Garbage transfer system

A garbage and garbage truck technology, applied in the field of garbage transfer system, can solve the problems of lack of control system, waste of human resources, low work efficiency, etc., and achieve the effects of avoiding secondary pollution, reducing secondary pollution, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

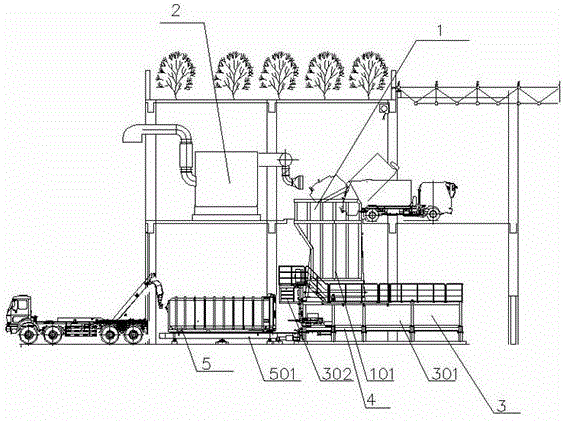

[0024] A garbage transfer system, characterized in that it includes: a discharge station 1 for dumping garbage by a garbage truck, a cleaning station 2 for dedusting and deodorizing the discharge station, and a transposition station for packing, compressing and pushing the garbage 3. The counting station 4 and the sub-loading station 5 for weighing the weight of the garbage, the unloading station 1 is arranged on the top of the transposition station 3, and the counting station 4 is arranged on the transposition station 3. The bottom of the position station 3, the sub-assembly loading station 5 is arranged on one side of the position change station 3 and is in contact with the position change station 3.

[0025] The transposition station 3 includes: a transposition structure of the transposition door, and the transposition structure comprises: a push head for transposition and a sealing plate for transposition, the push head is provided with a The presser connected with the pla...

Embodiment 2

[0027] A garbage transfer system, characterized in that it includes: a discharge station 1 for dumping garbage by a garbage truck, a cleaning station 2 for dedusting and deodorizing the discharge station, and a transposition station for packing, compressing and pushing the garbage 3. The counting station 4 and the sub-loading station 5 for weighing the weight of the garbage, the unloading station 1 is arranged on the top of the transposition station 3, and the counting station 4 is arranged on the transposition station 3. The bottom of the position station 3, the sub-assembly loading station 5 is arranged on one side of the position change station 3 and is in contact with the position change station 3.

[0028] The transposition station 3 includes: a transposition structure of the transposition door, and the transposition structure comprises: a push head for transposition and a sealing plate for transposition, the push head is provided with a The presser connected with the pla...

Embodiment 3

[0031] A garbage transfer system, characterized in that it includes: a discharge station 1 for dumping garbage by a garbage truck, a cleaning station 2 for dedusting and deodorizing the discharge station, and a transposition station for packing, compressing and pushing the garbage 3. The counting station 4 and the sub-loading station 5 for weighing the weight of the garbage, the unloading station 1 is arranged on the top of the transposition station 3, and the counting station 4 is arranged on the transposition station 3. The bottom of the position station 3, the sub-assembly loading station 5 is arranged on one side of the position change station 3 and is in contact with the position change station 3.

[0032] The transposition station 3 includes: a transposition structure of the transposition door, and the transposition structure comprises: a push head for transposition and a sealing plate for transposition, the push head is provided with a The presser connected with the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com