Determination method of angle steel length of angle steel reinforced cracking box type steel column

A determination method and angle steel technology, applied in building maintenance, instrumentation, design optimization/simulation, etc., can solve the problems of lack of theoretical basis, little research on box-section steel column reinforcement design, etc., to achieve convenient construction and reduce welding residual stress , good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

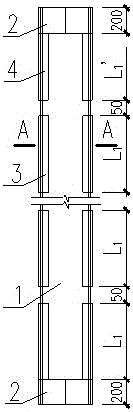

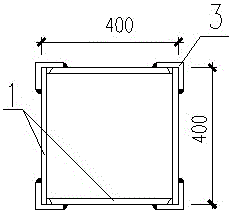

[0029] Step 1: The cracked box-shaped steel column 1 with a height of 7m and a cross-sectional size of 400×400×16 is reinforced by the method of welding angle steel 3 at four corners. In order to determine the influence of the length of the angle steel 3 on the ultimate bearing capacity of the cracked box-shaped steel column 1, Design five reinforced box-shaped steel column specimens 1 to 5 with the length of angle steel 3 as a variable and other parameters kept constant. The dimensions of the test pieces are shown in Table 1;

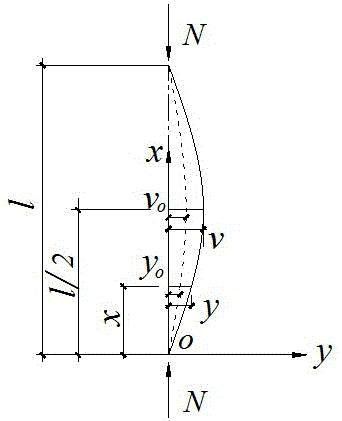

[0030] Step 2: Use the finite element software ABAQUS to conduct eigenvalue buckling analysis on the box-shaped steel column 1 specimen in the intact state to obtain the distribution characteristics of the initial bending; then use the displacement-controlled arc length method (Riks method) to consider the material The effects of nonlinearity, geometric nonlinearity, and initial bending, among which, the initial bending v 0 is 1‰ of the length l of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com