Cefotaxime sodium compound prepared by fluid mechanics principle and preparation of cefotaxime sodium compound

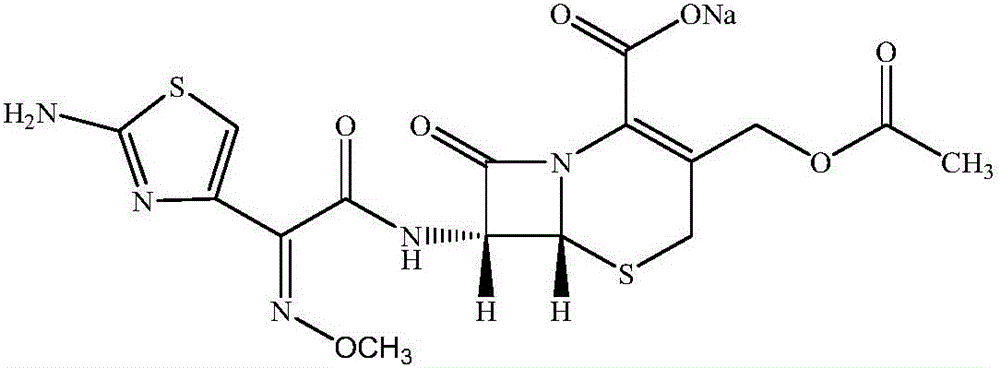

A technology of cefotaxime sodium and its compound, which is applied in the field of cefotaxime sodium compound and its preparations, and can solve problems such as poor crystallization state, high impurity and instability of cefotaxime sodium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

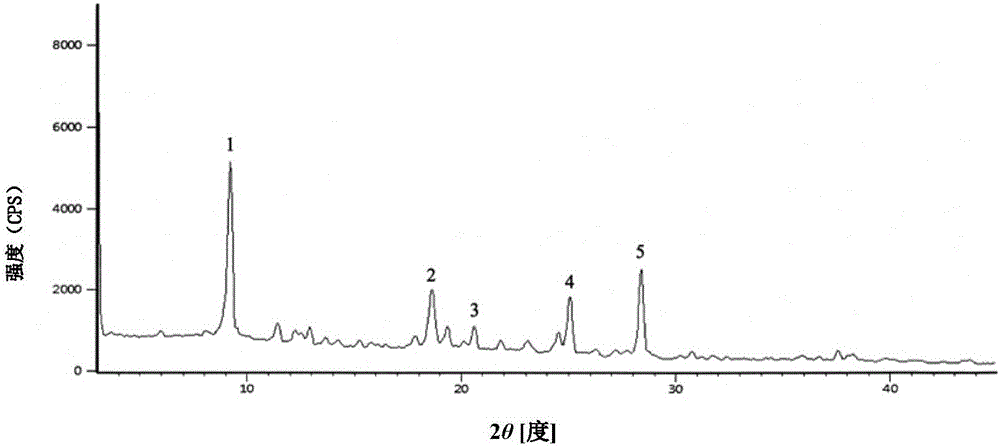

Image

Examples

Embodiment 1

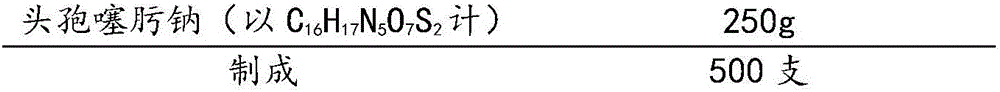

[0030] Embodiment 1: the preparation of cefotaxime sodium

[0031] Measure 500ml of ethyl acetate and 100ml of water and add them to the standing wave reactor of the hydrodynamic principle device. The temperature of the water bath is 100°C. Stir and mix well. , slowly add 50.34g of sodium carbonate, adjust the pH value to 4.2, after the pH value is stable, add 0.85g of activated carbon for decolorization for 30min, and filter. Wash the carbon cake successively with acetone 50ml×2 and water 50ml×2. The temperature of the solvent circulation tank is controlled at 18-20°C, the temperature of the standing wave reactor is controlled at 30-35°C, the circulation pump is turned on, and 300ml of ethyl acetone (ratio 1:5) mixture is added dropwise to the standing wave reactor, and the Then continue to circulate for 5 minutes, turn off the circulation pump, and let stand for crystallization for 30 minutes. Slowly lower the temperature of the solvent circulation tank to 5-8°C, turn on t...

Embodiment 2

[0038] Embodiment 2: the preparation of cefotaxime sodium

[0039] Measure 600ml of ethyl acetate and 100ml of water and add them to the standing wave reactor of the hydrodynamic principle device. The temperature of the water bath is 80°C. Stir and mix well. , slowly add 50.50 g of sodium carbonate, adjust the pH value to 5.0, after the pH value is stable, add 0.90 g of activated carbon for decolorization for 30 min, and filter. Wash the carbon cake successively with acetone 50ml×2 and water 50ml×2. The temperature of the solvent circulation tank is controlled at 15-18°C, the temperature of the standing wave reactor is controlled at 30-35°C, the circulation pump is turned on, and 400ml of ethyl acetone (ratio 1:4) mixture is added dropwise to the standing wave reactor. Then continue to circulate for 5 minutes, turn off the circulation pump, and let stand for crystallization for 30 minutes. Slowly lower the temperature of the solvent circulation tank to 6-10°C, turn on the ci...

Embodiment 3

[0040] Embodiment 3: the preparation of cefotaxime sodium

[0041]Measure 400ml of ethyl acetate and 100ml of water and add them to the standing wave reactor of the hydrodynamic principle device. The temperature of the water bath is 105°C. Stir and mix well. , slowly add 50.42g of sodium carbonate, adjust the pH value to 5.5, after the pH value is stable, add 0.84g of activated carbon for decolorization for 30min, and filter. Wash the carbon cake successively with acetone 50ml×2 and water 50ml×2. The temperature of the solvent circulation tank is controlled at 10-16°C, the temperature of the standing wave reactor is controlled at 30-35°C, the circulation pump is turned on, and 400ml of ethyl acetone (ratio 1:4) mixture is added dropwise to the standing wave reactor. Then continue to circulate for 5 minutes, turn off the circulation pump, and let stand for crystallization for 30 minutes. Slowly lower the temperature of the solvent circulation tank to 5-8°C, turn on the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com