Closed ABS solenoid valve test device

A technology of ABS solenoid valve and testing device, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of low work efficiency and achieve high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

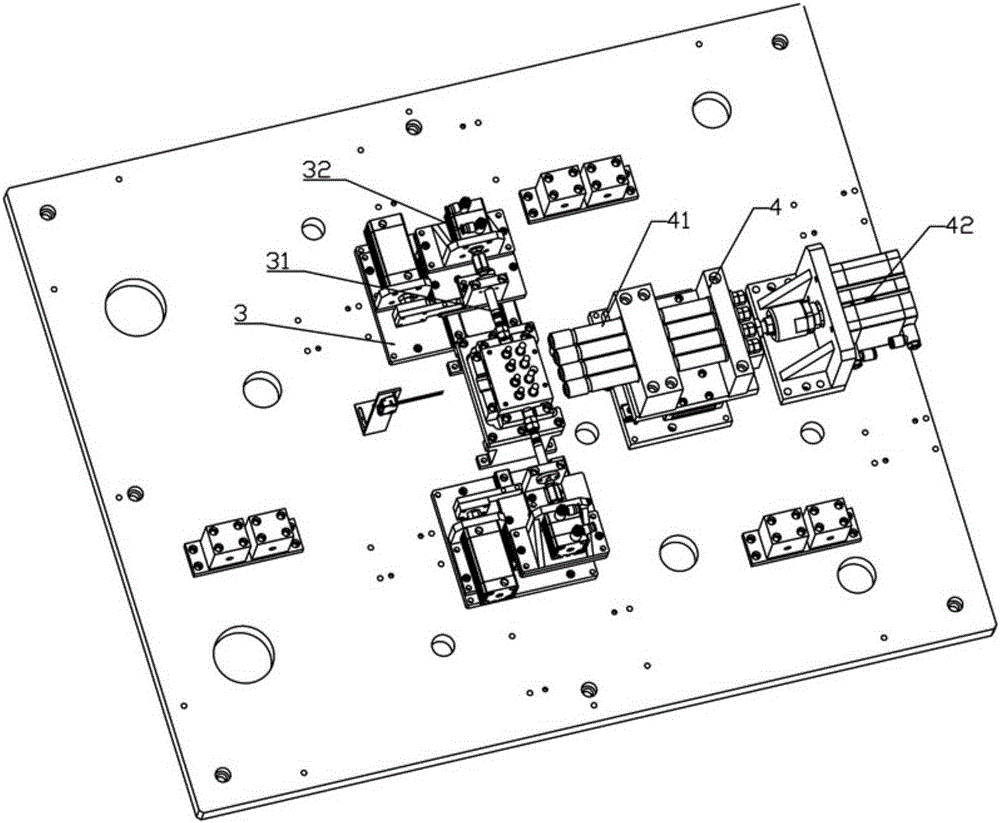

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

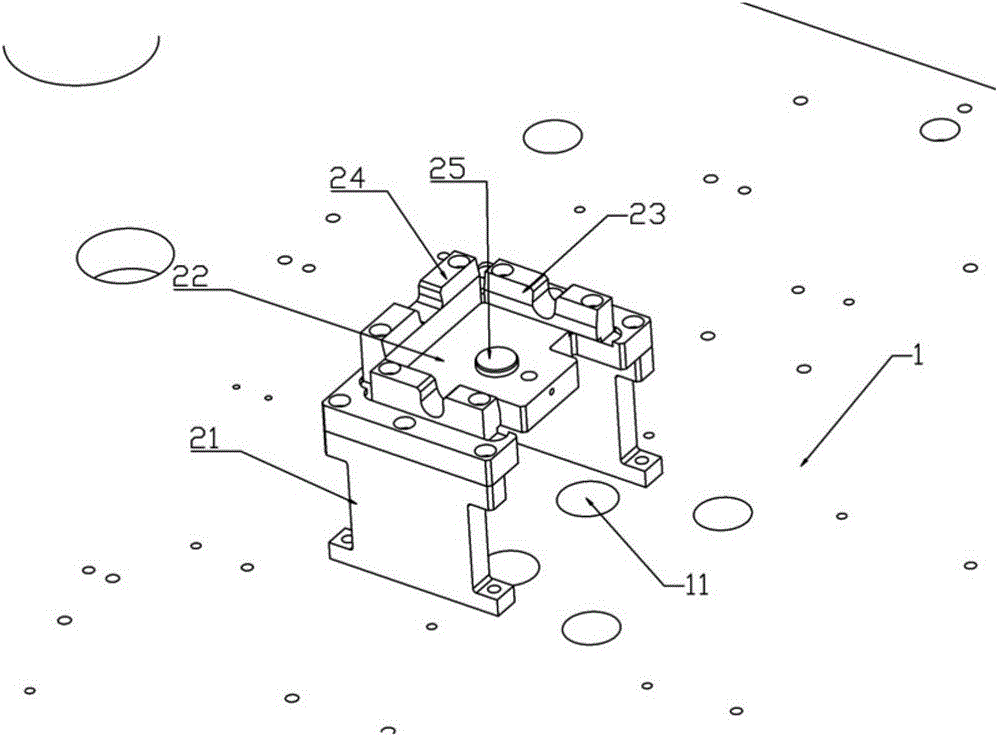

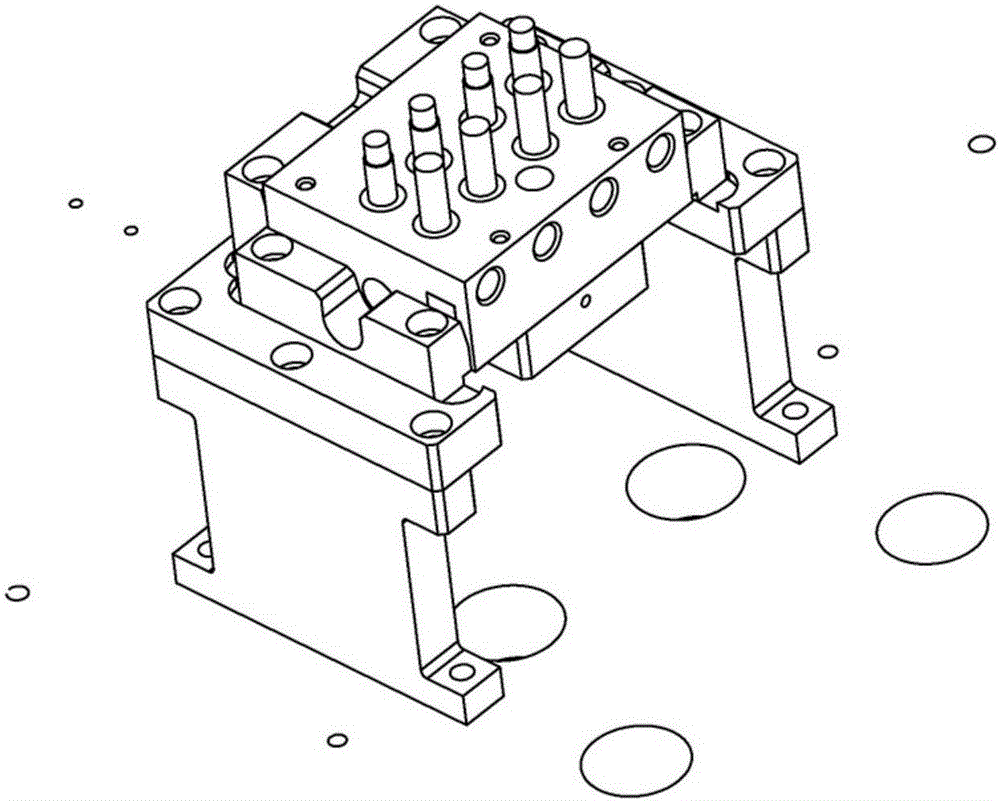

[0035] see Figure 1-8 , a closed ABS solenoid valve testing device, has:

[0036] Platen, positioning mechanism, blocking mechanism, conveying mechanism, pressing mechanism, upper frame, lower frame and electric control box;

[0037] The platen is installed on the lower frame; the upper frame closes the platen, positioning mechanism, blocking mechanism, conveying mechanism and pressing mechanism;

[0038] The platen is installed on the lower frame;

[0039] Positioning agencies include:

[0040] Two support plates are arranged on the platen;

[0041] The positioning plate is installed on two support plates for placing the ABS solenoid valve, and the positioning plate is square;

[0042] The limit block is arranged on the two oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com