Encapsulation method for integral molding of stringer panel structure

A technology of integral molding and packaging method, which is applied in the field of resin matrix composite material molding, and can solve the problems of inability to realize packaging and cavity packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

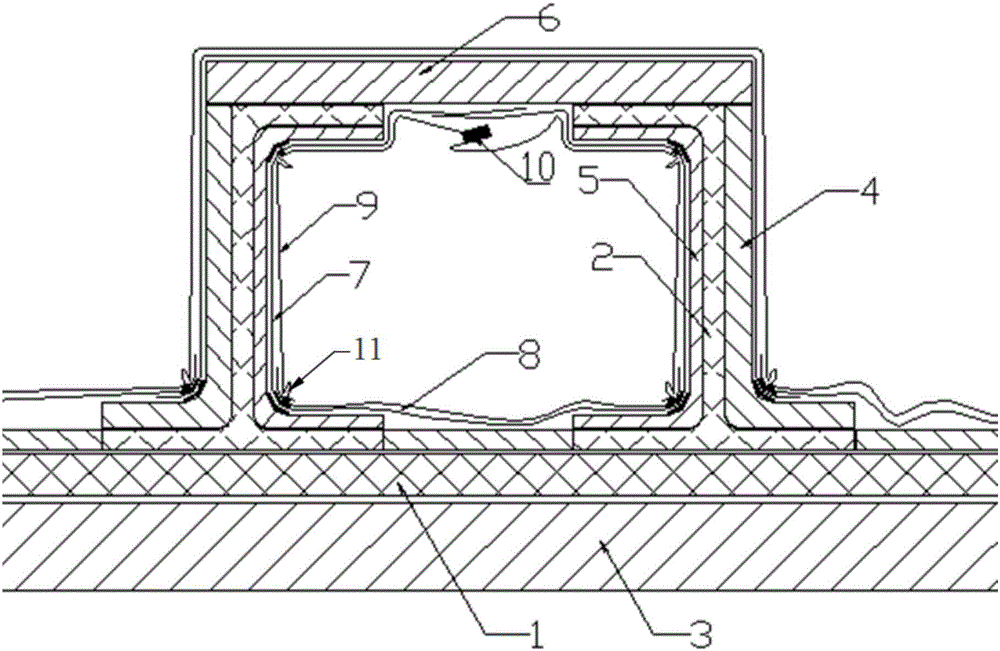

[0036] by figure 1 The wall plate with two "J"-shaped cross-section long stringers is shown as an example. In order to ensure the surface accuracy of the upper flange of the long stringer, the outer surface of the upper flange of the stringer adopts a rigid upper flange shape mold, and the two long stringers The girders share one upper flange shape mold, and after assembling the upper flange shape mold, a closed cavity is formed between the girders. This structure cannot be packaged after the upper flange shape mold is assembled.

[0037] In order to solve the problem of forming and encapsulating such integral wall panels, this technical solution is adopted. Before assembling the shape mold of the upper flange of the girders, pre-position the auxiliary materials and the vacuum film in the corner area of the cavity between the girders where the bridge is easy to be bridged so that they can be attached to the mold, so as to solve the problem that the upper flange shape mold of...

Embodiment 2

[0049] image 3 The integral wall plate with 4 long stringers shown in the figure, in order to ensure the surface accuracy of the upper flange of the stringer, the outer surface of the upper flange of the stringer adopts a rigid upper flange shape mold, and every two stringers share one upper flange The specific method of encapsulating the structure of the edge shape mold is as follows:

[0050] (a) Prepare the side auxiliary material 7 on the inside of the stringer cavity, the auxiliary material 8 on the inside bottom according to the distance between the lower corners of the mold 5 on the inside of the stringer, and the width of one side is 5-20 mm, and the width direction of the auxiliary material 7 on the side is according to the mold on the inside of the stringer 5 Follow the shape, the lower side is 5-20mm wider than the lower corner of the inner mold 5 of the truss, and the other side is required to be lapped at the upper part, and the lap width is at least 10mm.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com