Cable protection tube mouth sealing sleeve

A technology of cable protection tubes and envelopes, which is applied in the direction of cable inlet sealing devices and electrical components, which can solve problems such as endangering the safe operation of the power grid, accumulating heavy rainwater, and declining cable insulation levels, so as to reduce operation and maintenance costs and improve work efficiency , the effect of reducing the number of power outages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

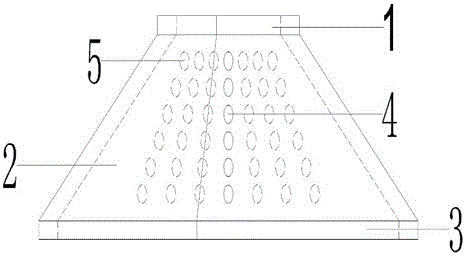

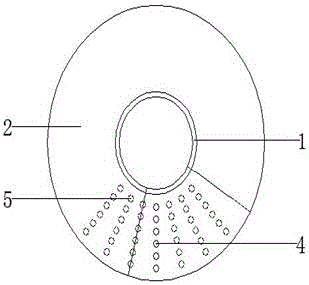

[0018] Such as Figure 1-6 As shown, a cable protection pipe mouth cover includes an upper seal 1, a cover main body 2, a lower seal 3, a buckle 4 and a concealed socket 5, the upper part of the cover main body 2 is provided with an upper seal 1, and the cover main body 2 is provided with a lower seal 3, and the upper seal 1, the envelope body 2 and the lower seal 3 are integrally casted, and a row of buckles 4 is provided on the edge of one end of the envelope body 2, and a plurality of columns are arranged at the other end Concealed sockets 5, and buckles 4 and concealed sockets 5 are evenly arranged on the surface of the main body of the envelope. According to cables 6 of different diameters, the sockets 4 are installed and fixed together with one row of concealed sockets 5.

[0019] The nozzle cover of the cable protection pipe of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com