Method for controlling an adsorption phase of a gas generator and a gas generator applying such a method

A gas generator and generator technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve problems such as endangering user processing or network, not providing remedial measures, and inefficient adsorption treatment, etc., to achieve optimal performance. energy consumption, energy consumption reduction, the effect of ensuring the desired concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

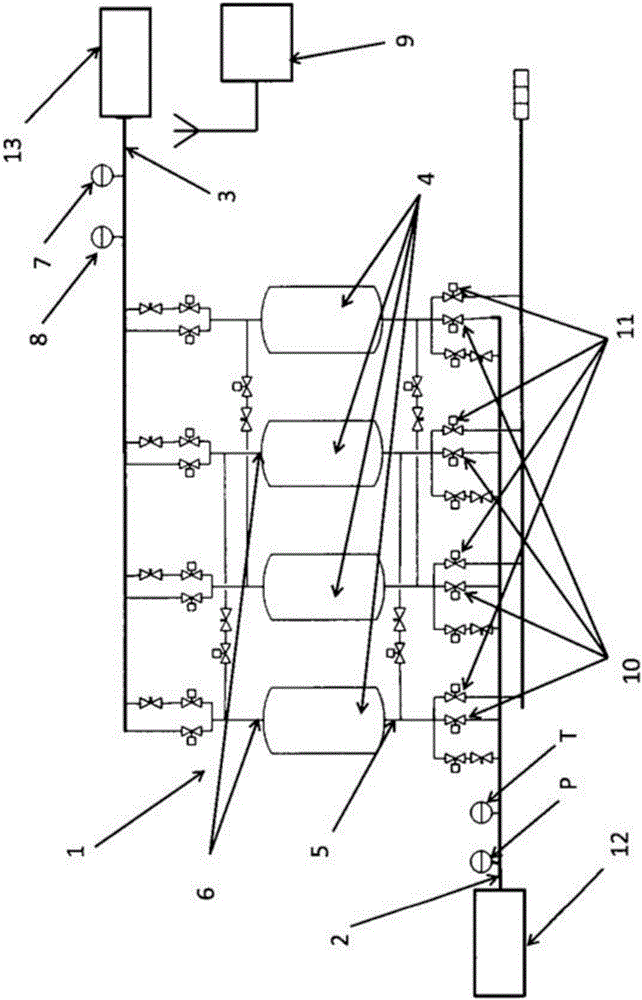

Image

Examples

example 1

[0172] Example 1: Pressure correction factor Kpc for volume , preferably but not limited to interpolation according to the following table:

[0173]

[0174]

[0175] Said first set value of concentration thus refers to said set value for the concentration of the second gas component, which can be a value preferably between 95% and 99.5%.

[0176] Said second set value of concentration refers to said set value for the concentration of the second gas component, which can be a value preferably between 99.5% and 99.999%.

example 2

[0177] Example 2: Temperature correction factor Ktc for capacity , preferably but not limited to interpolation according to the following table:

[0178]

[0179] Said first set value of concentration thus refers to said set value for the concentration of the second gas component, which can be a value preferably between 95% and 99.5%.

[0180] Said second set value of concentration refers to said set value for the concentration of the second gas component, which can be a value preferably between 99.5% and 99.999%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com