A kind of surface sizing agent and preparation method thereof

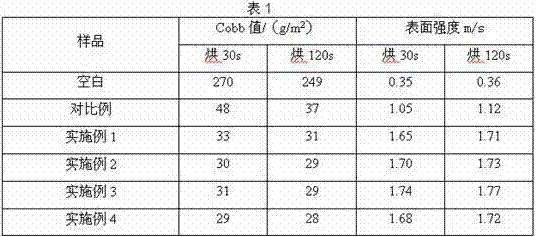

A technology of surface sizing agent and initiator, which is applied in the field of surface sizing agent and its preparation, can solve the problems of high water absorption value, difficult to improve the grade, and large amount of sizing agent, so as to improve the fiber compactness and improve the Cobb value , Strengthen the effect of cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

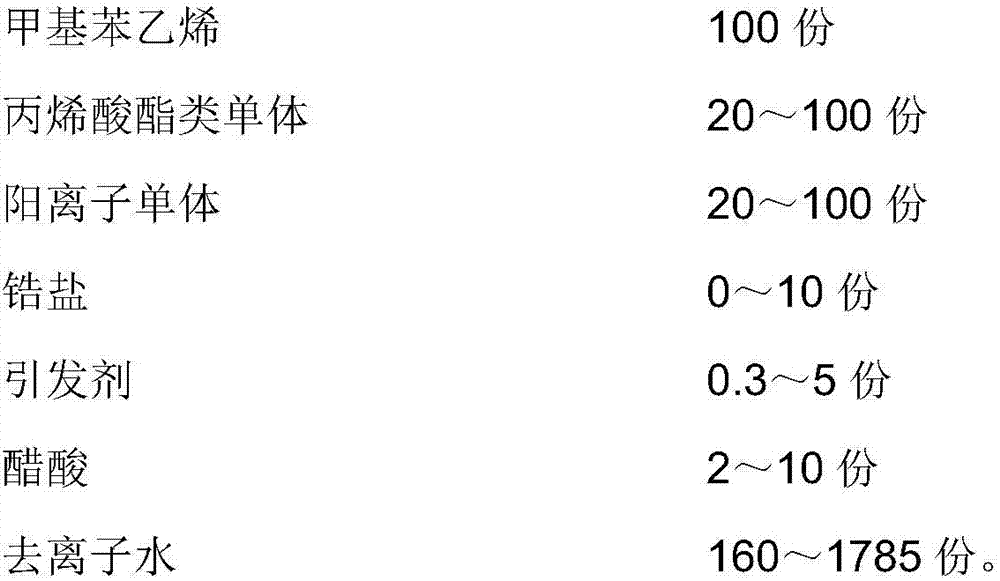

[0034] The invention provides a kind of preparation method of surface sizing agent, it is characterized in that, comprises the following steps:

[0035] Step 1, uniformly mixing methylstyrene, acrylate monomer, cationic monomer and initiator to form a mixed monomer;

[0036] Step 2, add 10% of the mixed monomer obtained in step 1 to the four-necked flask, raise the temperature to 80-140°C, react for 5-20 minutes, add the remaining mixed monomer dropwise, and then keep warm at 80-140°C for 0.5-1.5 Hour;

[0037] Step 3, adding acetic acid, reacting at 80-140°C for 20-60 minutes;

[0038] Step 4: add deionized water preheated at 80-100°C, continue to react for 0.5-2 hours, cool to 25-35°C, add zirconium salt, stir evenly, and filter to obtain a surface sizing agent.

Embodiment 1

[0041] Preparation of surface sizing agent:

[0042] A) Mix 100 grams of styrene, 20 grams of n-butyl acrylate, 20 grams of N,N-dimethylaminoethyl acrylate, and 0.3 grams of dibenzoyl peroxide, and set aside.

[0043] B) Heat 161.47 g of deionized water to 80°C and set aside.

[0044] C) Add 10% of the mixed monomer in step A) to a four-neck flask equipped with a condenser, dropping device, stirrer, and thermometer, raise the temperature to 80°C, and add dropwise the remaining The mixed monomers were added dropwise for 5 hours. After the dropwise addition, the heat preservation was continued at 80°C for 1 hour, and then 10 g of acetic acid was added. After reacting at 80°C for 1 hour, the hot water in step B) was added, reacted for 1 hour, and cooled to 35 °C, pH=1.13. After filtering through a 100-mesh filter screen, the obtained surface sizing agent had a solid content of 44.93wt%.

Embodiment 2

[0046] Preparation of surface sizing agent:

[0047] A) Mix 100 grams of methyl styrene, 100 grams of isooctyl acrylate, 100 grams of methacrylamidopropyl dimethylamine, and 5 grams of tert-butyl peroxybenzoate, and set aside.

[0048] B) Heat 1783 grams of deionized water to 100°C and set aside.

[0049] C) Add 20% of the mixed monomers in step A) to a four-neck flask equipped with a condenser, dropping device, stirrer, and thermometer, raise the temperature to 140°C, add, and add step A) dropwise after 10 minutes of reaction Add the remaining mixed monomer in the mixture for 1 hour. After the dropwise addition, continue to keep warm at 140°C for 0.5 hour, then add 2 grams of acetic acid, react at 140°C for 20 minutes, add the hot water in step B), and cool down to 95°C for reaction After 30 minutes, cool to 25°C, add 10 grams of zirconium carbonate, stir evenly, pH=5.98. After filtering through a 100-mesh filter screen, the obtained surface sizing agent had a solid content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com