Magnetorheological fluid damper

A technology of magnetorheological fluid and damper, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of high development cost and high production precision requirements, and achieve low production cost and damping output. Wide-ranging, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

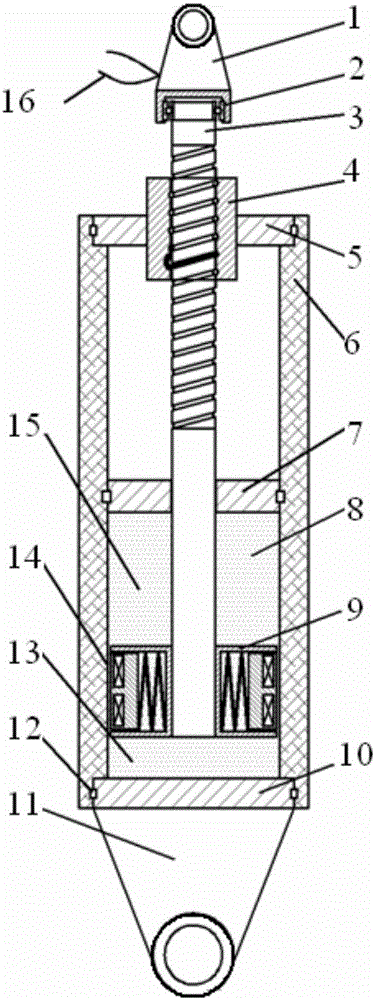

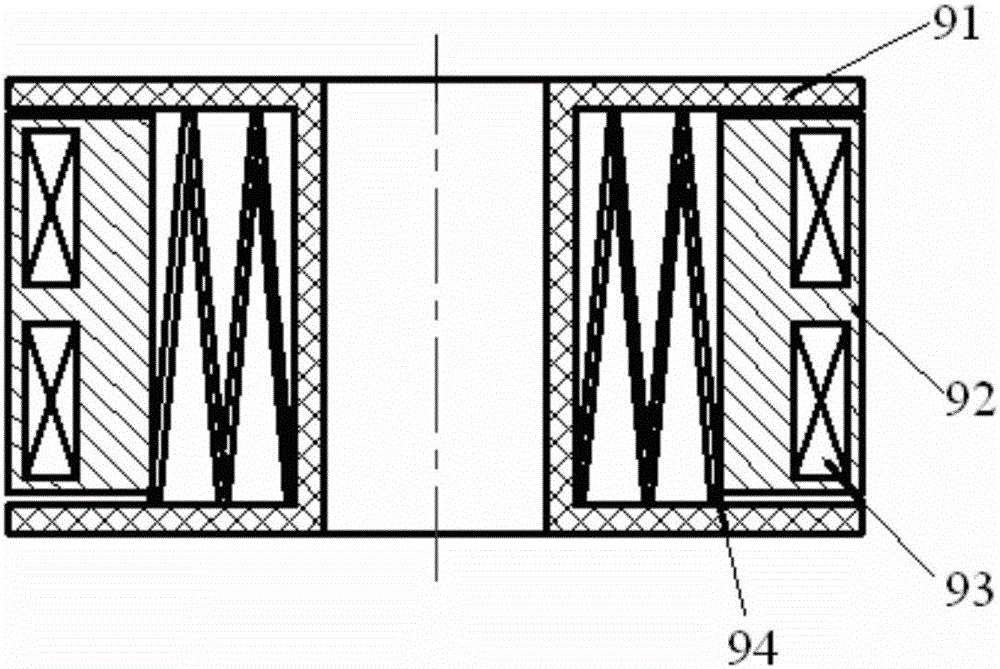

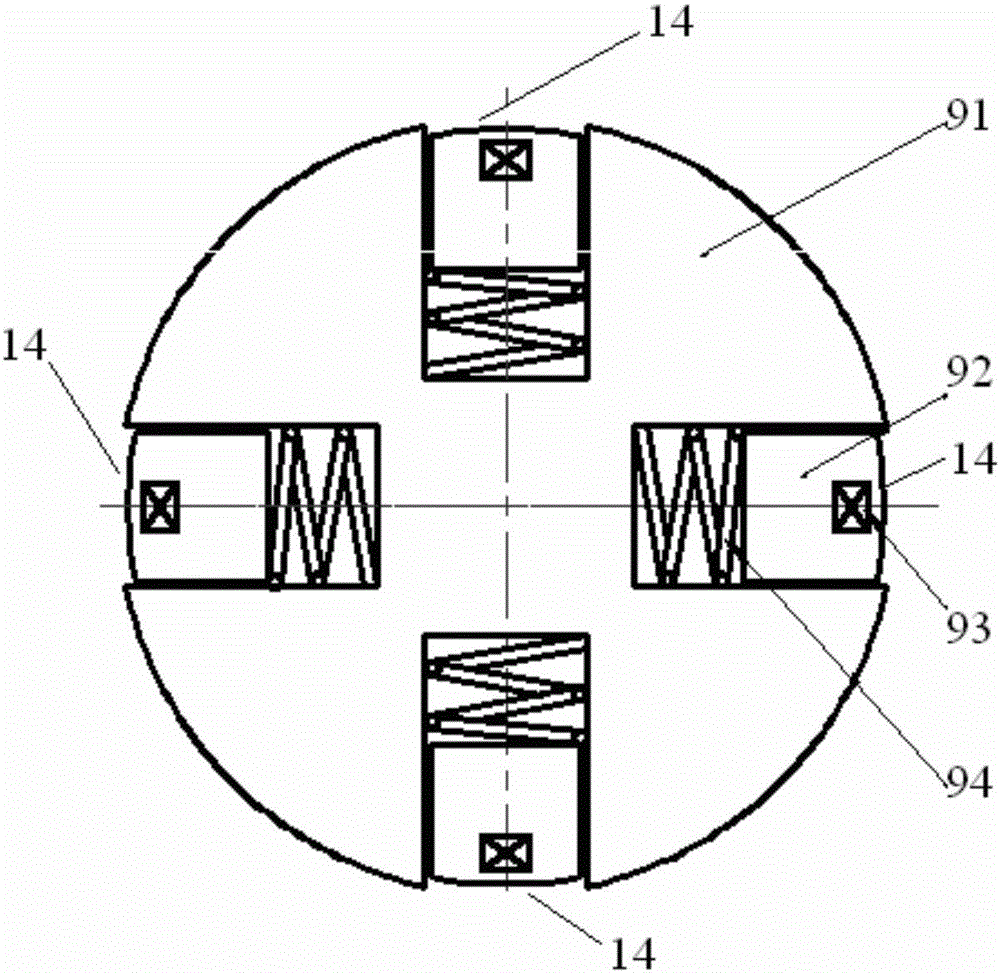

[0025] Such as Figure 1 to Figure 4 Shown is the magneto-rheological fluid damper of the present invention, which includes a working cylinder 6, a piston 9 and a slidable piston rod 3 located in the working cylinder 6, and the piston rod 3 passes through the upper cover 5 and your sealing cover 7. The lower end of the piston rod 3 is inserted into the working cylinder 6 and connected with the piston 9; the outer circular surface of the piston 9 is in close contact with the inner wall of the working cylinder 6; the piston 9 divides the working cylinder 6 into two working chambers, that is, the upper Working chamber 15 and lower wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com