Multi-scale heat transport synchronous monitoring test system and test method

A test system, multi-scale technology, applied in the direction of material thermal conductivity, measuring device, particle and settlement analysis, etc., can solve the problem of boundary condition control, etc., achieve the effect of controllable inclination angle, strong contrast, and avoid human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

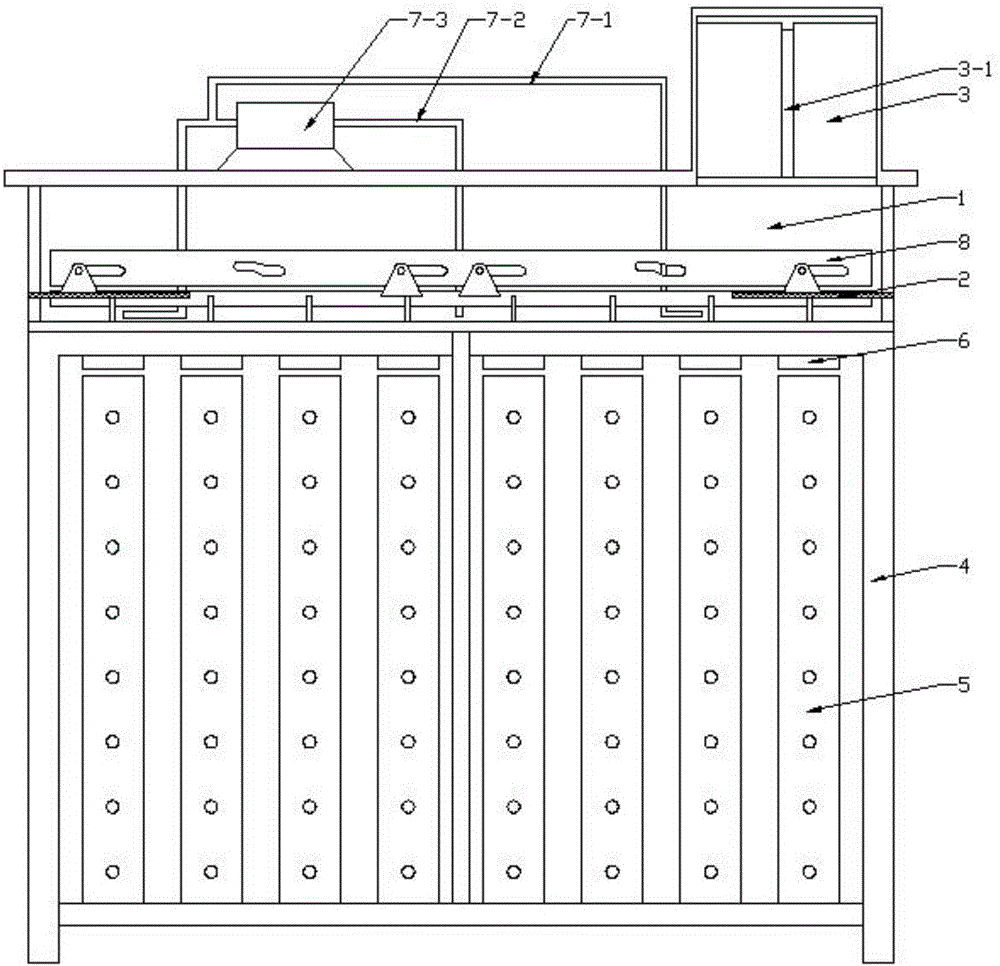

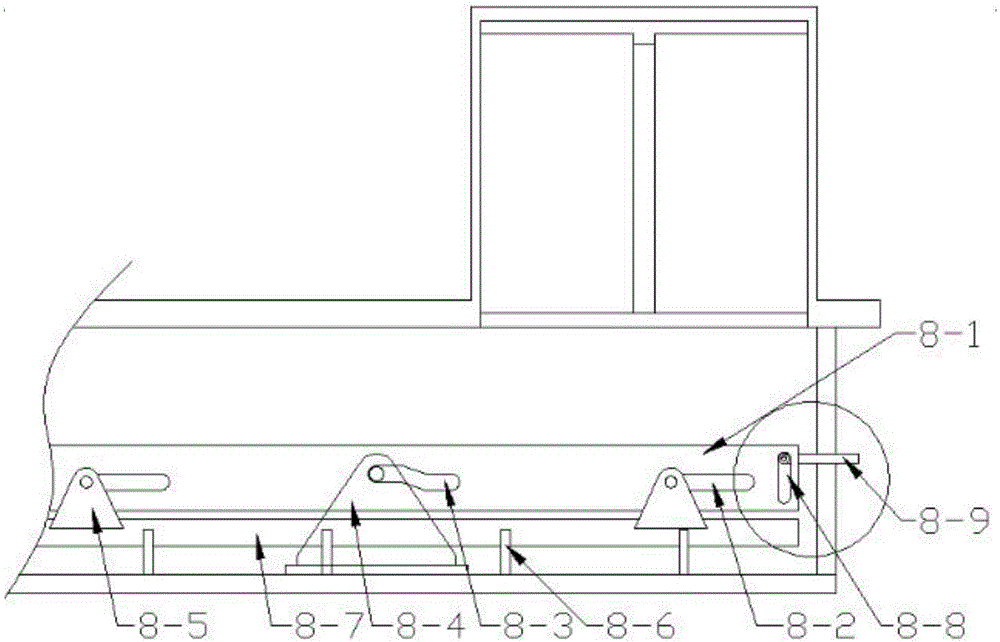

[0046] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

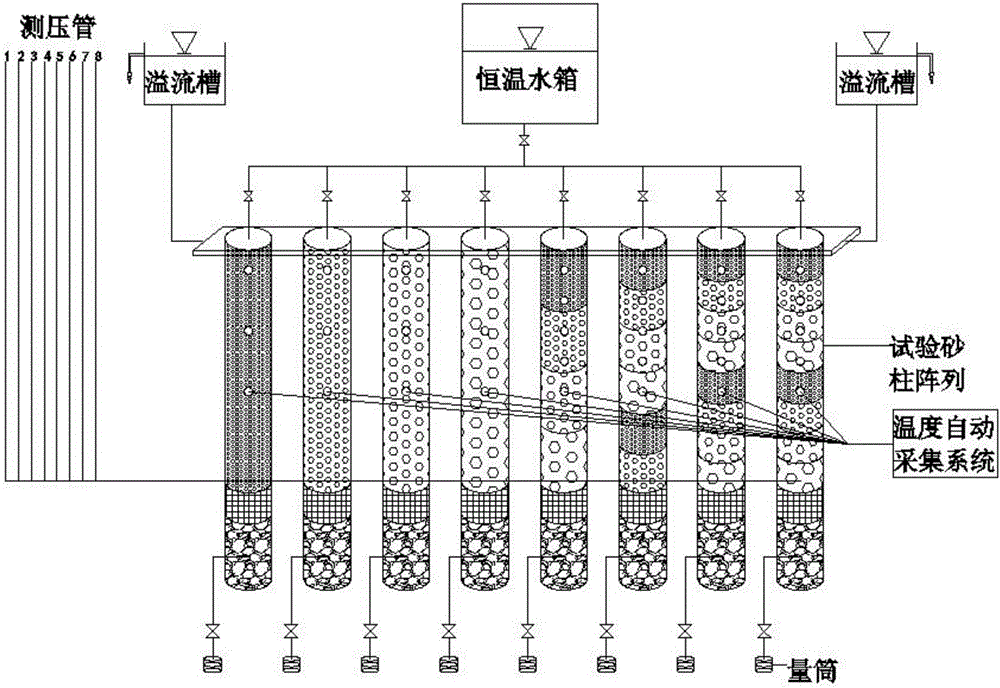

[0047] like figure 1 and figure 2 As shown, the present invention is a test device for seepage, heat conduction and convection dispersion, which mainly includes a constant temperature water tank, a test sand column array and a series of test components, wherein the constant temperature water tank and the test sand column array are all installed on a bracket Above, the constant temperature water tank is located on the top of the test sand column, and it is connected by several instantaneous diversion valves;

[0048] like figure 1 , wherein the constant temperature water tank is a transparent water tank made of acrylic material, the diversion valve is locat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filling thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com