Ultrasonic variable-frequency blockage removing, oil outlet increasing and injection increasing device

An ultrasonic and plugging-removing technology, which is applied in cleaning equipment, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as difficult to meet the needs of deep plugging removal, short-circuit damage of electrical system, low electro-acoustic conversion efficiency, etc., to achieve The effect of reducing power, reducing acoustic wave loss, and improving electroacoustic conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

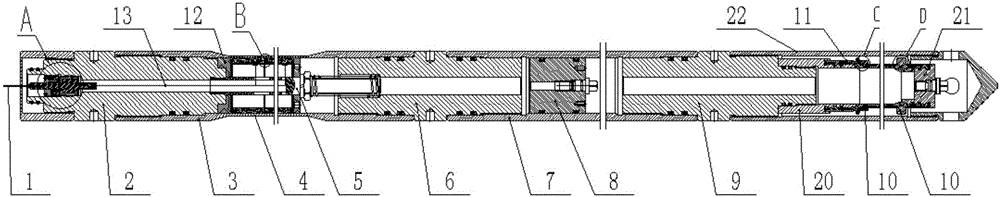

[0024] The present invention will be further described below in conjunction with accompanying drawing:

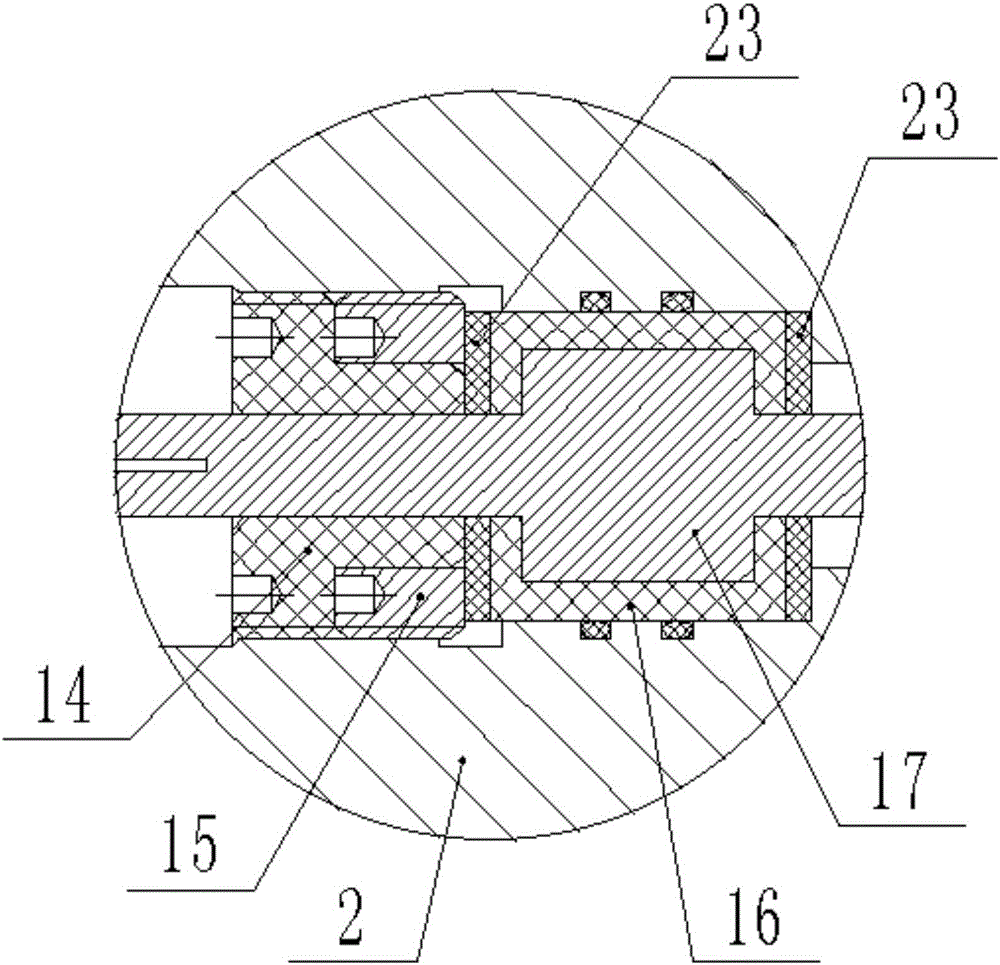

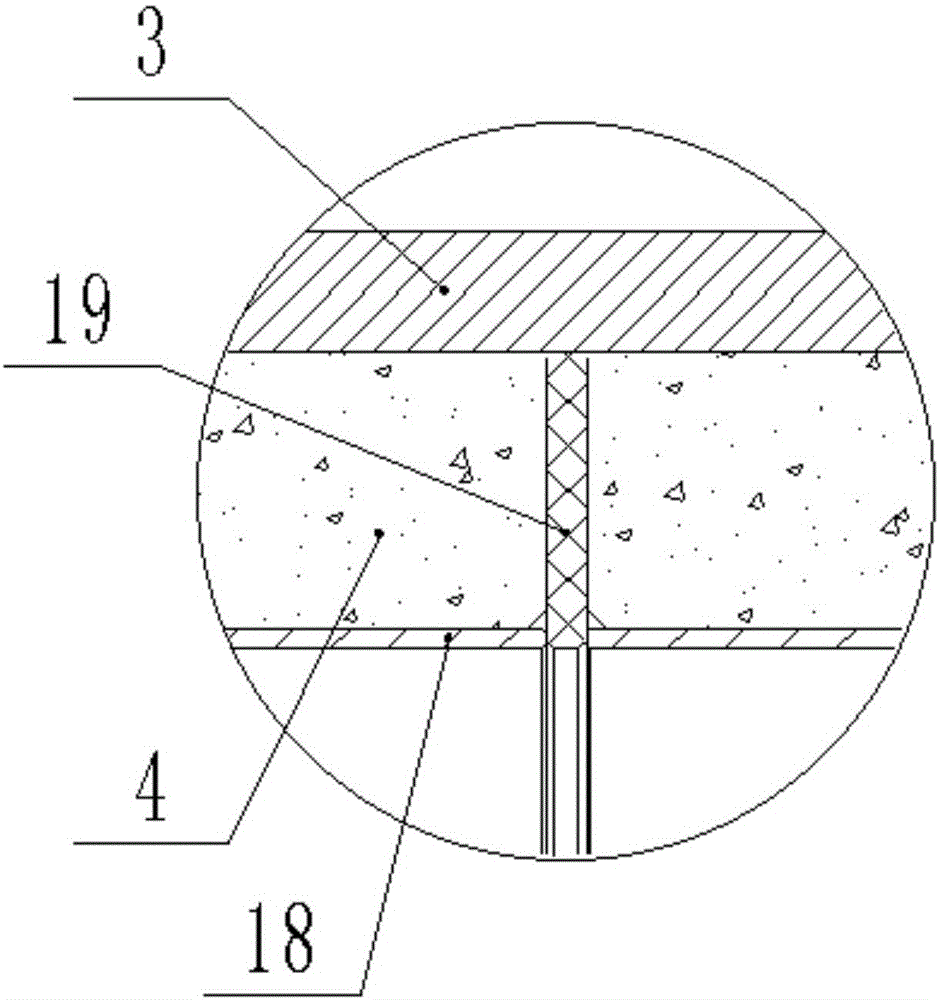

[0025] The ultrasonic frequency conversion deblocking and oil increasing device includes a cable 1, a cable connector 2, a protection cylinder 3, a piezoelectric ceramic 4 and a pressure balance rubber cylinder 11, and also includes a sealing piston 8. The cable 1 is connected to the On the upper side of the cable connecting body 2 , the protective tube 3 is fixedly connected to the outside of the lower end of the cable connecting body 2 .

[0026] The piezoelectric ceramic 4 is pre-tightened and fixed on the inner side of the protective tube 3 through the gland 12. Compared with the way of installing the piezoelectric ceramic 4 with a transition medium, the piezoelectric ceramic 4 is directly pre-tightened and fixed on the inner wall of the protective tube 3, which can The ultrasonic waves are emitted directly, which reduces the sound wave loss of the transition medium, im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com