Anti-corrosion hydraulic oil tank for tractor

A technology of hydraulic oil tank and tractor, which is applied to mechanical equipment, fluid pressure actuating device, fluid pressure actuating system components, etc., can solve the problems of insufficient filtering force of hydraulic oil tank, affecting power transmission effect and high maintenance cost, etc. To achieve the effect of easy assembly and manufacturing process, rapid filtration and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

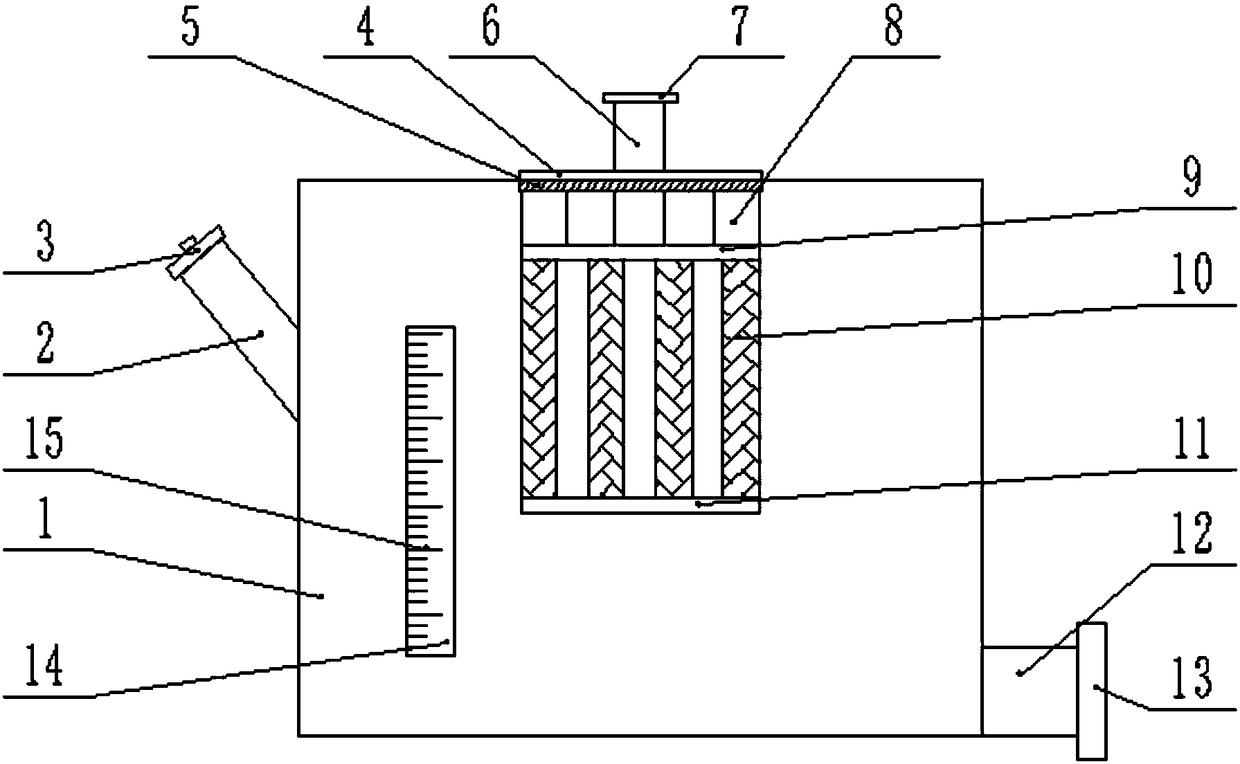

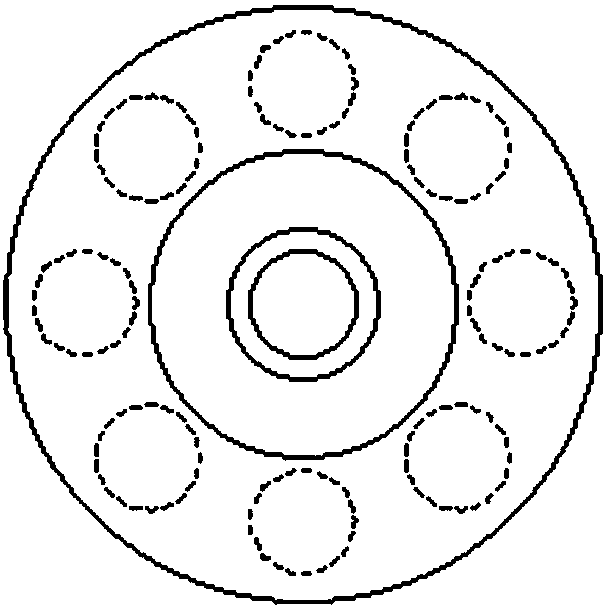

[0015] Combine below Figure 1-2 The structure of the hydraulic oil tank for the tractor of the present invention is described in detail. A hydraulic oil tank for anti-corrosion tractors, comprising a tank body 1, the upper left end of the tank body 1 is fixedly connected to the fuel filler port 2, the upper end of the fuel filler port 2 is fixedly connected to the fuel filler cap 3, and the upper end of the tank body 1 It is fixedly connected with the cleaning cover 4, the lower end of the cleaning cover 4 is fixedly connected with the sealing ring 5, the sealing ring 5 is in close contact with the box body 1, and the middle of the cleaning cover 4 is passed through the oil return port 6, so The upper end of the oil return port 6 is fixedly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com