Remote monitoring device for early warning of pumping unit failure

A remote monitoring device and fault warning technology, applied in construction and other directions, can solve the problems of increasing labor costs, time-consuming and laborious management and maintenance, and incompatibility with production needs, and achieve the effects of saving labor costs, improving management efficiency, and cost-effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

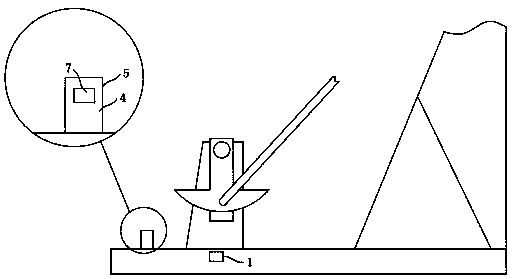

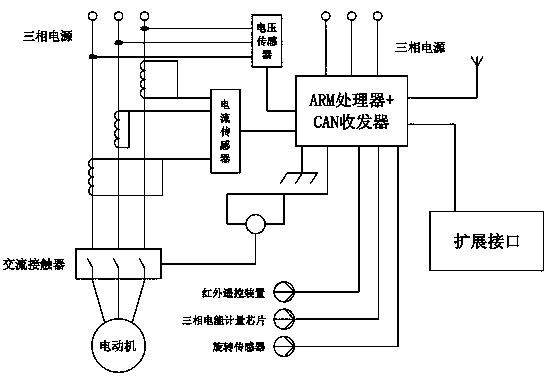

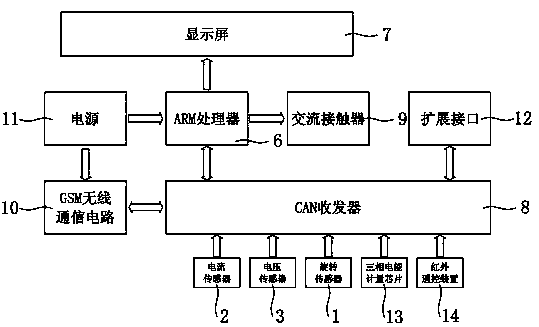

[0013] The pumping unit failure early warning remote monitoring device of the present invention will be further described below in conjunction with the accompanying drawings:

[0014] The remote monitoring device for failure early warning of the pumping unit of the present invention is composed of a rotation sensor 1 , a current sensor 2 , a voltage sensor 3 and a monitoring terminal 4 .

[0015] Among them, the rotation sensor 1 is installed on the pumping unit base below the crank device of the pumping unit, that is, the rotating mechanism of the pumping unit, close to the rotating mechanism, and is located at the edge of the rotating radius of the rotating mechanism. It adopts an inductive proximity sensor (Schneider OsiSense XS series ), and every time the rotation mechanism of the pumping unit rotates one cycle, it must pass through the rotation sensor 1 to generate an electrical pulse, which is sent to the ARM processor 6 to detect and record the rotation cycle time.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com