Method of integrating nano-electrospinning and short-fiber vortex spinning into yarn

A technology of electrospinning and eddy current spinning, which is applied in spinning machines, fiber processing, open-end spinning machines, etc. It can solve the problem of nanofibers not realizing high-function and high-quality nano-yarn production, weak fiber cohesion, and high strength. low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

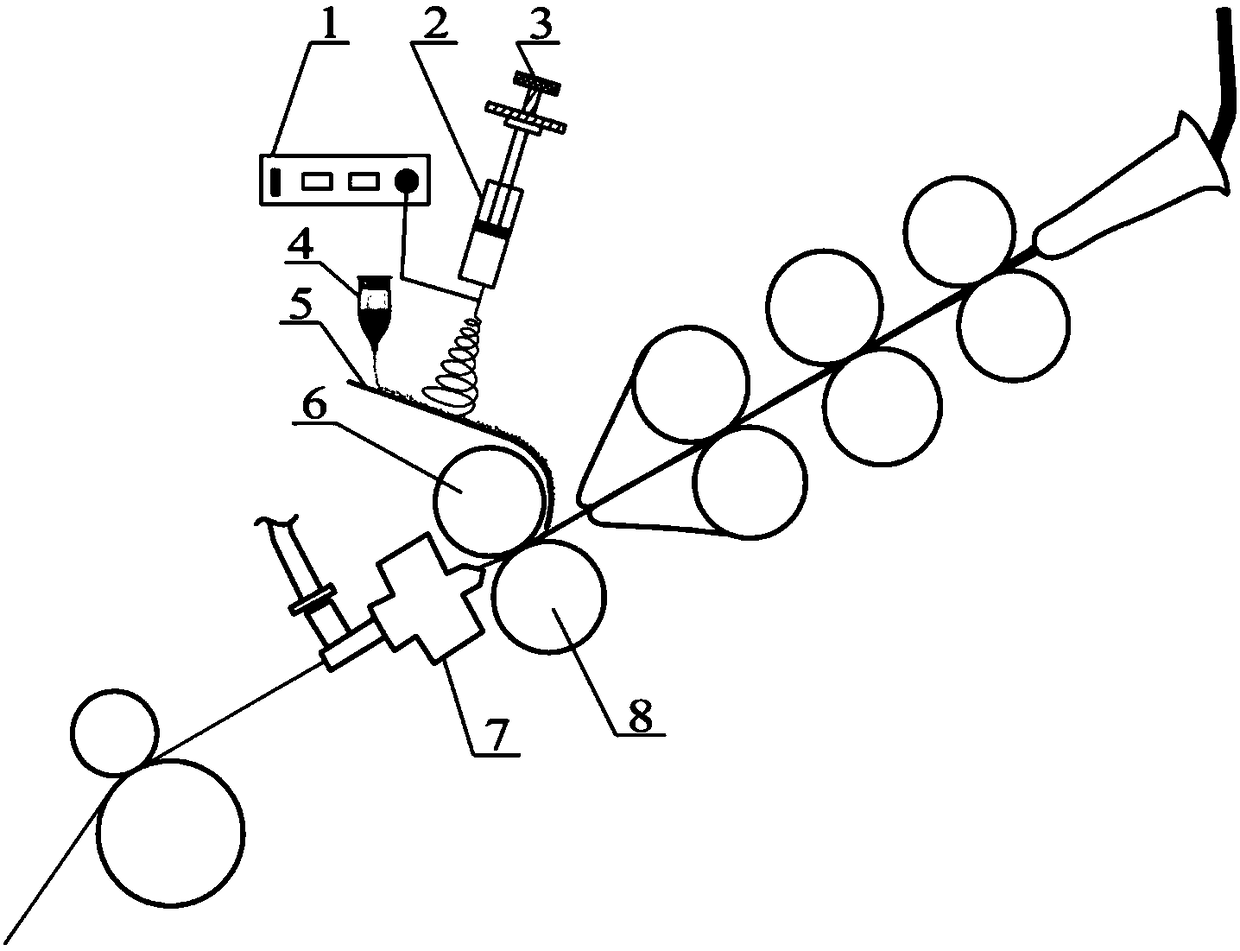

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] see Attachment.

[0013] A method for integrating nano-electrospinning and short-fiber vortex spinning into yarn, including an electrospinning device and a vortex spinning machine, using a nano-powder release device above the front rubber roller of each drafting system of the vortex spinning machine 4 And the electrospinning device, the nano-powder releasing device 4 is fixedly installed on the cradle of the vortex spinning machine, the upper part of the nano-powder releasing device 4 is a powder storage cavity, and the lower part is a powder outlet, and the powder outlet is flat and slit-shaped, and the powder outlet The opening is parallel to the axis of the front rubber roller 6. The receiving plate 5 of the electrospinning device is set on the cradle of the eddy current frame through an insulating base. One end of the receiving plate 5 is the outpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com