Polymer electrolyte membrane based on sodium glycinate and preparation method and application of membrane

A technology of sodium glycinate and polyelectrolyte, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of difficulty in achieving simultaneous improvement of permeability and selectivity, restriction of separation performance, etc., so as to improve gas separation performance, The effect of low price and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

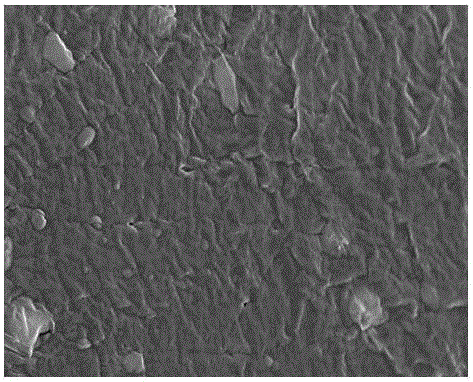

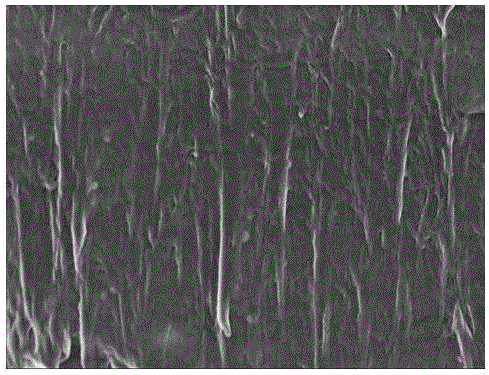

Image

Examples

Embodiment 1

[0026] Prepare a polyelectrolyte membrane based on sodium glycinate, the polyelectrolyte membrane has a thickness of 115 μm, and the polyelectrolyte membrane uses polyether-polyamide block copolymer as the membrane matrix, and sodium glycinate is added in the membrane matrix, wherein the polyether -The mass ratio of polyamide block copolymer to sodium glycinate is 1:0.05, the preparation method of this polyelectrolyte membrane is as follows:

[0027] The preparation of step 1, sodium glycinate solution:

[0028] Add 5 g of ethanol aqueous solution with a mass fraction of 70% in the sample tube, weigh 0.05 g of sodium glycinate, add it into the above sample tube, shake well until the sodium glycinate dissolves, and obtain a sodium glycinate solution;

[0029] Step 2, the preparation of polyether-polyamide block copolymer solution:

[0030] Weigh 1.0g of polyether-polyamide block copolymer and dissolve it in 19g of 70% ethanol aqueous solution by mass fraction, stir at 80°C for...

Embodiment 2

[0034] Prepare a polyelectrolyte membrane based on sodium glycinate. The difference from the polyelectrolyte membrane in Example 1 is that the thickness of the membrane is 128 μm, wherein the mass ratio of polyether-polyamide block copolymer to sodium glycinate is 1:0.1, The only difference between the preparation of the polyelectrolyte membrane and the preparation method of Example 1 is that in step 1, the weighing of 0.05 g sodium glycinate is changed to weighing 0.1 g of sodium glycinate; in step 3, a polyelectrolyte with a thickness of 128 μm is finally obtained membrane.

Embodiment 3

[0036] Prepare a polyelectrolyte membrane based on sodium glycinate. The difference from the polyelectrolyte membrane in Example 1 is that the thickness of the membrane is 143 μm, wherein the mass ratio of polyether-polyamide block copolymer to sodium glycinate is 1:0.15, The only difference between the preparation of the polyelectrolyte membrane and the preparation method of Example 1 is that in step 1, 0.05 g of sodium glycinate is changed to 0.15 g of sodium glycinate; in step 3, a polyelectrolyte with a thickness of 143 μm is finally obtained membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com