A bar processing equipment

A technology for processing equipment and bars, which is applied in the manufacture of wood processing appliances, manufacturing tools, and wooden bars, etc. It can solve the problem of impossible to achieve right-angle V-shaped grooves, and achieve less power loss, less shear force, and less cutting. effect of margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

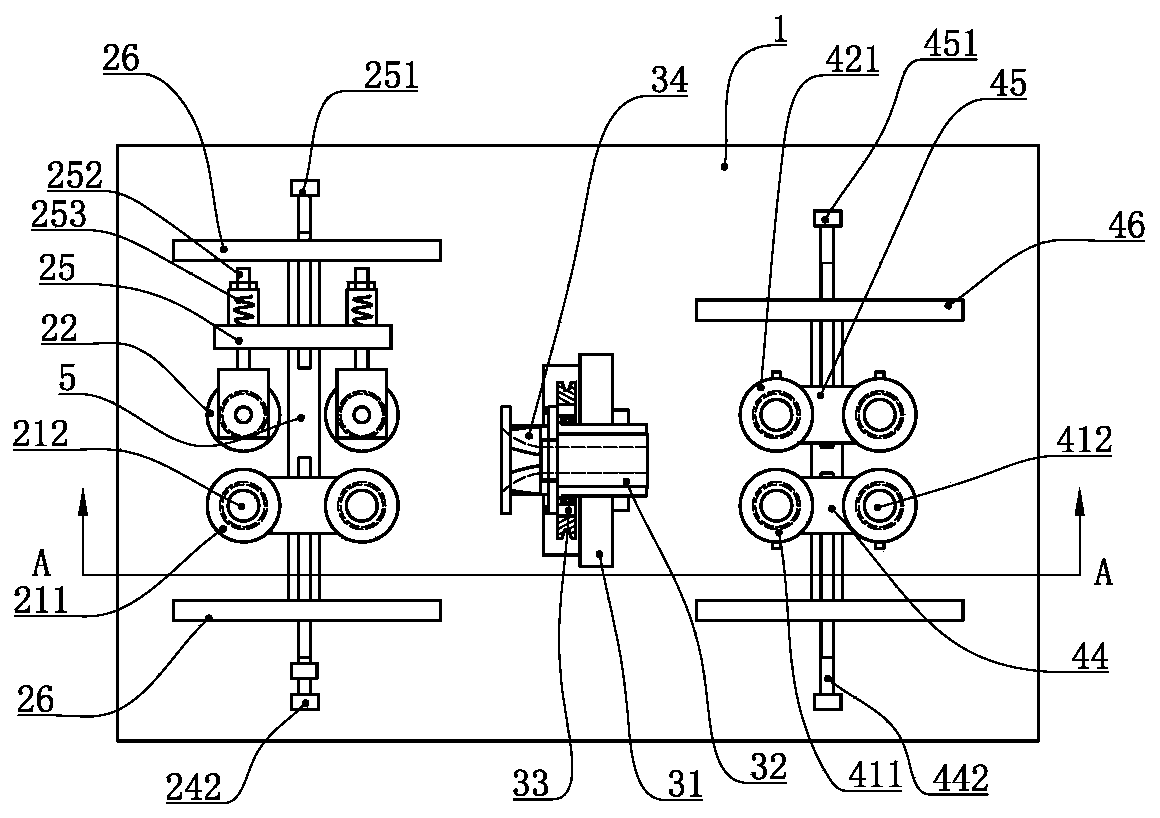

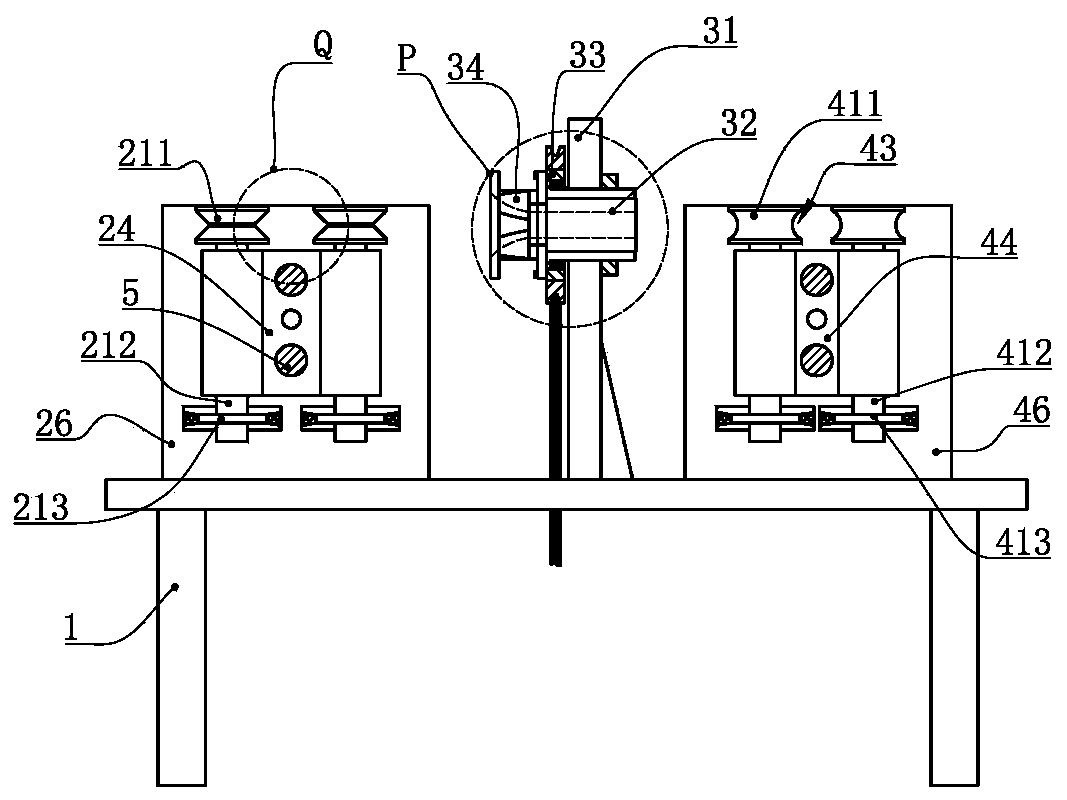

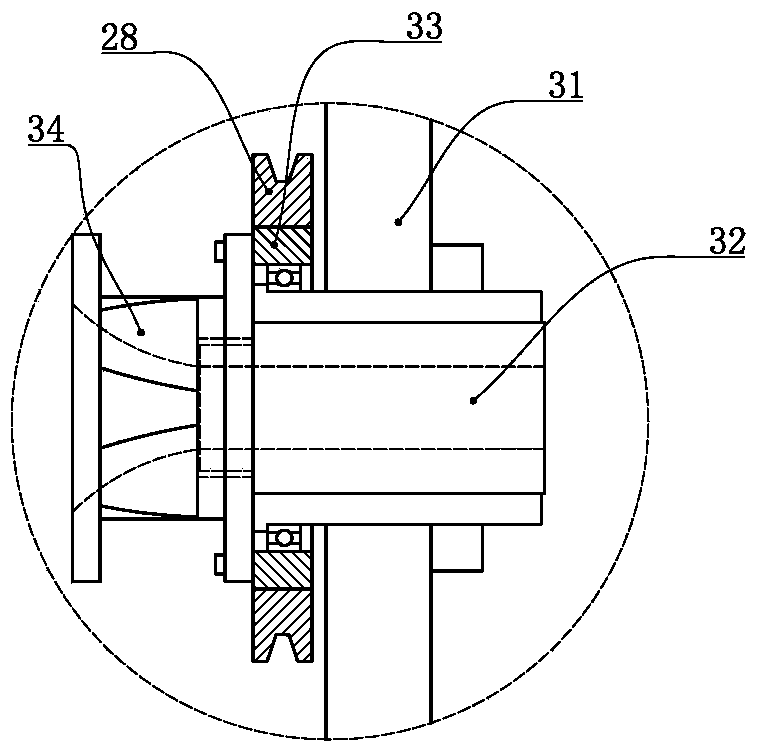

[0038] The structure of the rod processing equipment of the present invention will be further described below in conjunction with the accompanying drawings.

[0039] Refer to attached Figure 1-9 , each functional part of the bar processing equipment described in the present invention is in a straight line from the front end to the rear end, and the feeding mechanism, the milling mechanism, and the discharging mechanism are sequentially arranged on the frame 1 from the back to the front.

[0040] The left and right sides of the feed mechanism are respectively provided with a feed mechanism installation riser 26, the feed mechanism installation riser 26 is fixed with the frame 1, and the left and right ends of the upper and lower two parallel slide rails 5 are respectively fixed on the feed mechanism installation riser 26 on both sides. , two parallel slide rails 5 slidingly assemble the active feeding bearing seat 24 and the driven feeding roller mounting seat plate 25, the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com