Sound barrier unit board based on wide band microperforated panel sound absorber and designing method thereof

A technology of micro-perforated plate and design method, which is applied in the direction of noise absorption devices, buildings, etc., can solve the problems of limited sound-absorbing band width, difficulty, and limited lifting effect of the micro-perforated plate sound-absorbing body, and achieve superior sound-absorbing performance, The effect of clear steps and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

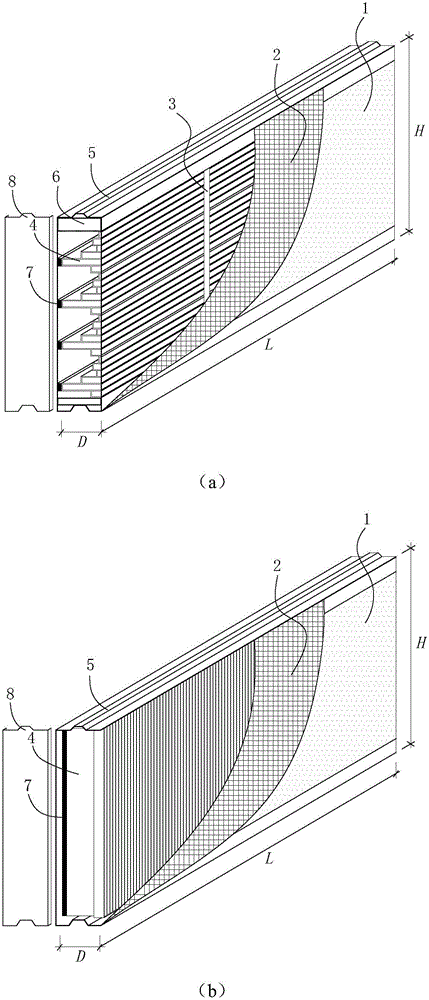

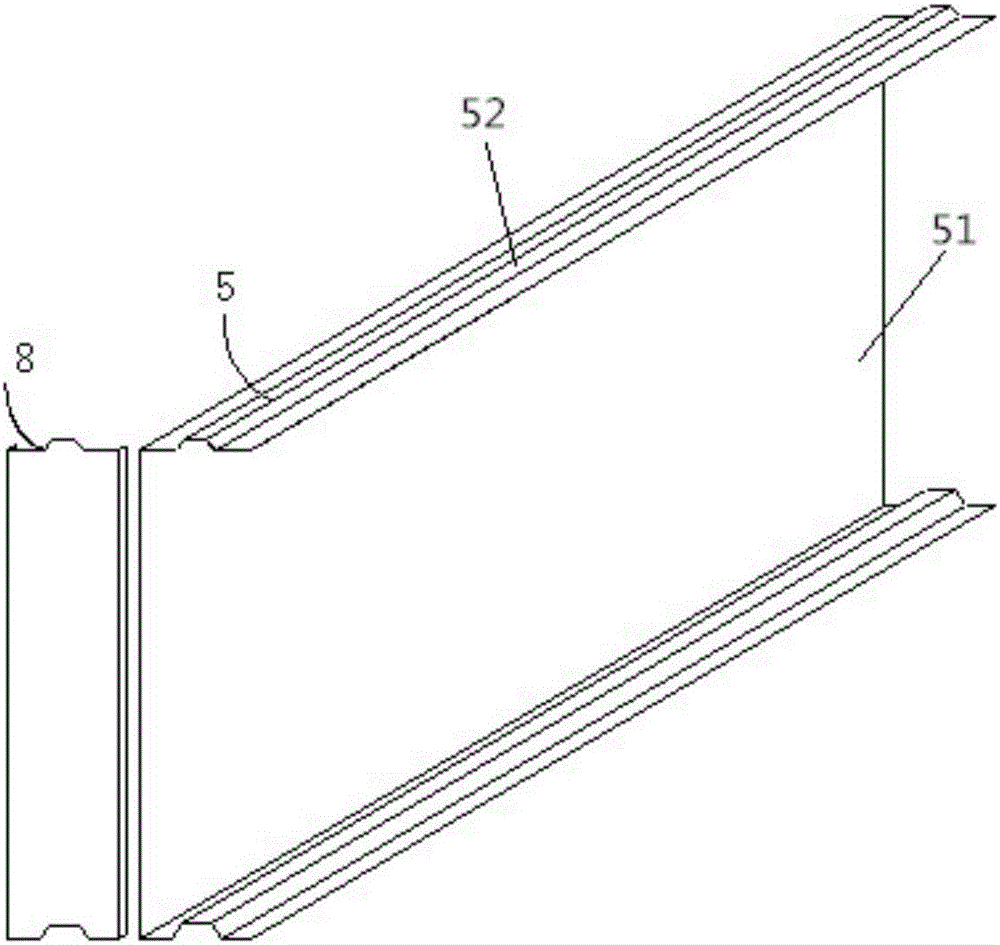

[0061] In this embodiment, based on the sound barrier unit plate of the broadband micro-perforated sound-absorbing body, the cavity group 4 with different depths is placed horizontally and horizontally on the sound-insulating back plate 5, and the perforation diameter of the micro-perforated panel 1 is 0.8mm , using non-woven fabric 2.

[0062] The height of the sound barrier unit plate is 500mm, the width is 1960mm, and the thickness is 115mm; the sound insulation back plate 5 is made of galvanized steel plate with a thickness of 0.5mm, and the head plate 8 is made of galvanized steel plate with a thickness of 1.5mm. The role of sound insulation and protection of internal sound-absorbing structures. The micro-perforated panel 1 is processed by an aluminum alloy plate with a thickness of 0.7mm, the perforation diameter is 0.8mm, the perforation arrangement is rectangular, the hole spacing is 5.5mm, and the perforation rate is about 1.66%.

[0063] Wherein, there are two short...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Perforation diameter | aaaaa | aaaaa |

| Perforation diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com