Center driving thickener

A technology of central transmission and thickener, applied in the direction of sedimentation tank, etc., can solve the problems of high failure rate and loud noise, and achieve the effect of safe and reliable operation, low noise and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

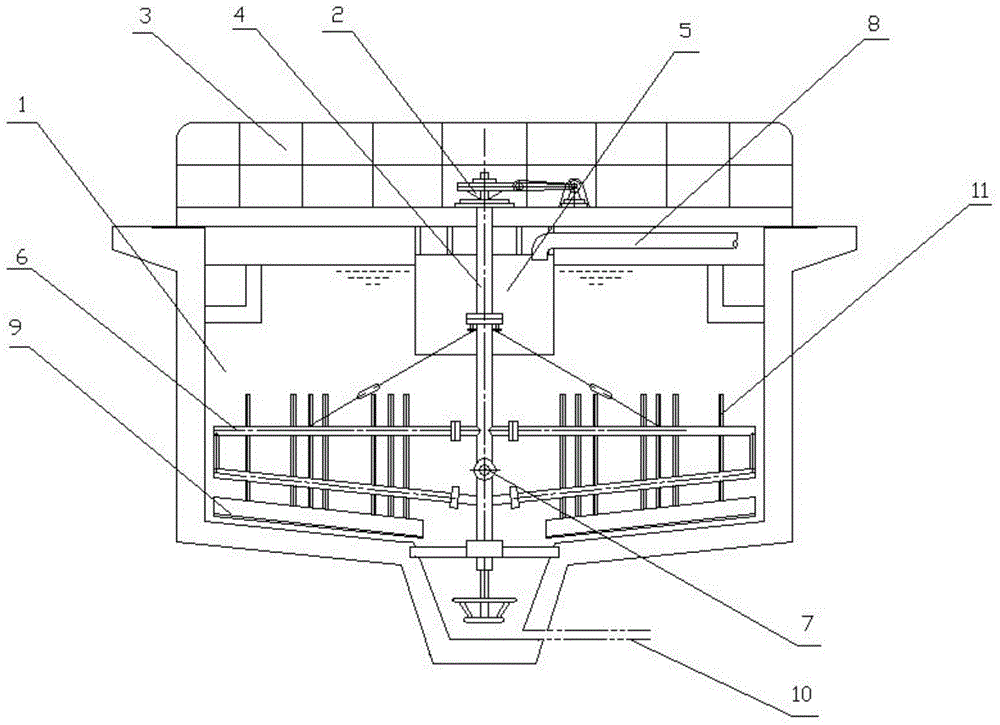

[0011] Such as figure 1 The shown central drive concentrator includes a sedimentation tank 1, a driving device 2 is arranged in the center of the sedimentation tank 1, and is fixed on a working platform 3 above the sedimentation tank 1. The driving device 2 is connected to the central main shaft 4, and the central main shaft The upper part of 4 is connected with the steady flow cylinder 5, the lower part is connected with the mud scraper frame 6, the water inlet pipe 7 communicates with the steady flow cylinder 5 through the central spindle 4, and the overflow pipe 8 is arranged on the upper end of the steady flow cylinder 5, and the mud scraper The bottom of the plate frame 6 is connected with a mud scraper 9, and a sludge discharge port 10 is arranged at the bottom of the sedimentation tank 1; in order to facilitate the accumulation of sludge, the center of the bottom of the sedimentation tank 1 is an inverted trapezoid; in order to improve the mud scraping effect , the scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com