Die-cutting machining die structure

A technology for processing molds and die-cutting, which is applied in the field of die-cutting processing mold structures, and can solve problems such as affecting work efficiency, abnormal use of products, and structural deformation of narrow-sided double-sided adhesive tape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

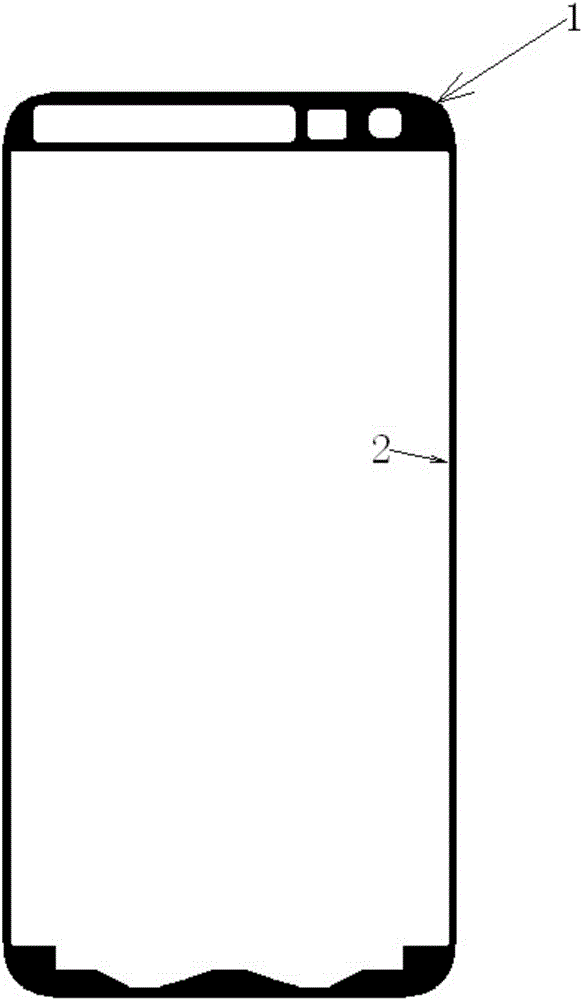

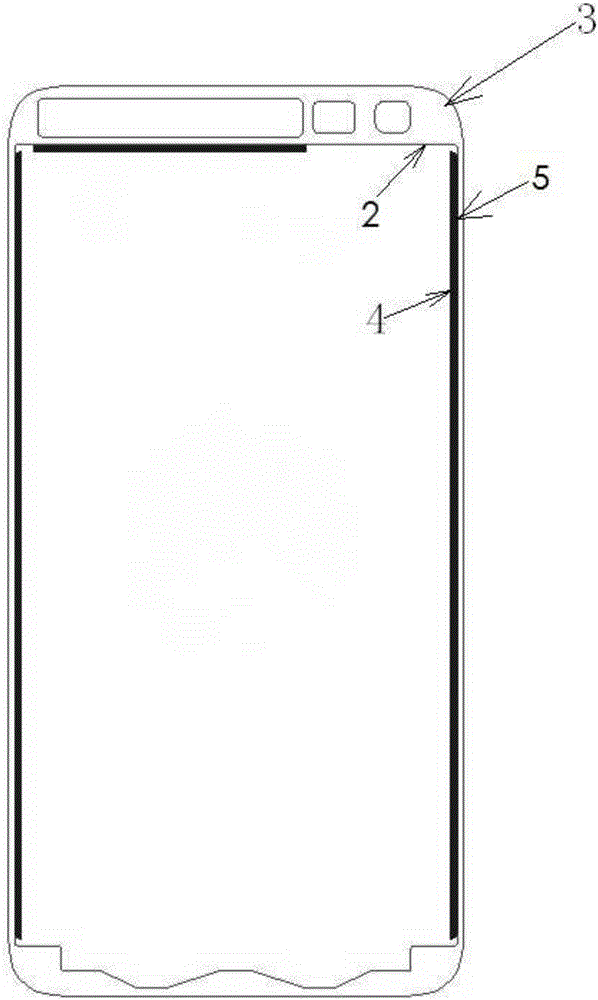

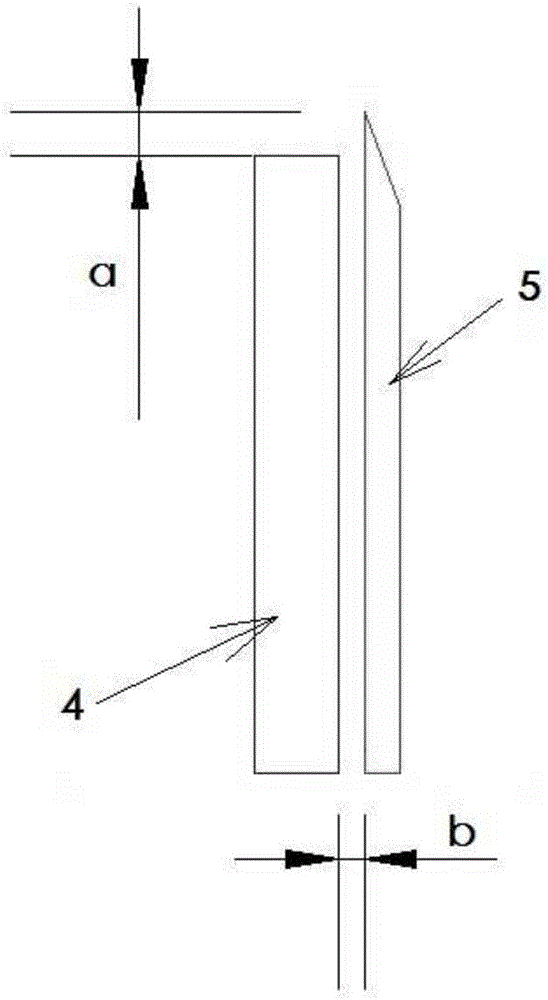

[0032] Such as figure 2 As shown, a die-cutting mold structure includes multiple rows of gear bars 4 on the inner side of the die-cutting mold 3, and each row of gear bars 4 can be multiple, and the die-cutting mold 3 uses the screen frame glue body 1 of the prior art The basic structure is provided with a mold blade 5, the distance between the mold blade 5 and the retaining strip 4 is 0.05mm, the mold blade 5 and the retaining strip 4 are located on the same horizontal line, and the length of the retaining strip 4 is the length of the straight line portion of the narrow side double-sided adhesive tape 2 , the width is 1 mm, and the height of the retaining strip 4 is 0.05 mm lower than the height of the mold blade 5 of the narrow-sided double-sided adhesive tape 2 .

[0033] On the basis of not changing the material, the current ordinary mold structure design is added with the same straight line 4 between the distance of 50.03mm-0.05mm from the narrow side double-sided adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com