Plastic extruding machine for plastic welding

A plastic welding and extruder technology, which is applied in the field of extruders, can solve the problems of inability to flexibly and accurately adjust plastic molding molds, plastic molding molds are prone to deformation, and welds do not meet the requirements, so as to achieve convenient use and avoid cracks , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

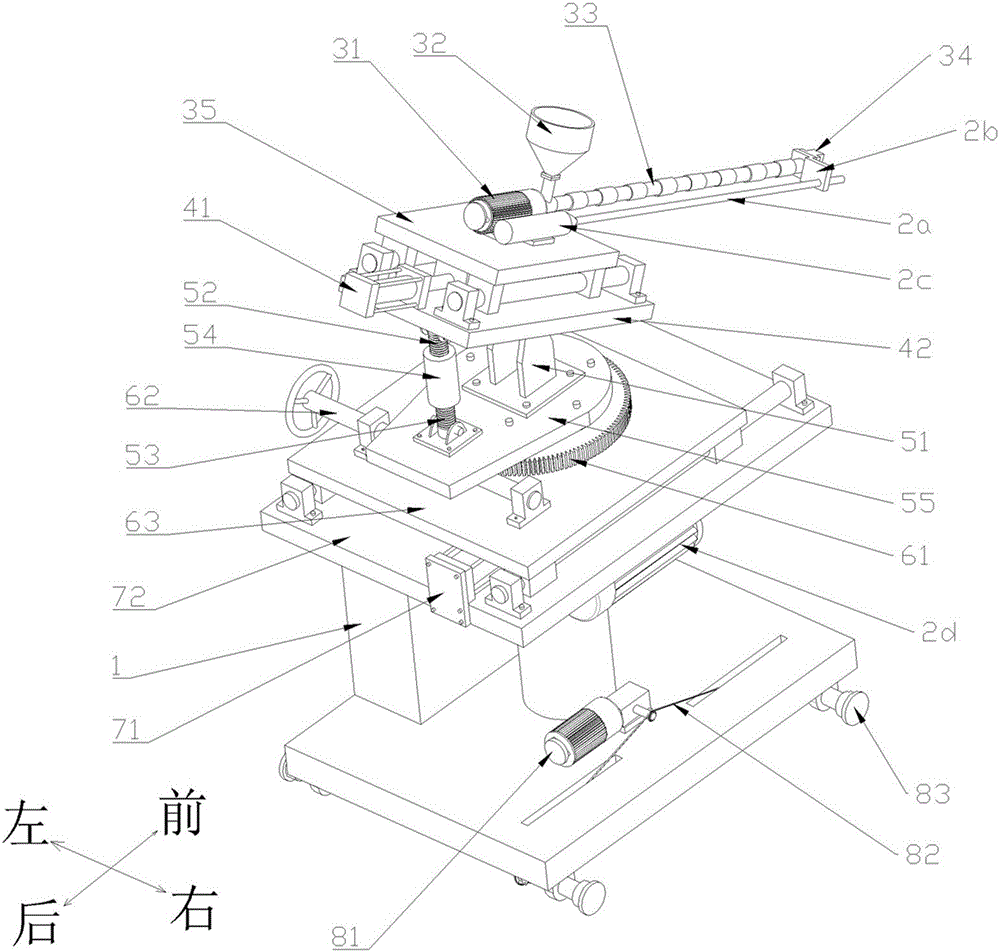

[0030] An extruder for plastic welding, such as figure 1 As shown, it includes a control panel 1, a preheating device 2, a melting device 3 and a position adjusting device.

[0031] The melting device 3 includes a main motor 31 , a feeding hopper 32 , a heating pipe 33 , a feeding screw, a plastic molding mold 34 and a melting device bottom plate 35 fixedly connected to the main motor 31 . The heating pipe 33 axis position for heating and melting plastics is provided with a feeding screw fixed on the output shaft of the main motor 31, and the top of the heating pipe 33 is provided with a feeding hopper 32 connected with the heating pipe 33, and the plastic particles are fed by the feeding hopper 32. Into the heating pipe 33, the plastic output end of the heating pipe 33 is bolted to a plastic molding die 34, so that the plastic melt is extruded by the plastic molding die 34.

[0032] The heating pipe 33 is divided into different temperature heating zones between the feeding h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com