Method and apparatus for controlling a control variable of a powertrain system

A technology for controlling variables and powertrains, applied in control devices, transportation and packaging, transmission control, etc., to solve problems such as increased power consumption and reduced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

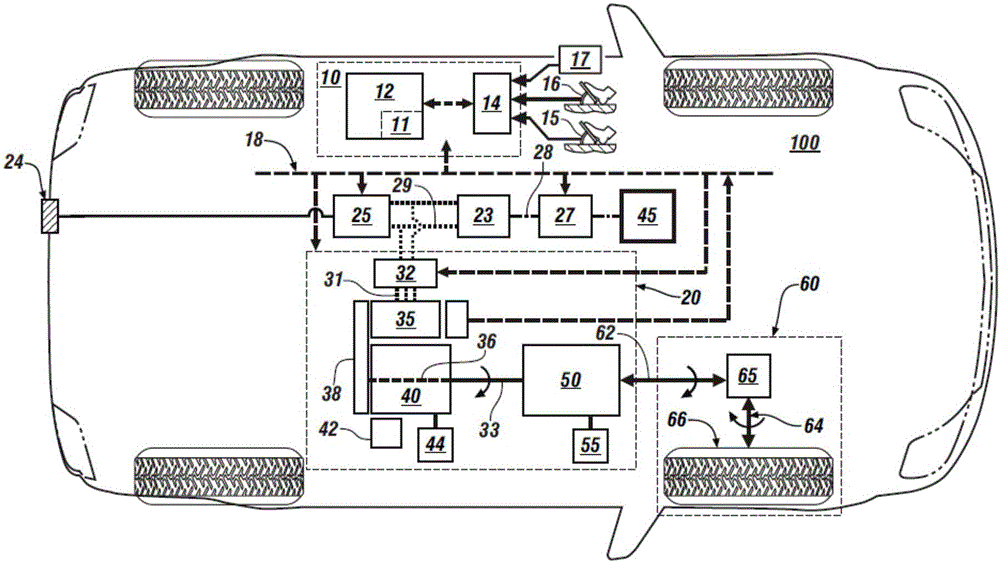

[0010] Referring now to the drawings, wherein the illustrations are for the purpose of illustrating certain exemplary embodiments only and not for the purpose of limiting the invention, figure 1 A vehicle 100 including a powertrain system 20 coupled to a powertrain system 60 and controlled by a control system 10 is schematically shown. Throughout the specification, like numerals refer to like elements. The illustrated powertrain system 20 includes a plurality of torque-generative devices including an internal combustion engine 40 and at least one electric torque machine (electric machine) 35 that transmits torque to a driveline 60 through a transmission 50 . The concepts described herein may be applied to any suitable powertrain configuration including an internal combustion engine 40 coupled to a driveline 60 via a transmission 50 .

[0011] In one embodiment, the powertrain system 20 includes a torque machine 35 rotatably mechanically coupled to a crankshaft 36 of an engine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com