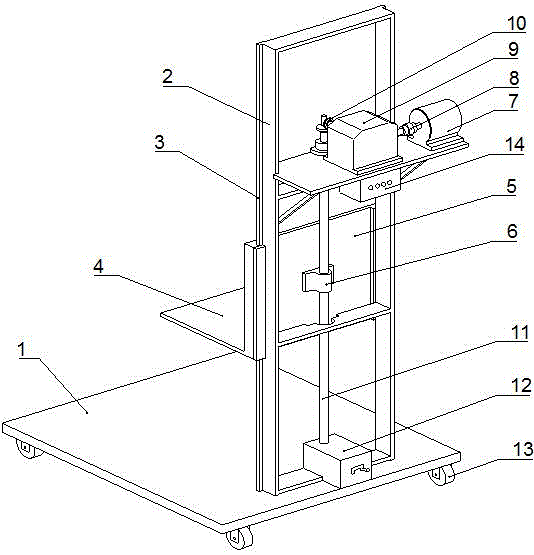

Movable elevating device

A lifting device and lifting component technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of consuming a lot of time and labor, affecting production capacity and labor intensity, heavy parts and components, etc., achieving low manufacturing and maintenance costs, reducing electrical Automation components, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In the process of processing large-diameter gears such as sugarcane pressing or mining machinery, the inventor often consumes too much manpower and time due to the movement and clamping of large-scale gear blanks. Although the original mobile crane can quickly move and lift the gear blank, because the mechanical cutter head and motor and other mechanisms are installed above the workbench, when the mobile crane travels close to the workbench, its hook and wire often collide with the top parts of the equipment. There is no small hidden danger to the safety of the equipment.

[0030] In February 2016, the movable lifting device of the present invention was adopted, and according to its production requirements, the shape of the support plate 4 was appropriately improved, so that the support plate 4 and the processing table form butt teeth, which facilitates placing the gear on the work table. The working process of the device is as follows: move the lifting device to the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com