Rear-mounted driving high-speed palletizing system

A palletizing system, high-speed technology, applied in the direction of object stacking, object depalletizing, conveyor objects, etc., can solve the problems of large number of workers, poor quality of palletizing and packaging, and low speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

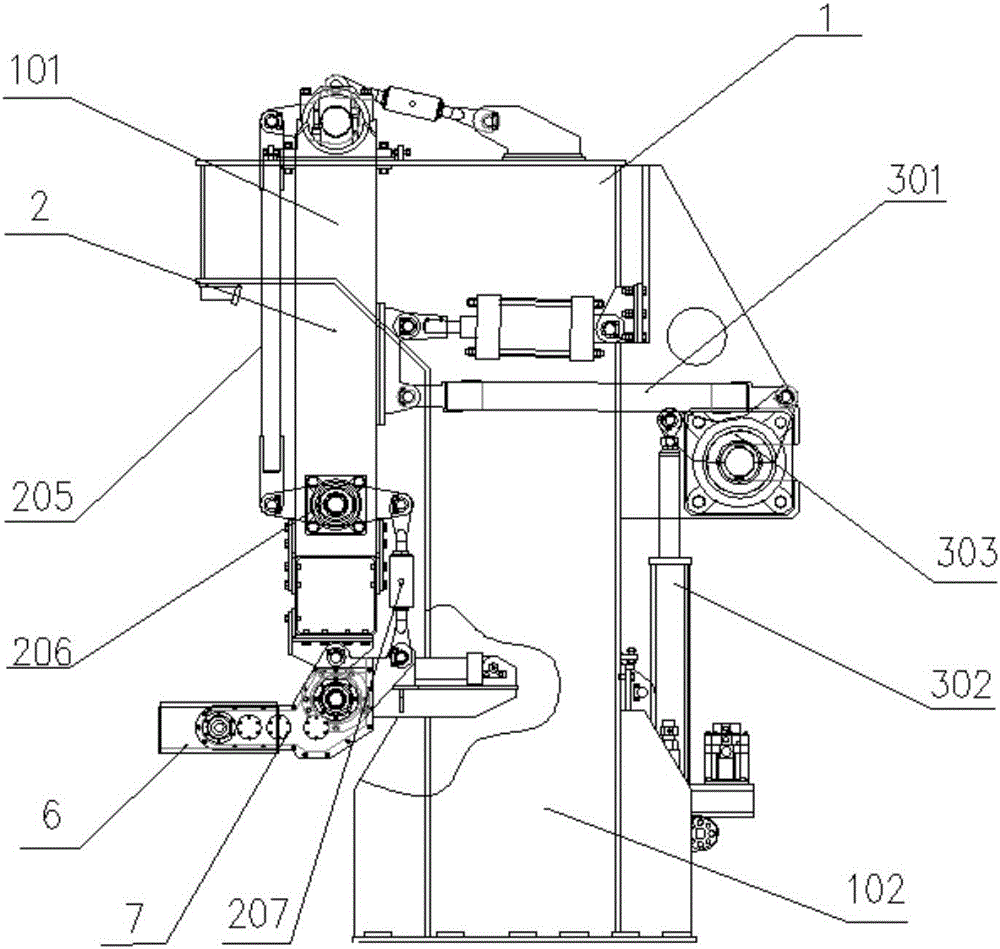

[0057] The post-driven high-speed palletizing system of this embodiment includes a frame 1, a boom 2, a rear-mounted drive device, a wrist 7, a turning electromagnet 6, and a lifting platform arranged at the input end of the frame;

[0058] The frame 1 includes a horizontal section 101 and a vertical section 102, the rear end of the horizontal section 101 of the frame is connected to the top of the vertical section 102, and the front end of the horizontal section 101 of the frame is hinged to the upper end of the boom 2 ;

[0059] The rear-mounted driving device is fixedly connected to the vertical section 102 of the frame 1 and is hinged with the boom 2; the lower end of the boom 2 is connected with a wrist 7, and the wrist 7 is provided with a horizontal holding mechanism , the front end of the wrist 7 is rotatably connected with an overturning electromagnet 6; the bottom end of the iron side wall of the overturning electromagnet 6 is slidably connected with a guide tooth pl...

Embodiment 2

[0068] The positioning block in this embodiment includes an alternate block; the alternate block includes front and rear blocks arranged in sequence along the moving direction of the profile, and a block lifting mechanism that drives the front block up and down. The side of the block facing the direction of profile movement is equipped with a limit trigger mechanism;

[0069] The positioning stopper also includes a translation stopper; the translation stopper includes a movement stopper and a stopper translation mechanism that drives the movement stopper to reciprocate along the movement direction of the profile. The limit trigger mechanism is set on the side;

[0070] When the angle steel is in positive size, it is shape, when the angle steel is reversed, it is superimposed on the angle steel that was previously coded, showing The positive code means that the opening of the angle steel is facing downward, and the negative code means that the opening of the angle steel is ...

Embodiment 3

[0073] The flipping electromagnet described in this embodiment is provided with a magnetic force control system, and the magnetic force control system includes a sensor for detecting the position of the electromagnet and a control device for controlling the magnetic force of the electromagnet; The detected position information of the flipping electromagnet outputs control information to adjust the magnetic force of the flipping electromagnet;

[0074] The method for the control device to output control information to adjust the magnetic force of the flip electromagnet according to the received position information of the flip electromagnet detected by the sensor is: when it is detected that the flip electromagnet flips to the first phase, the control device The magnetic force of the control electromagnet is located in the first interval; when it is detected that the flipping electromagnet is flipped to another phase, the control device controls the magnetic force of the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com