Cast-in-place gentle-gradient spatial curved roof formwork system and construction method thereof

A formwork system and gentle slope technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of poor reusability and high cost, so as to improve the turnover rate of materials and the number of turnovers , The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

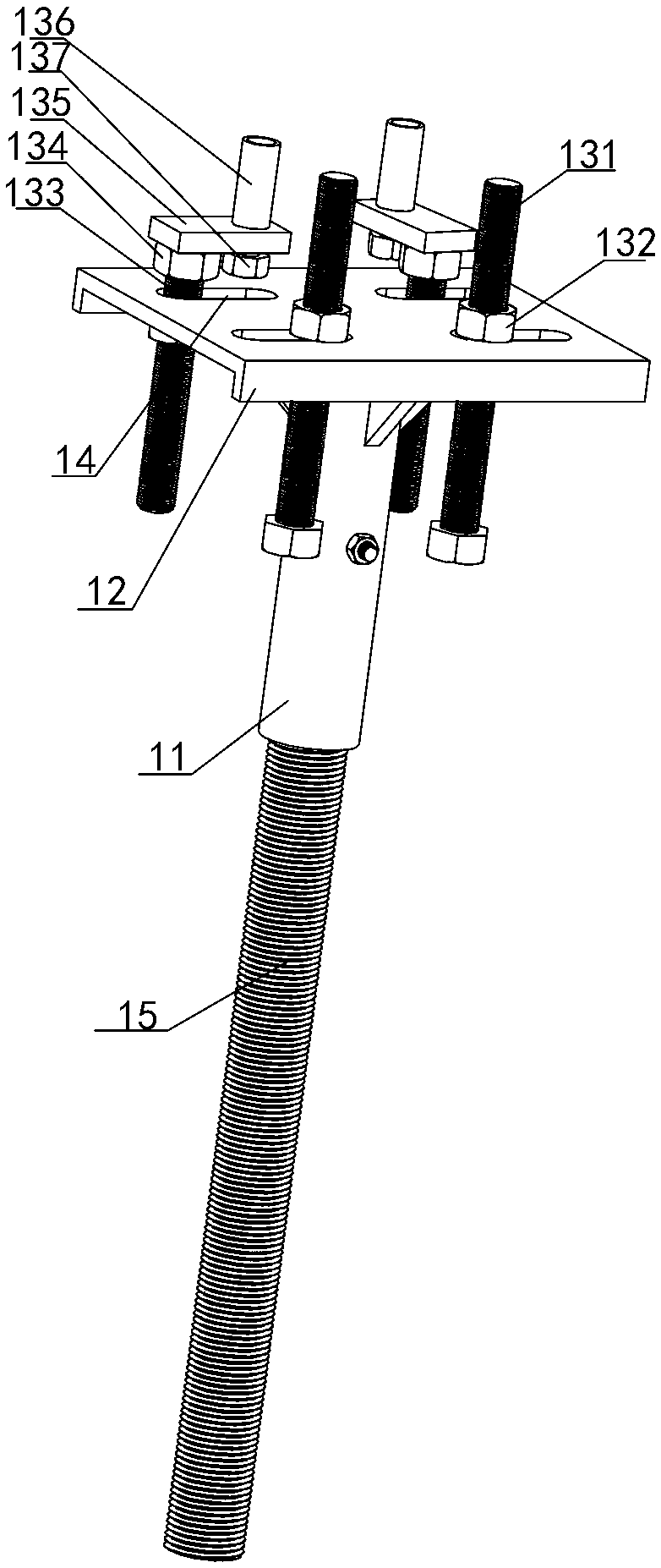

[0050] Examples see Figure 1-7 As shown, a kind of cast-in-place gentle slope space curved roof formwork system includes a bottom support structure and a surface panel structure fixedly connected to the top of the support structure. A group of vertical bars 32, a group of horizontal bars 33 and a group of inclined bars 34 are connected to each other to form, and the support structure also includes a group of height-adjustable jacking connection assemblies 1, and the number of the jacking connection assemblies is the same as that of the vertical bars. 32 have the same number and are fixedly connected to the top of the vertical bar 32 . The full hall scaffolding is a buckle-type scaffolding.

