Welding method for embedded nut connecting piece

A technology of embedded nuts and welding methods, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unreliable nuts, small welding surface, and nut falling off, so as to achieve full solder joints, convenient welding, and increased firmness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

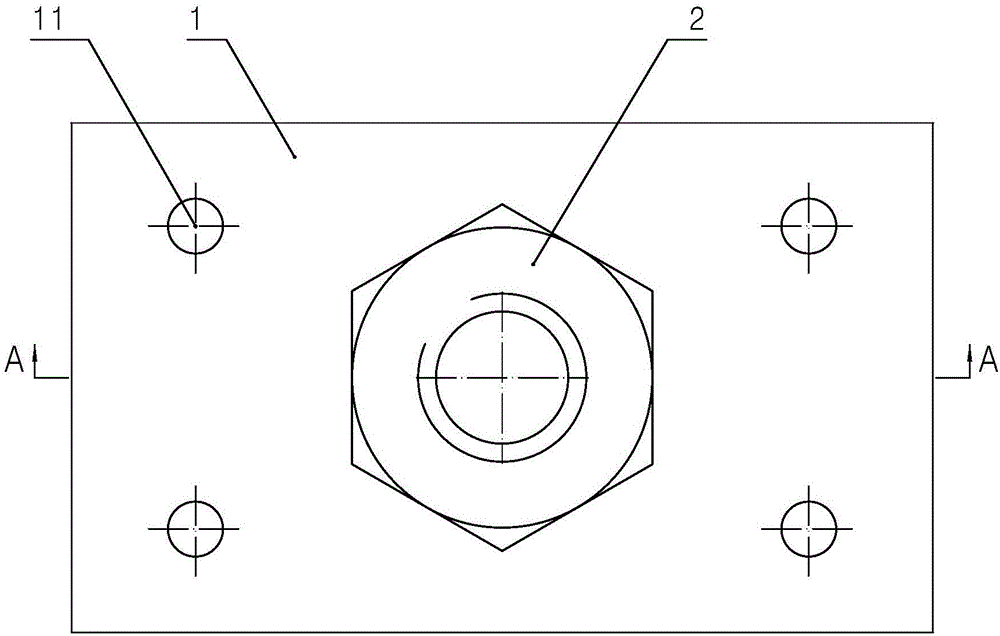

[0016] A welding method of an embedded nut connector according to the present invention, such as figure 1 As shown, the embedded nut connector includes: an installation base plate 1 provided with four installation positioning holes 11, an installation hole provided on the installation base plate 1 and matched with the inner hexagon nut 2, and the welding The method includes the following steps:

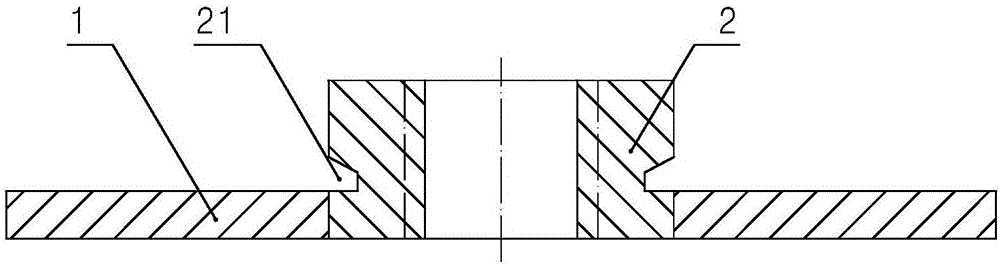

[0017] 1) if figure 2 As shown, a circumferential annular groove 21 is provided on the side of the inner hexagon nut 2 to be welded, and the depth of the annular groove 21 is less than 30% of the difference between the outer diameter and the inner diameter of the inner hexagon nut 2 , the upper side of the annular groove 21 is a slope inclined upward from the inside to the outside, the lower side of the groove 21 is a plane parallel to the bottom surface of the hexagon socket nut 2, the lower side of the annular groove 21 is to The distance of the bottom surface of the hexagon sock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com