Shearing stroke control method for plate shearing machine based on plate width

A control method and shearing machine technology, applied in the direction of program control, computer control, shearing machine control device, etc., can solve the problems of affecting shearing efficiency, shearing accuracy cannot be guaranteed, and increase maintenance cost of machine tool manufacturers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The method of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

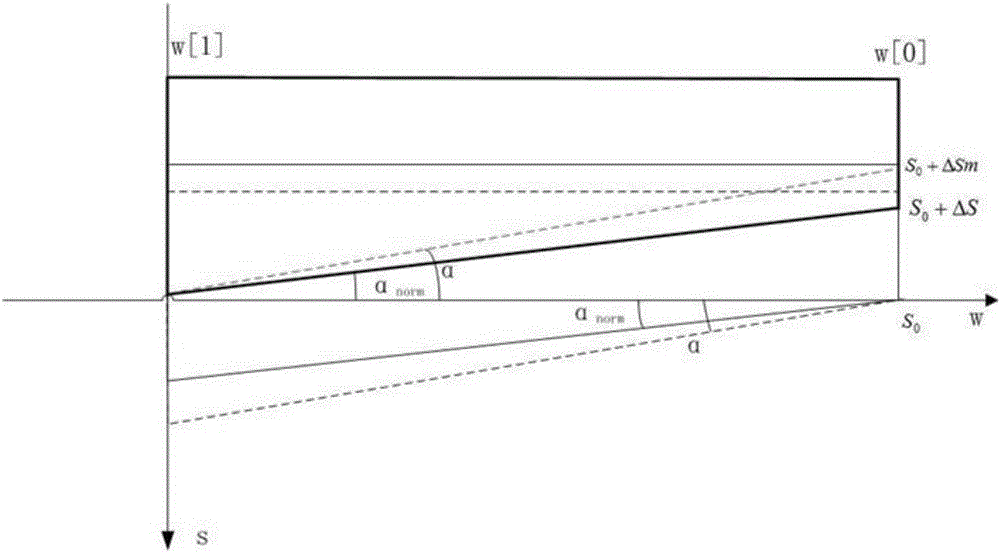

[0086] First determine the maximum shear angle and minimum shear angle of the machine tool, set the shear angle range to 0.5°-2.0°, and select the calibration angle α norm = 1.2°.

[0087] It is known that the maximum shear distance of the machine tool is 3200mm. Adjust the shearing angle of the knife post to 1.2°, perform the shearing action, and record the feedback voltage value when the shearing plate width is 0mm and the feedback voltage value when the shearing plate width is 3200mm. Enter the data into the shear voltage parameter table, as shown in Table 2.

[0088] Table 2 Parameter table under calibration angle

[0089] Shear plate width(mm) Voltage value (V) 3200 4 0 8

[0090] Set target clipboard width W target It is 2000mm, and the shearing action is performed. After measurement, it is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com