Intelligent transmission laser cutting machine

A laser cutting machine, intelligent technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the laser cutting machine cannot automatically feed, adjust and control the position of materials, etc., to achieve easy promotion, improve overall performance, and structure Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

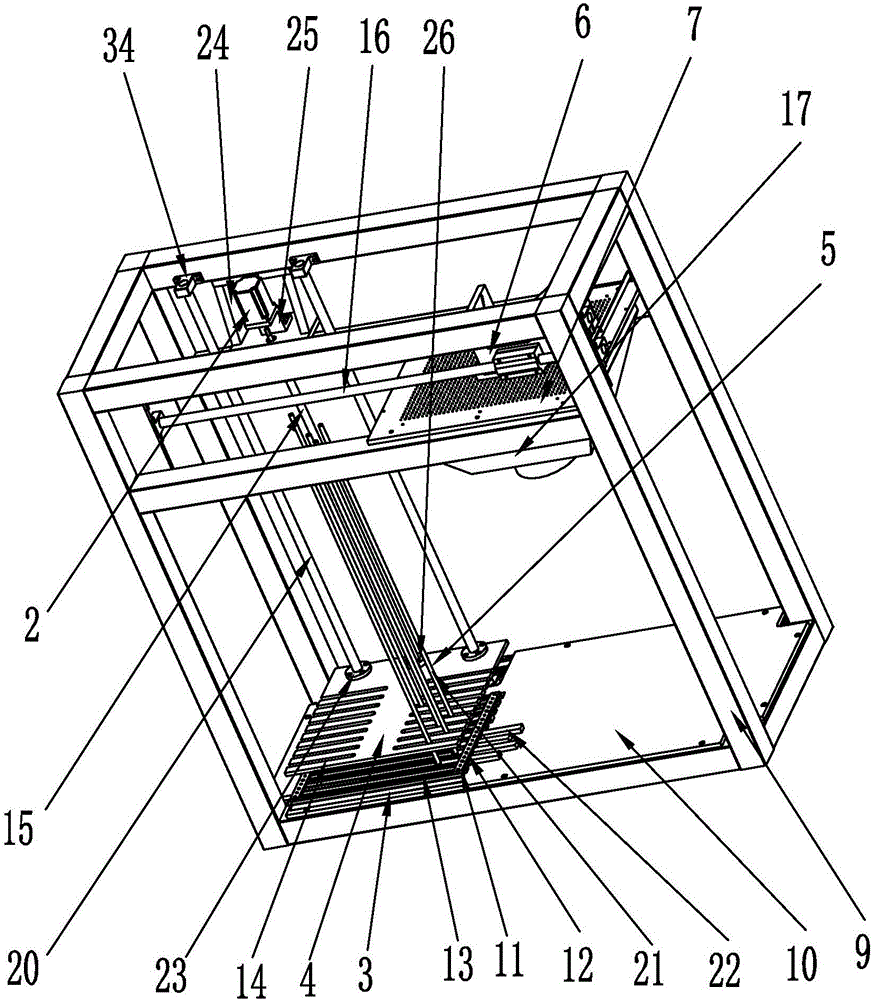

[0015] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0016] like Figure 1 to Figure 7 As shown, an intelligent transmission laser cutting machine includes a sheet metal cover 1, a material lifting motor 2, a groove plate 3, a material lifting platform 4, an adjustment roller 5, a material transmission device 6 and a working platform 7, and the sheet metal The outer cover 1 is provided with two left and right symmetrical outer cover doors 8 and a controller. The sheet metal outer cover 1 is provided with a fixed bracket 9 and a bottom plate 10 fixedly connected by bolts. Grooved plate 3, bead 11 is provided with installation hole 12, and grooved plate 3 is provided with evenly distributed groove structure 13, and the top of grooved plate 3 is provided with the lifting platform 4 that cooperates with grooved plate 3, lifts The adjustment gap 14 corresponding to the groove structure 13 is arranged on the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com