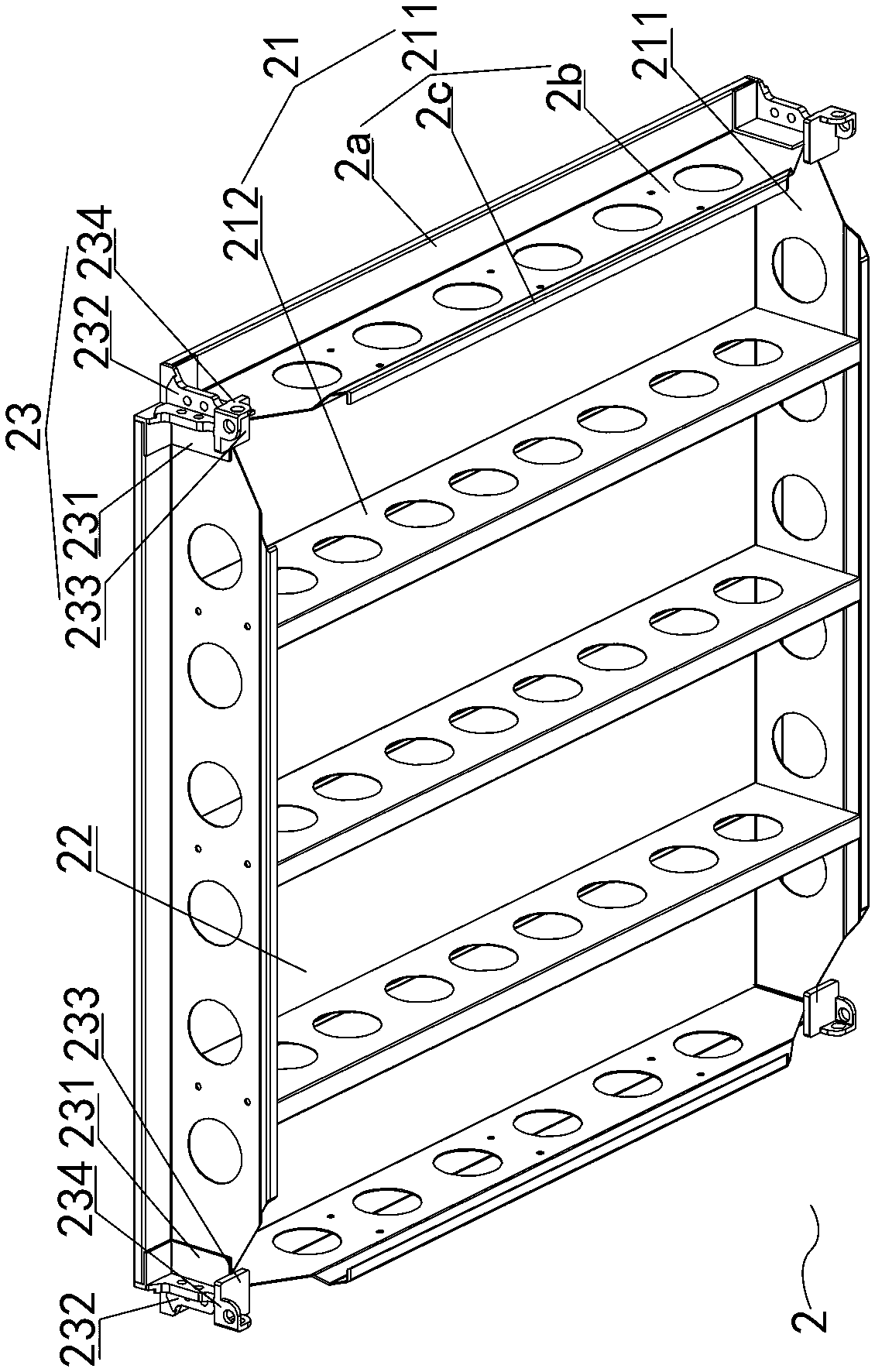

[0051] see figure 2 As shown, the panel structure is divided into a group of rectangular unit modules, and each unit module 2 includes a formwork keel 21 , a formwork panel 22 and a formwork connection assembly 23 .

[0052] The formwork keel 21 is a metal keel, and the formwork keel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com