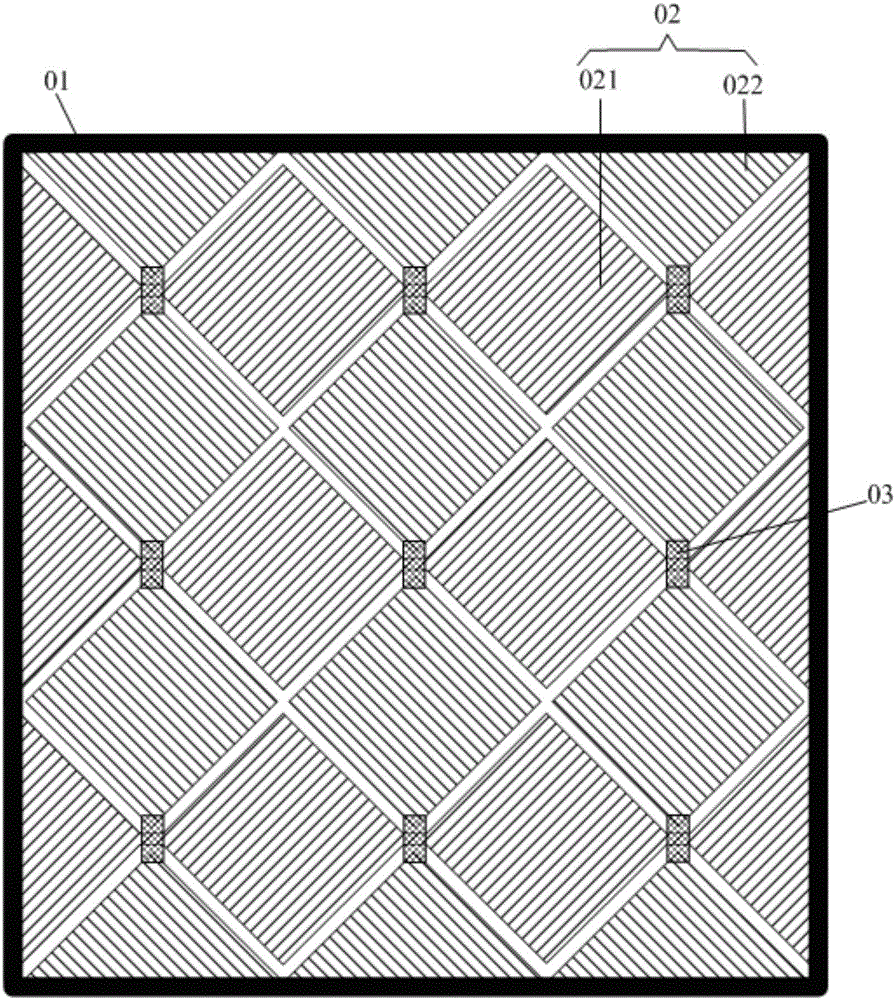

Touch screen, manufacture method thereof, and display apparatus

A manufacturing method and touch screen technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problems affecting the display quality of the touch screen, molybdenum oxide residue, etc., so as to avoid etching residues and reduce reflectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

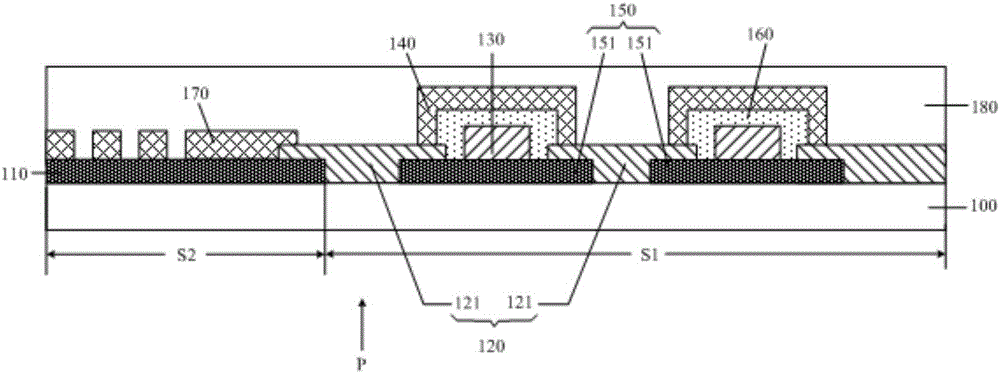

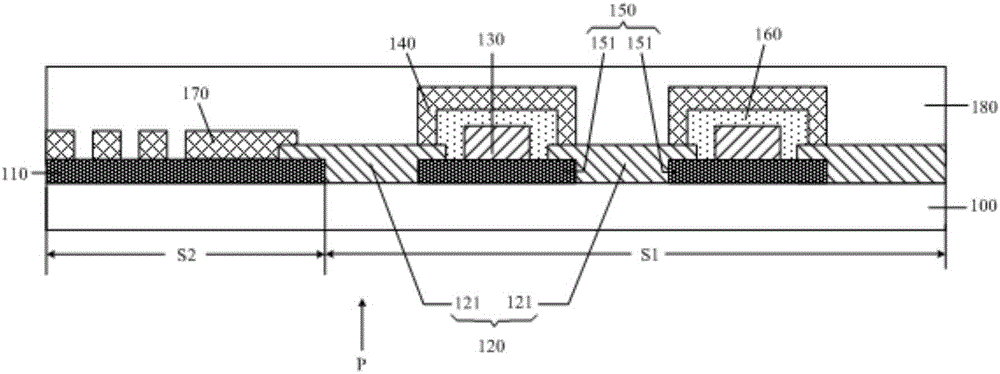

[0064] specifically, Figure 2a The manufacturing process of the touch screen shown may include the following steps:

[0065] (1) A patterning process is used to form the black matrix layer 110 and the pattern of the bottom 150 respectively on the base substrate 100; wherein, the black matrix layer 110 is located in the peripheral area S2, and the bottom 150 is located in the display area S1; as Figure 4a shown. In this way, it is not necessary to add an additional process for preparing the bottom layer 150, and only need to deform the original composition pattern for forming the black matrix layer 110 to simultaneously form the graphics of the black matrix layer 110 and the bottom layer 150, which can simplify the preparation process. Save production costs and improve production efficiency.

[0066] (2) Form the pattern of each first electrode 120 and each second electrode 130 on the base substrate 100 formed with the black matrix layer 110 and the bottom 150; wherein, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com