Online repairing method and tool for ring rolling mill abrasion roller

A repair method and tooling technology are applied in the field of online repair of various worn rolls of ring rolling mills, which can solve problems such as affecting the continuous production, and achieve the effects of improving the operating rate of equipment and reducing the time for replacing rolls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further describe the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

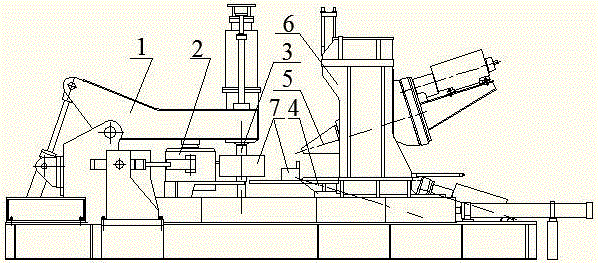

[0011] As shown in the figure, an online repair method and tooling for worn rolls of a ring rolling mill, including an online repair method and tooling for worn main rolls and an online repair method and tooling for worn cone rolls, is characterized in that: the wear The online repair method and tooling of the main roller are based on the fact that the wear of the main roller 2 is mainly the wear of the cylindrical surface of the main roller 2. As long as the worn surface is processed, the online repair of the main roller 2 can be realized, and the main roller 2 itself can be used. Rotational movement is the cutting speed, and the linear movement of the core roller frame 1 is the cutting depth. At the same time, designing suitable fixtures and controlling the feed speed can complete the processing of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com