Treating agent for mirex-contaminated sludge and preparation method thereof

A technology of sludge treatment and mirex, which is applied in the direction of sludge treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of soil secondary pollution and high cost, and achieve simple treatment process and low cost , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

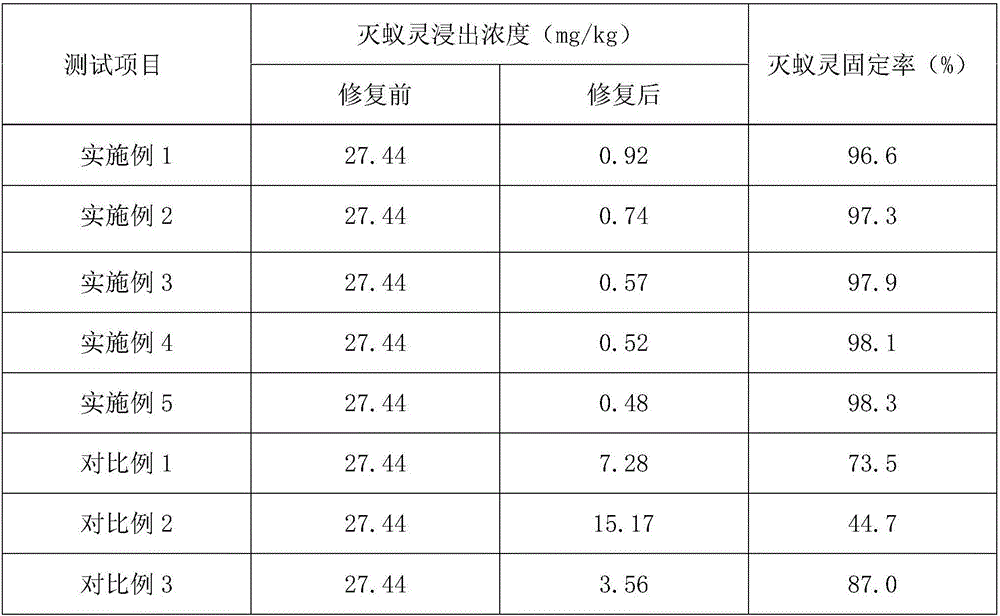

Examples

Embodiment 1

[0020] A mirex polluted sludge treatment agent, the main raw materials in parts by weight are: 24 parts of nano-modified sludge, 5 parts of pebbles, 14 parts of diethylenetriaminepentaacetic acid, 9 parts of polyacrylamide, decabromodiphenyl 10 parts of ethane, 3 parts of glass fiber, 0.2 part of heavy calcium carbonate, and 0.2 part of potassium chloride; the preparation method of the nano-modified sludge: first triphenyl phosphite, polyethylene glycol monolaurate , isoprene and vacuum filtration treatment to obtain the mixture, then react borax, sludge and the mixture under microwave to obtain nano-modified sludge; the mesh number of the cobblestone is 800 mesh; the heavy The mesh number of calcium carbonate is 1200 mesh.

[0021] The preparation method of described mirex polluted sludge treatment agent, concrete steps are:

[0022] (1) First, drop cobblestone and diethylenetriaminepentaacetic acid into the nano-modified sludge, process it in a twin-shaft agitator for 20 mi...

Embodiment 2

[0027] A mirex polluted sludge treatment agent, the main raw materials in parts by weight are: 24 parts of nano-modified sludge, 6 parts of pebbles, 15 parts of diethylenetriaminepentaacetic acid, 9 parts of polyacrylamide, decabromodiphenyl 10 parts of ethane, 3 parts of glass fiber, 0.2 part of heavy calcium carbonate, and 0.2 part of potassium chloride; the preparation method of the nano-modified sludge: first triphenyl phosphite, polyethylene glycol monolaurate , isoprene and vacuum filtration treatment to obtain the mixture, then react borax, sludge and the mixture under microwave to obtain nano-modified sludge; the mesh number of the cobblestone is 800 mesh; the heavy The mesh number of calcium carbonate is 1200 mesh.

[0028] The preparation method of described mirex polluted sludge treatment agent, concrete steps are:

[0029] (1) First, drop cobblestone and diethylenetriaminepentaacetic acid into the nano-modified sludge, process it in a twin-shaft agitator for 20 mi...

Embodiment 3

[0034] A mirex polluted sludge treatment agent, the main raw materials in parts by weight are: 26 parts of nano-modified sludge, 8 parts of pebbles, 16 parts of diethylenetriaminepentaacetic acid, 10 parts of polyacrylamide, decabromodiphenyl 13 parts of ethane, 4 parts of glass fiber, 0.3 part of heavy calcium carbonate, and 0.3 part of potassium chloride; the preparation method of the nano-modified sludge: first triphenyl phosphite, polyethylene glycol monolaurate , isoprene and vacuum filtration treatment to obtain the mixture, then react borax, sludge and the mixture under microwave to obtain nano-modified sludge; the mesh number of the cobblestone is 800 mesh; the heavy The mesh number of calcium carbonate is 1200 mesh.

[0035] The preparation method of described mirex polluted sludge treatment agent, concrete steps are:

[0036] (1) First, drop cobblestone and diethylenetriaminepentaacetic acid into the nano-modified sludge, process it in a twin-shaft agitator for 20 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com