Hole type transplanting machine

A technology of transplanting machine and frame, which is applied in the field of agricultural transplanting, can solve the problems that the angle cannot be adjusted, and achieve the effects of reducing the cost of transplanting, good quality, and simple angle adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

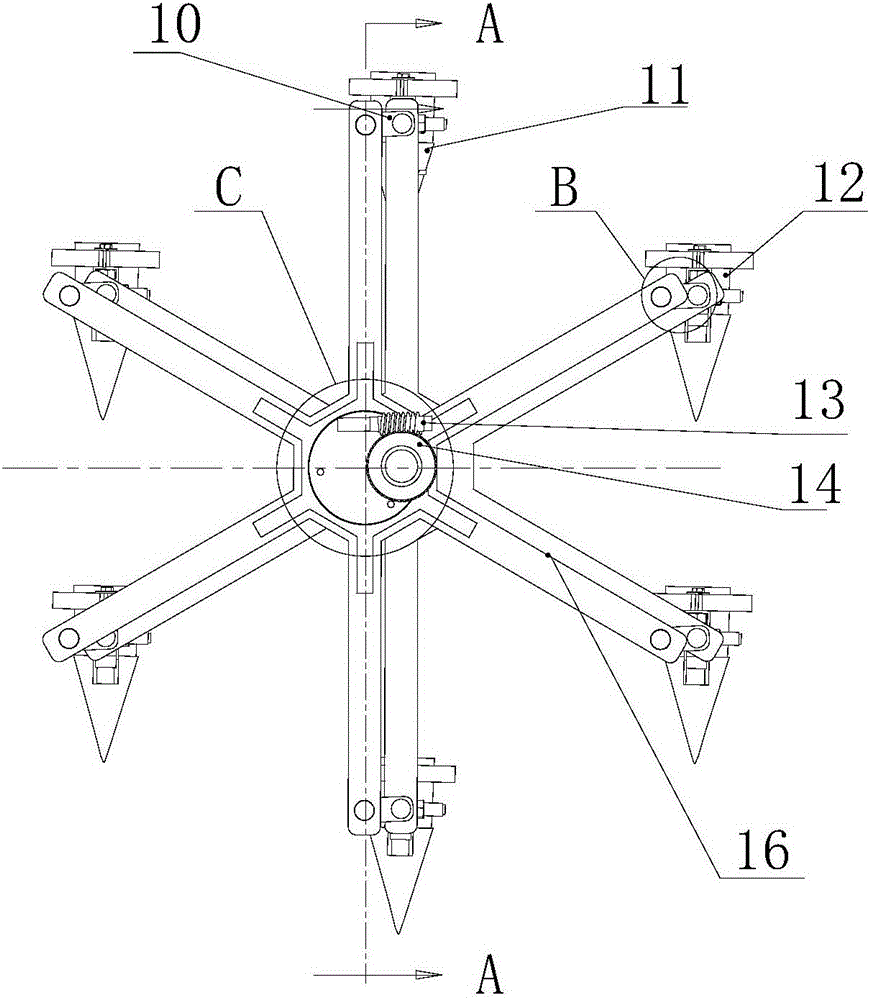

[0035] Hole type transplanting machine of the present invention such as figure 1 As mentioned above, the hole-type transplanting machine is driven by ground wheels and operated in two rows. Including frame 2, angle adjustment transplanting part, power transmission part, projecting seedling part and covering soil suppressing part, the angle adjusting transplanting part, power transmission part, projecting seedling part and covering soil suppressing part are all arranged on the frame 2. The front end of the frame 2 is provided with a traction frame 1, and the tractor positioned at the front of the transplanter is connected with the traction frame 1. When the tractor moves, it pulls the traction frame 1 to move forward, and the traction frame 1 drives the transplanter to move through the power transmission unit.

[0036] The power transmission part includes a ground wheel 7, four groups of sprockets and two groups of upper and lower bevel gears, the four groups of sprockets are a...

Embodiment 2

[0048] The difference from Example 1 is: in order to solve the problem of carrying soil when the transplanter leaves the soil, and reduce the disturbance of the transplanter to the soil, the connection between the transplanter 4 and the centering transplanting wheel is provided with a hydraulic cylinder 23. The cylinder body of the hydraulic cylinder 23 is fixed on the centering transplanting wheel, and one end of the transplanting frame connecting shaft 406 is connected with the piston rod of the hydraulic cylinder 23 while being connected with the centering transplanting wheel. The heart transplanting wheel is provided with a slideway 22, and the end of the transplanting frame connecting shaft 406 can slide up and down along the slideway 22. Its working principle is to utilize the hydraulic cylinder to take the lower part 405 of the transplanting device out of the transplanting hole quickly. Such as Figure 11 As shown, when the transplanter rotates to the state at the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com