Performance degradation analysis based intelligent manufacturing device reliability assessment method

A technology of intelligent manufacturing and reliability, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of difficult intelligent manufacturing equipment reliability characterization, real-time and efficient evaluation of reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1, a method for evaluating the reliability of intelligent manufacturing equipment based on performance degradation analysis provided by the embodiment of the present invention includes steps:

[0074] 101. Analysis:

[0075] Analyze and identify the target performance degradation indicators for on-site use that characterize the reliability of intelligent manufacturing equipment, as well as the target environment and working condition stress factors that affect its reliability.

[0076] In the embodiment of the present invention, in order to realize the efficient evaluation of the reliability of intelligent manufacturing equipment, it is first necessary to analyze and identify the data indicators that can be used for evaluation, including the target performance degradation indicators and the impact of on-site use that characterize the reliability of its use. The target environment and working condition stress factors of its reliability, etc.

[0077] 102. Col...

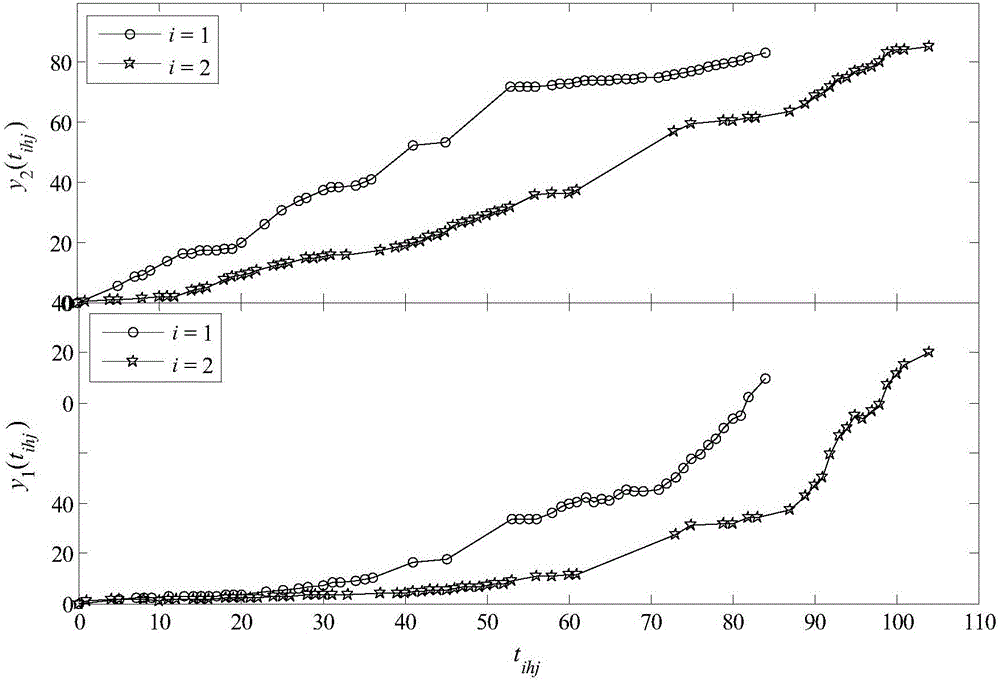

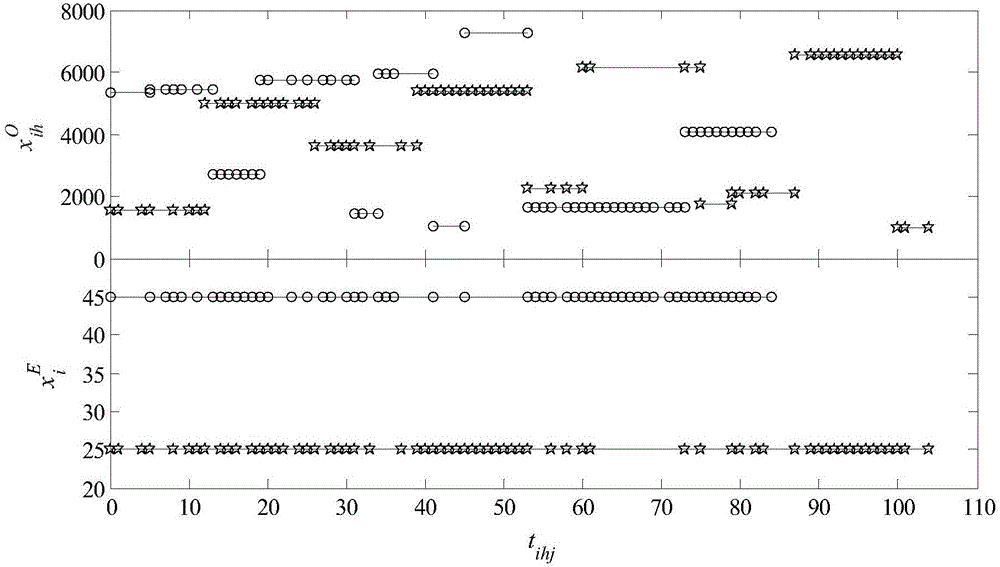

Embodiment 2

[0085]Embodiment 2, a method for evaluating the reliability of intelligent manufacturing equipment based on performance degradation analysis in the embodiment of the present invention includes the following steps:

[0086] (1) Analysis:

[0087] Analyze and identify the target performance degradation indicators for on-site use that characterize the reliability of intelligent manufacturing equipment, as well as the target environment and working condition stress factors that affect its reliability.

[0088] A1. According to the system structure and functional characteristics of an intelligent manufacturing equipment based on performance degradation analysis, carry out functional failure mode impact analysis and identify the target subsystem of the equipment;

[0089] In the embodiment of the present invention, the target subsystem of the intelligent manufacturing equipment based on performance degradation analysis includes a spindle subsystem and a hydraulic subsystem;

[0090...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com