A double-body double-suction canned pump

A technology of double pump bodies and canned pumps, which is applied in the direction of pumps, pump components, pump devices, etc., can solve the problems of the scope of application of canned pumps and the difficulty in operating reliability to meet the frequent changes in the working conditions of the liquid delivery system, so as to improve the efficiency of the unit, The effect of improving hydraulic performance and improving flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

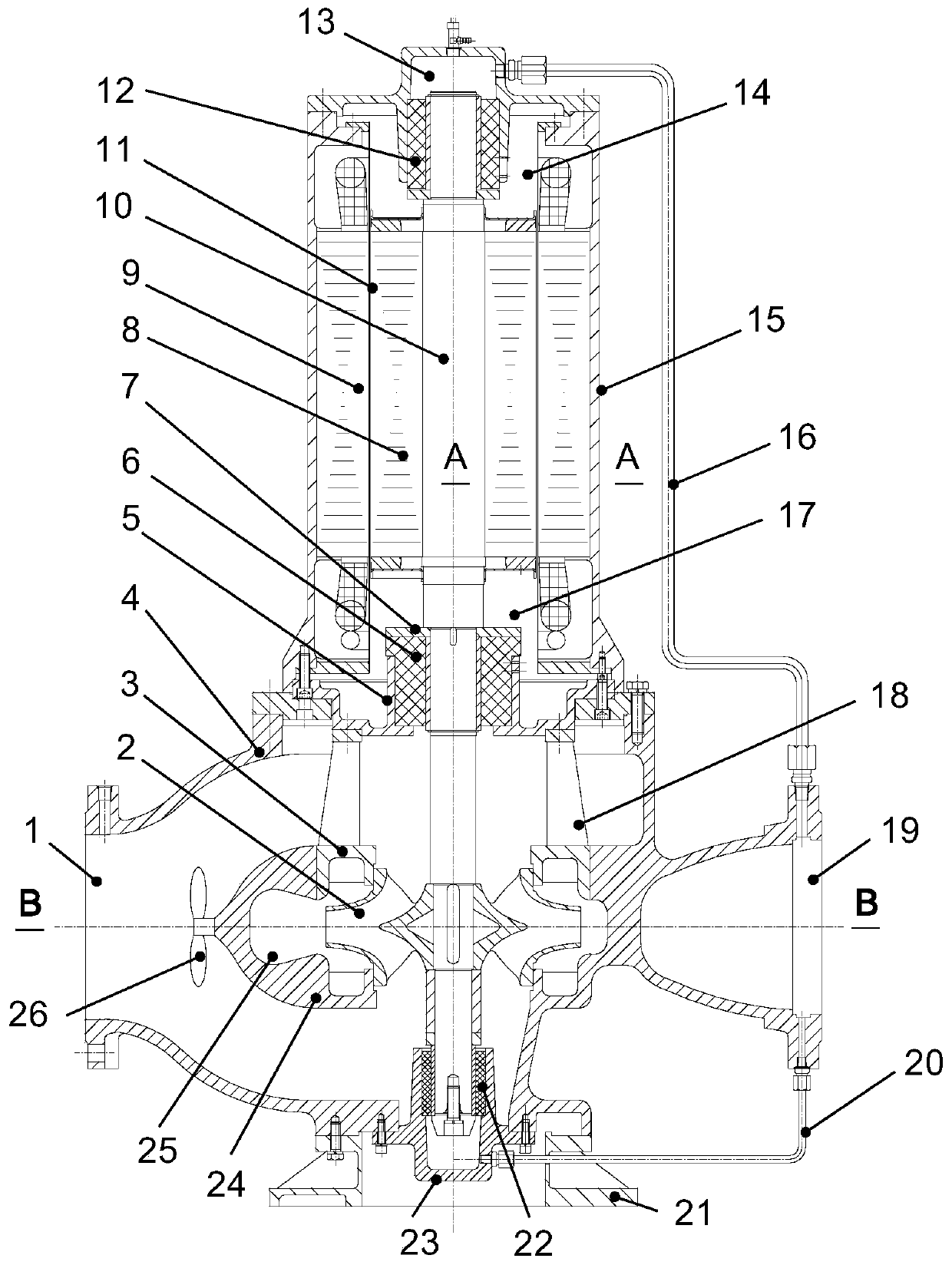

[0016] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings.

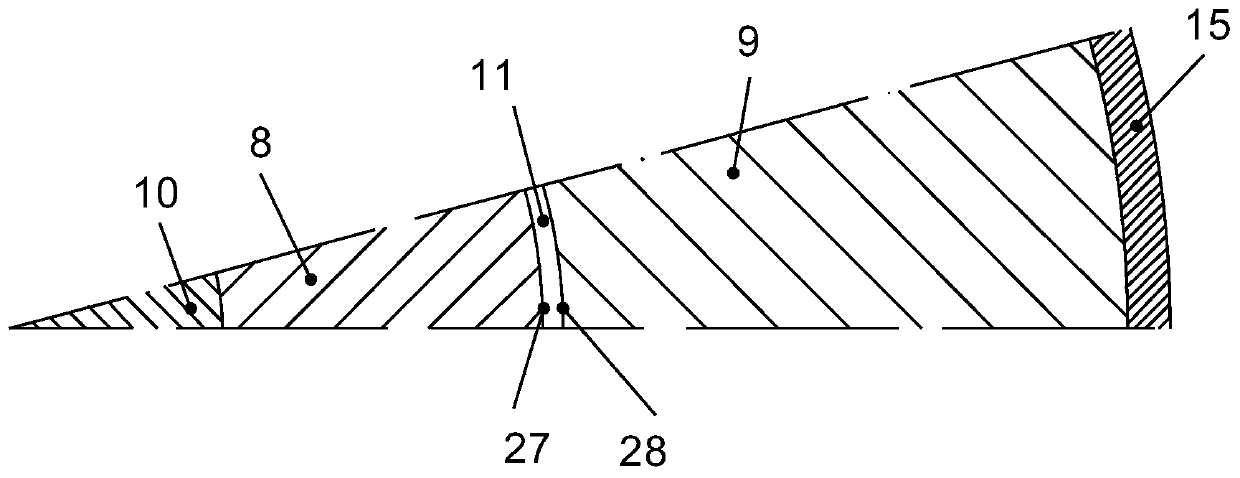

[0017] Such as Figure 1-2 as shown, figure 1 The main cross-sectional view of a double-body double-suction shielded pump provided by the present invention includes a pump inlet 1, a pump outlet 19, a double-suction impeller 2, a sealing section 3, a pump body 4, a pressure water chamber 25, an auxiliary impeller 26, Bearing support 5, lower guide bearing 6, thrust plate 7, motor rotor 8, motor stator 9, rotor shielding sleeve 27, stator shielding sleeve 28, main shaft 10, upper guide bearing 12, pump base 21, auxiliary bearing 22, auxiliary bearing Support 23, the outlet section 29 of the pump body, the outlet section 30 of the inner pump body, the first suction port 31 of the double-suction impeller and the second suction port 32 of the double-suction impeller, wherein the pump inlet 1, the pump outlet 19, and the double-suction impell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com