Wall tile hollowing-prevention inlaying construction method

A construction method and ceramic tile technology, which is applied in the direction of construction and building construction, etc., can solve the problems of rapid loss of mortar, gap extrusion and cracking, etc., so as to improve work efficiency, prevent hollowing, and prevent base cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

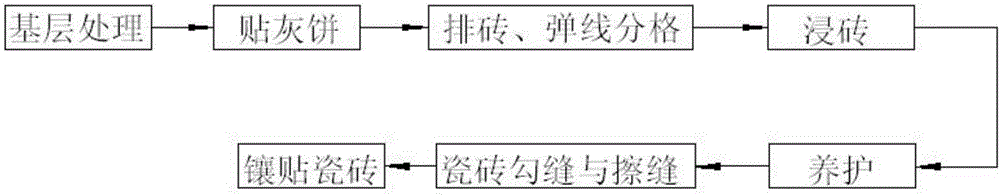

[0042] A wall tile anti-aircraft drum inlaid construction method, such as figure 1 shown, including the following steps:

[0043] Step 1, basic treatment

[0044] Before pasting the tiles, clean the surface of the base layer first, remove the residual slurry and burrs on the wall and inner corners, and use a 2m vertical measuring ruler to check the verticality of the facade; use a 2m measuring ruler and a feeler gauge to check the smoothness of the surface Spend;

[0045] In the first two days of construction, use watering tools to water the base wall.

[0046] The masonry wall surface needs to be watered and moistened again before masonry to ensure that the wall is moist and it is advisable to see no visible water.

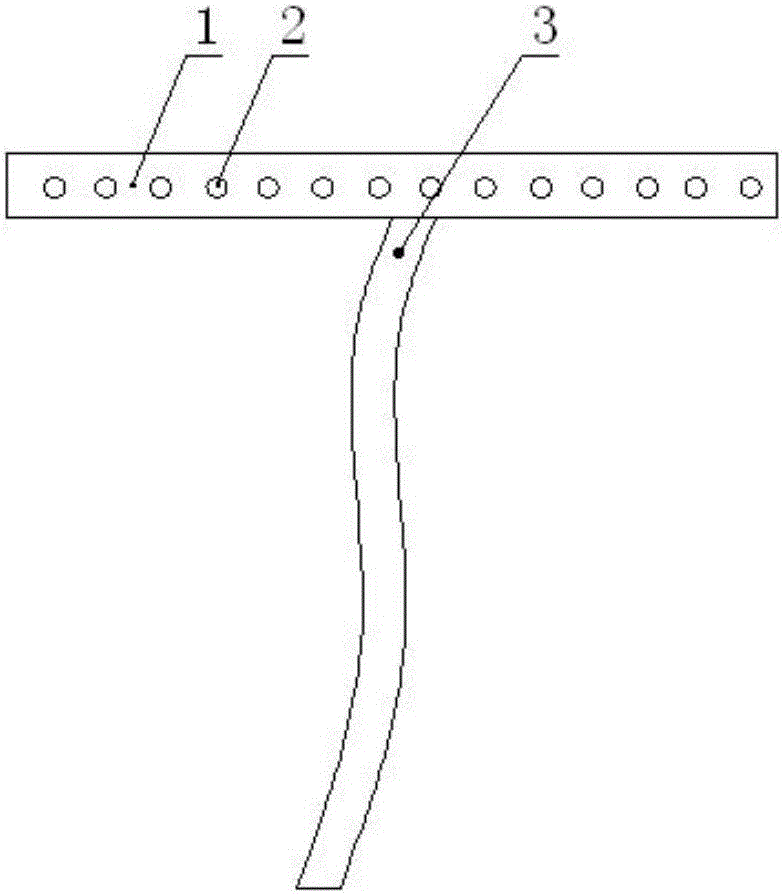

[0047] The watering tools such as figure 2 As shown, it includes a water pipe 3 and a horizontal pipe 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com