Brewing method of full-wheat-malt turbid beer

A cloudy beer and wheat malt technology, which is applied in the field of food processing, can solve the problems of prohibitive production of whole wheat malt beer, no whole wheat malt beer, and difficulty in forming a filter layer, so as to enrich product types and improve the monotony and taste of beer varieties Single consumption status, the effect of cloudy wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

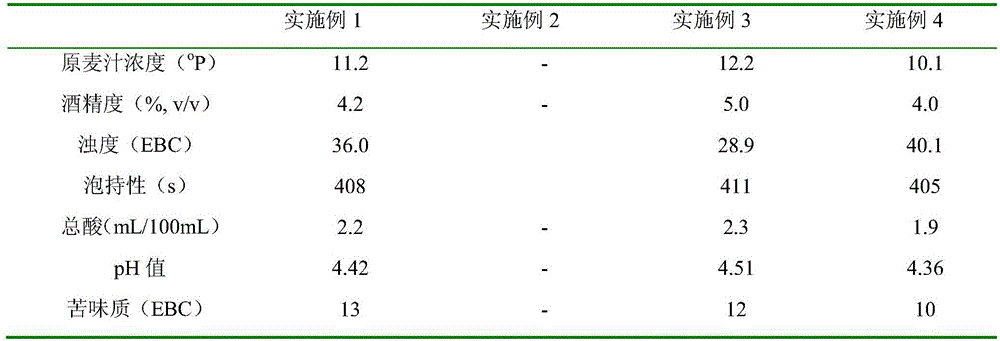

Embodiment 1

[0019] 1. Raw materials: wheat germ:wheat bran=40:3 (mass ratio); wheat beer yeast, hops.

[0020] 2. Crush the wheat germ into the mash pot, soak at 40°C for 30 minutes, raise the temperature to 55°C at 1°C / min and maintain it for 25 minutes for protein rest, raise the temperature to 70°C at 1°C / min to liquefy the starch until the iodine reaction disappears, and raise the temperature to 76°C to obtain mash, ready for hot filtration;

[0021] 3. Put the coarse wheat bran into the filter tank, soak and wash with the preheated water of the filter tank at 76°C, drain the washing water to remove the residual soluble substances in the wheat bran, and let it rest for 30 minutes to form a wort filter layer;

[0022] 4. Pump the saccharification mash prepared in step 2) into the lauter tank after the treatment in step 3), use the coarse wheat bran soaked and cleaned in step 3) as the filter medium to carry out hot filtration and washing, and obtain filtered wort respectively and wort...

Embodiment 2

[0029] 1. Raw material: wheat germ:wheat bran=40:0 (mass ratio). Wheat beer yeast, hops.

[0030] 2. Crush the wheat germ into the mash pot, soak at 45°C for 30 minutes, raise the temperature at 1°C / min to 55°C and maintain it for 60 minutes for protein rest, raise the temperature at 1°C / min to 70°C to liquefy the starch until the iodine reaction disappears, and raise the temperature to 76°C to obtain mash, to be filtered;

[0031] 3. Pump the saccharification mash obtained in step 2) into a filter tank preheated by hot water at 76°C, filter and wash the grains to obtain filtered wort and washed wort respectively;

[0032] 4. Pump the filtered wort and washed wort obtained in step 3) to the boiling pot respectively, boil at 102°C for 65 minutes, and add hops after the initial boiling for 10 minutes;

[0033] 5. Pump the boiled wort in step 4) to the whirling sedimentation tank to remove thermal coagulation and hop grains. After the wort is cooled to 14°C, feed the sterile wi...

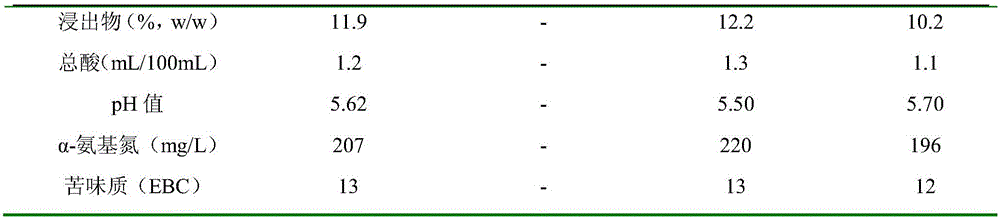

Embodiment 3

[0038] 1. Raw materials: wheat germ:wheat bran=40:3 (mass ratio). Wheat beer yeast, hops.

[0039] 2. Grind the wheat germ, put it into the mash pot, soak it at 44°C for 30 minutes, raise the temperature at 1°C / min to 52°C and maintain it for 40 minutes to stop the protein, raise the temperature at 1°C / min to 70°C to liquefy the starch until the iodine reaction disappears, and raise the temperature to 76°C Obtain saccharification mash, to be filtered;

[0040] 3. Put the coarse wheat bran into the filter tank, soak and wash with the preheated water of the filter tank at 76°C, drain the washing water to remove the residual soluble substances in the wheat bran, and stand still for 40 minutes to form the wort filter layer;

[0041] 4. Pump the saccharification mash prepared in step 2) into the lauter tank after the treatment in step 3), use the coarse wheat bran soaked and cleaned in step 3) as the filter medium to carry out hot filtration and washing, and filter wort respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com