A dynamic prediction method of rolling bearing life based on multi-feature and phase space

A rolling bearing and dynamic prediction technology, which is applied in the testing of mechanical components, the testing of machine/structural components, measuring devices, etc., can solve the problem of large errors in prediction results, cannot effectively reflect the effect of multiple factors of rolling bearings, and cannot realize the life of rolling bearings. Accurate and dynamic forecasting and other issues to reduce forecasting errors and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

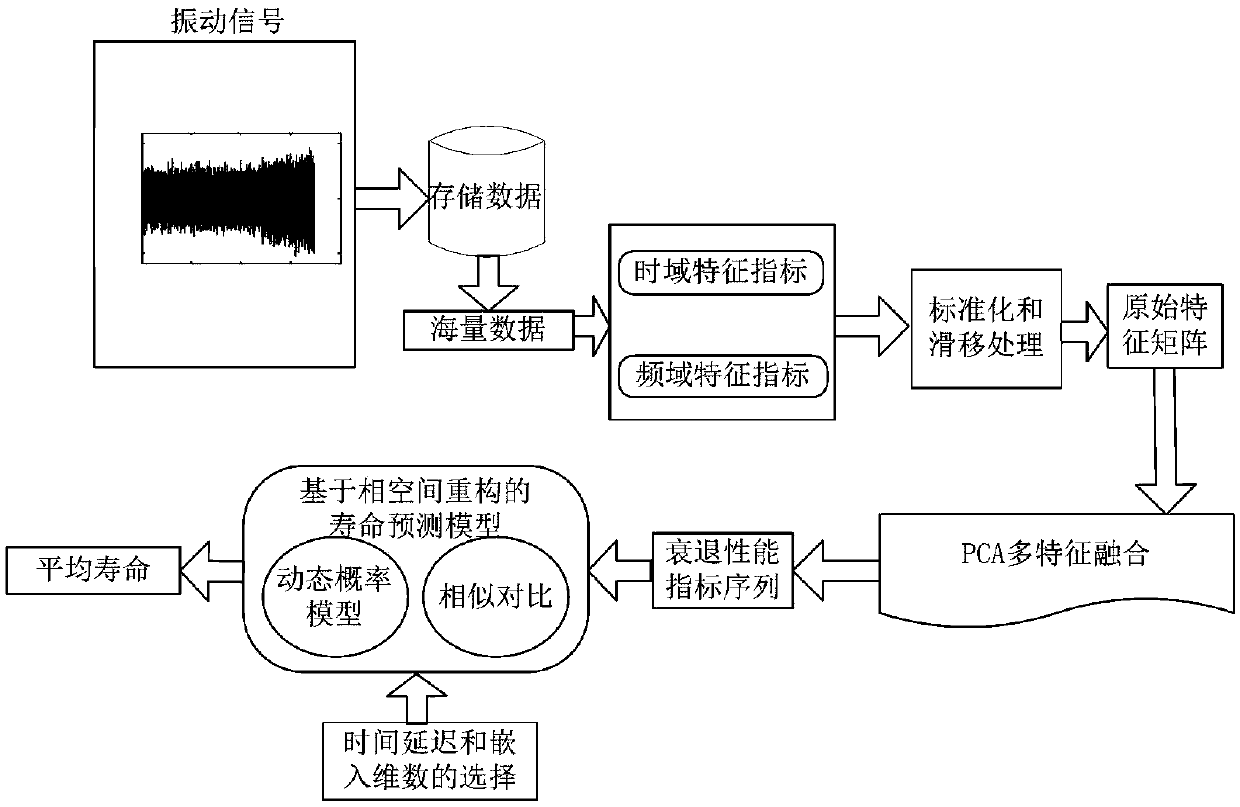

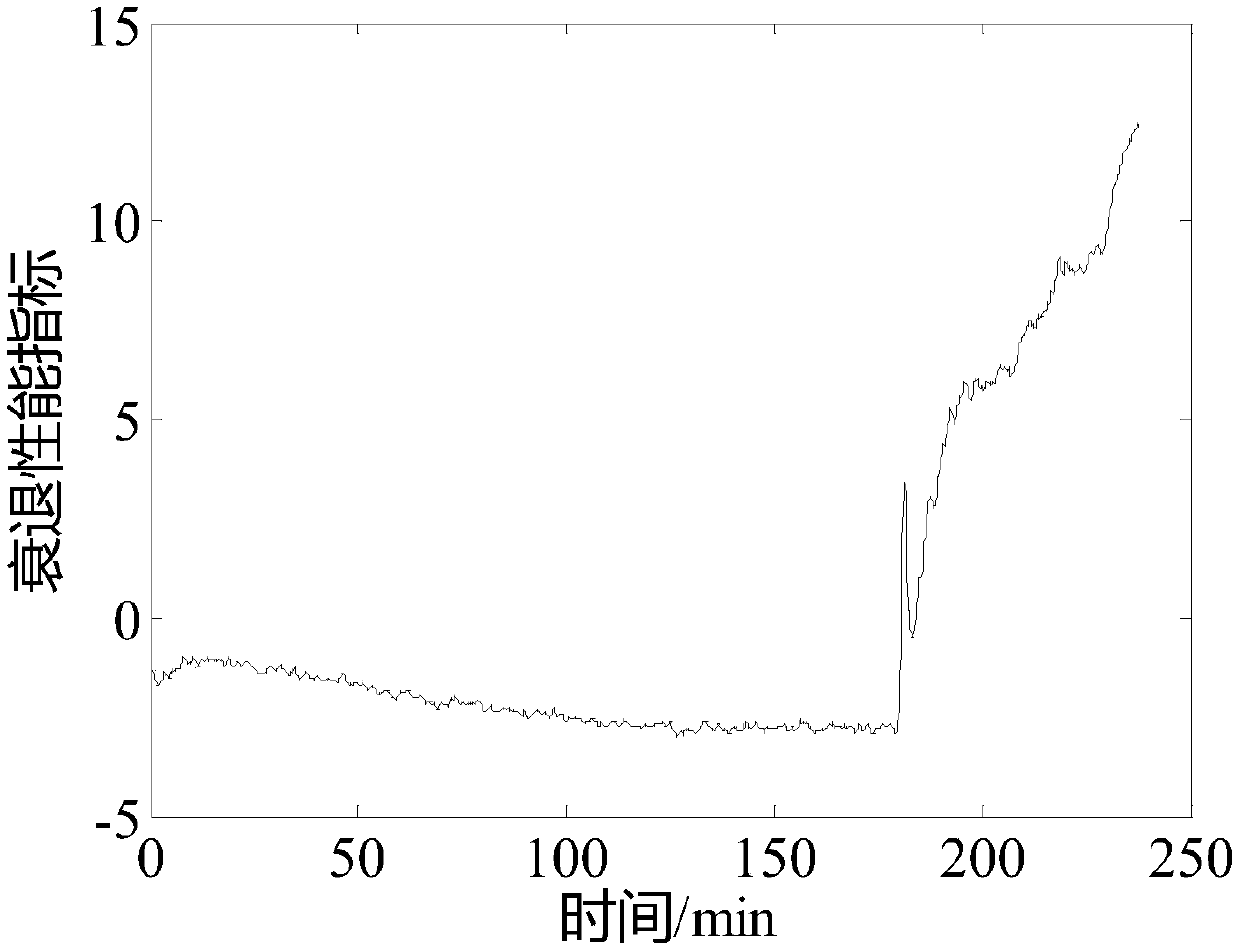

[0057] refer to figure 1 , a dynamic prediction method for rolling bearing life based on multiple features and phase space, including the following steps:

[0058] The first step is to obtain the vibration signal of the rolling bearing, and extract its time domain and frequency domain characteristic indicators, as shown in Table 1, Table 2 and Table 3, x={x 1 ,x 2 ,...,x N} is the vibration signal,

[0059] Table 1 Dimensional time-domain indicators

[0060]

[0061] Table 2 Dimensionless time-domain indicators

[0062]

[0063] In the frequency domain index calculation, s(k) is the spectrum of the signal x, k=1,2,...,K, K is the number of spectral lines, f k is the frequency value of the kth spectral line,

[0064] Table 3 Frequency Domain Indicators

[0065]

[0066]

[0067] In the second step, in order to reduce the difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com