Method for preparing nanocellulose from low-strength ultrasonic-assisted amino acid ionic liquid and application of nanocellulose

A technology of nano-cellulose and ionic liquids, applied in fiber raw materials, fiber raw material processing, raw material separation, etc., can solve the problems of high energy consumption of physical and mechanical methods, long time consumption of biological methods, high cost of chemical methods, etc., and achieve simple equipment and operation , good chemical stability, rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing nanocellulose from amino acid ionic liquids assisted by low-intensity ultrasonic waves in this embodiment, the specific preparation steps are as follows:

[0032] (1) Pretreatment of amino acid ionic liquid: uniformly mix crushed 30-mesh corn stalk and glycylic amino acid ionic liquid at 60° C. in a mass ratio of 1%, and obtain the mixture after 1.0 hour of treatment;

[0033] (2) Ultrasonic treatment: the solid-liquid mixture obtained in step (1) was placed in an ultrasonic water bath for ultrasonic treatment for 10 minutes at an ultrasonic power of 50W, and the temperature was controlled at 25°C;

[0034] (3) Post-treatment: centrifuge the mixture obtained in step (2) at 3000 rpm for 10 min; finally freeze-dry at -60° C. for 12 hours to obtain solid nanocellulose.

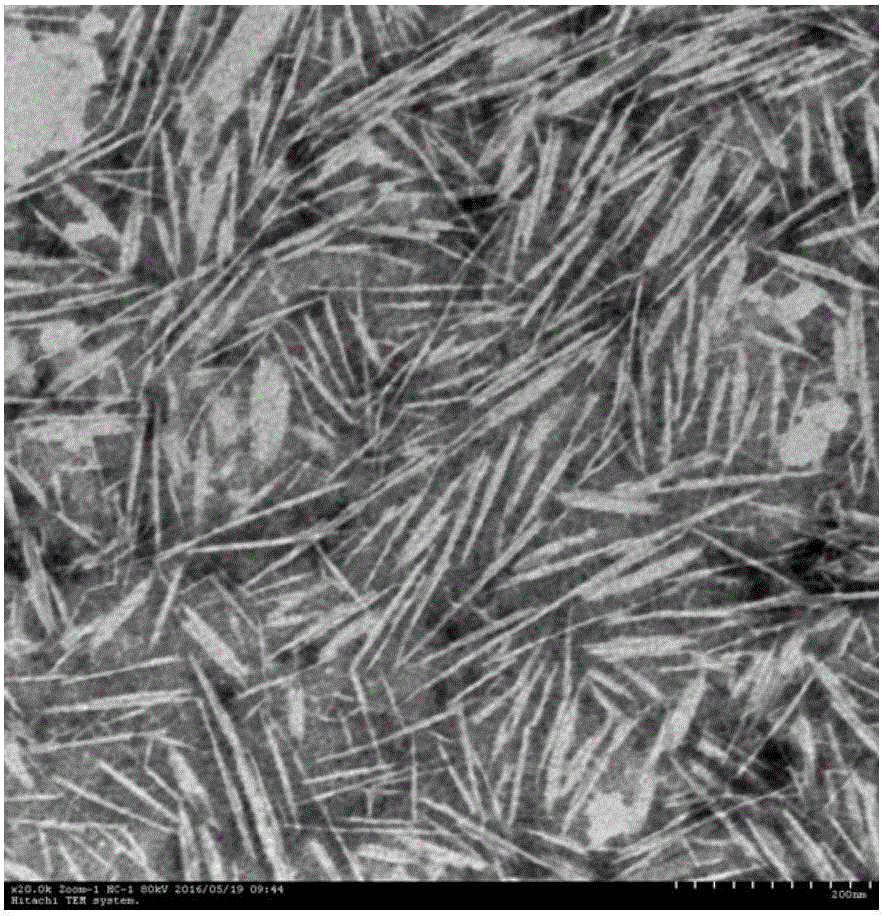

[0035] The performance index of the nanocellulose prepared in this example: yield: 38.21%; diameter: 65-284 nm; length: 223-1286 nm, crystallinity: 82.93%.

Embodiment 2

[0037] A method for preparing nanocellulose from amino acid ionic liquids assisted by low-intensity ultrasonic waves in this embodiment, the specific preparation steps are as follows:

[0038] (1) Pretreatment of amino acid ionic liquid: uniformly mix crushed 40-mesh corn stalk and glycylic amino acid ionic liquid at 60° C. in a mass ratio of 2%, and obtain the mixture after 2.0 hours of treatment;

[0039] (2) Ultrasonic treatment: the solid-liquid mixture obtained in step (1) was placed in an ultrasonic water bath for ultrasonic treatment for 20 minutes at an ultrasonic power of 50W, and the temperature was controlled at 25°C;

[0040] (3) Post-treatment: the mixture obtained in step (2) was centrifuged at 4000 rpm for 10 min; and finally freeze-dried at -60° C. for 12 hours to obtain solid nanocellulose.

[0041] The performance index of the nanocellulose prepared in this example: yield: 38.03%; diameter: 55-242 nm; length: 197-1186 nm, crystallinity: 83.17%.

Embodiment 3

[0043] A method for preparing nanocellulose from amino acid ionic liquids assisted by low-intensity ultrasonic waves in this embodiment, the specific preparation steps are as follows:

[0044] (1) Pretreatment of amino acid ionic liquid: uniformly mix crushed 50-mesh corn stalk and lysine amino acid ionic liquid at 70° C. in a mass ratio of 3%, and obtain the mixture after 2.0 hours of treatment;

[0045] (2) Ultrasonic treatment: the solid-liquid mixture obtained in step (1) was placed in an ultrasonic water bath for ultrasonic treatment for 30 minutes at an ultrasonic power of 100W, and the temperature was controlled at 25°C;

[0046] (3) Post-treatment: centrifuge the mixture obtained in step (2) at 5000 rpm for 10 min; finally freeze-dry at -50° C. for 12 hours to obtain solid nanocellulose.

[0047] The performance index of the nanocellulose prepared in this example: yield: 36.42%; diameter: 48-209 nm; length: 163-981 nm, crystallinity: 81.79%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com