Diesel engine lubricant composition and preparation method and application thereof

A lubricating oil composition and diesel engine technology, applied in lubricating compositions, petroleum industry, organic chemistry, etc., can solve problems such as low emissions, clogged oil filters, cylinder liner piston rings, friction pair wear of valve groups, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

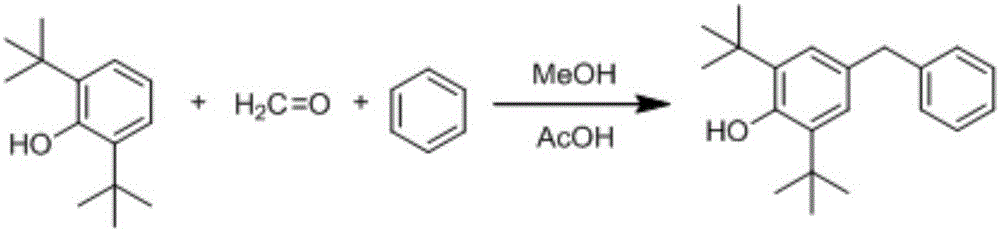

[0091] In a 500ml flask with an electromagnetic stirrer (stirring speed: 200rpm), fill with nitrogen protection, add 150ml of methanol and 0.01mol of acetic acid, fully cool in an ice-water bath, and then add 0.1mol of 2,6-di tert-butylphenol, 0.2 mol of formaldehyde and 0.3 mol of benzene. After reacting for 1 hour, remove the ice-water bath, heat up to 25°C, heat to 75°C and continue to reflux for 2 hours, then stop the reaction, evaporate the solvent from the reacted system at 0.03MPa and 50°C, then add 250ml of ethyl acetate, and Transfer to a separatory funnel, wash with 100ml of distilled water (twice) and 50ml of saturated brine, and add 10g of anhydrous calcium chloride to dry at 25°C for 20min, and evaporate the filtered filtrate at 40°C and 0.03MPa solvent to obtain the intermediate product M1.

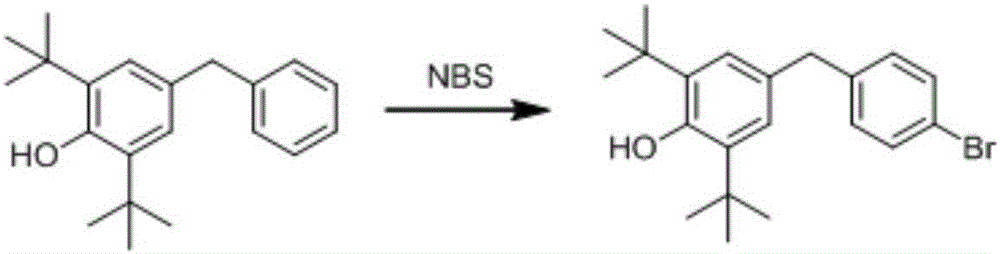

[0092] In a 500ml flask with an electromagnetic stirrer (stirring speed is 200rpm), fill with nitrogen protection, add 150ml of dry tetrahydrofuran, then dissolve the inter...

Embodiment 10-12

[0118] Examples 10-12 and Comparative Examples 10-12.

Embodiment 10

[0119] Examples 10-13 are the composition of the diesel engine lubricating oil of the present invention. Each component was prepared to obtain a CH-4 diesel engine lubricating oil composition (Example 10 and Example 11) and a CI-4 diesel engine lubricating oil composition (Example 12) with a viscosity grade of 15W-40.

[0120] Examples 10-12 and Comparative Examples 10-12 have the same formula composition except for the dispersant, and their respective composition ratios are shown in Table 6, and the results of the carbon black dispersion test are shown in Table 7.

[0121] Table 6

[0122]

[0123] Table 7

[0124] oil sample Carbon black dispersion test viscosity growth rate / % Example 10 65 Example 11 63 Example 12 50 Comparative example 10 81 Comparative example 11 79 Comparative example 12 69

[0125] As can be seen from Table 6 and Table 7, in the case of the same combination of anti-oxidation type ashless dispersan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com