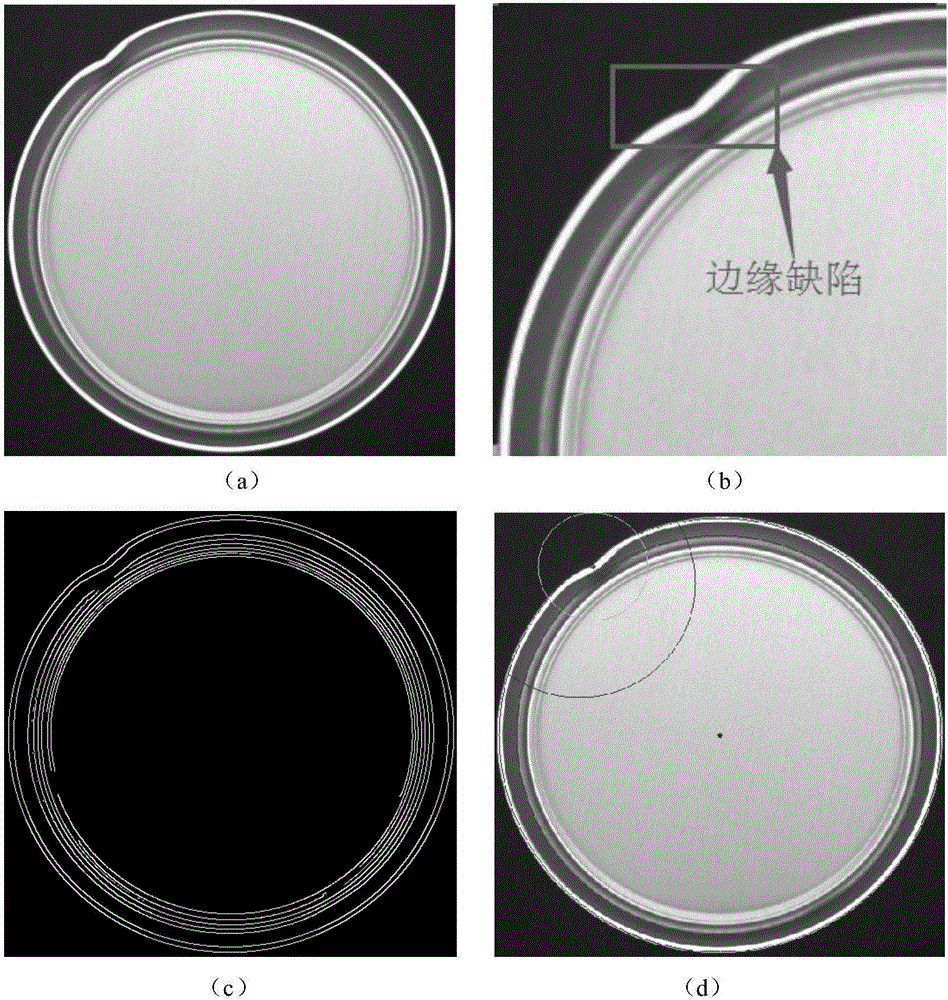

Cover defect detection method based on image processing

A defect detection and image processing technology, applied in image data processing, image analysis, image enhancement, etc., can solve problems such as high requirements for illumination consistency, prone to misjudgment and missed judgment, and prone to misdetection, and achieves a high level of improvement. The effect of detection accuracy, less detection time and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0142] Will verify effectiveness of the present invention below by embodiment.

[0143] Select a group of can lid images of the same model (model 209) containing different types of defects for defect detection processing, a total of 45 images to be detected, which contain different numbers of normal images, edge defect images, glue injection defect images, all images Both are 750×700 bmp format images. The hardware environment is Intel Core I3-2350CPU, 2.30G Hz main frequency, 4G memory, the software environment is Microsoft Windows 7 (64-bit operating system), and the VisualStudio2013 platform is used to realize the automatic detection process through C++ programming, and finally output the detection results and detection time . See Table 1 for the experimental data.

[0144] Table 1 Experimental data statistics

[0145]

[0146] It can be seen from Table 1 that the correct defect detection rate of the method of the present invention reaches 95.6%, and the detection effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com