throt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com