Speed reducer for worm wheel to throw oil so as to lubricate bearing

A technology for lubricating bearings and reducers, which is applied in the directions of gear lubrication/cooling, mechanical equipment, belts/chains/gears, etc. It can solve the problems that the bearing seat cannot be effectively lubricated and affects the service life of the whole machine, so as to prolong the service life, Ensure continuous lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Further description will be made below in conjunction with drawings and embodiments.

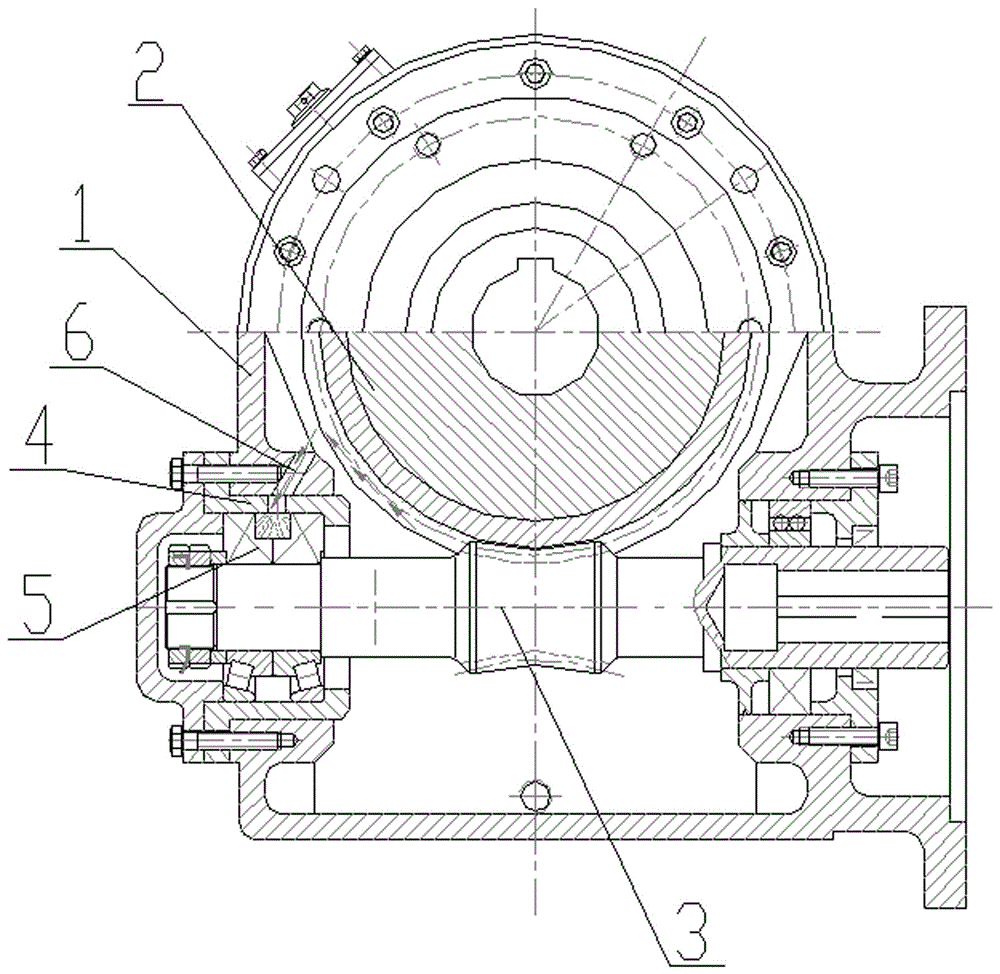

[0011] figure 1 As shown: a reducer for a worm wheel oil-lubricated bearing includes a casing 1, a worm wheel 2 and a worm 3, the worm 3 is supported in the casing through a bearing seat 4, and the inner wall of the casing below the tangential position of the worm wheel rotation above the bearing seat is set There are a plurality of oil passages 7 connected to each other through the housing and the bearing seat, and the oil passages are connected to the outer wall of the bearing 6 supporting the worm in the bearing seat.

[0012] The lubricating oil in the oil passage in the above embodiment can also be collected by setting an oil groove on the inner wall of the upper housing and then divided into multiple oil passages for simultaneous lubrication of multiple points of the bearing to improve the lubrication effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com